10 english

4.3 Installing the transducer

NOTICE!

Interference in function

Improper installation can compromise the function of the

transducer and result in increased wear.

Ź The mounting surface of the transducer must make

full contact with the supporting surface.

Ź The bore must be perfectly sealed (O-ring/flat seal).

Ź Make a mounting hole with thread (possibly with

countersink for the O-ring) acc. to Fig. 4-3 or Fig. 4-4.

Ź Screw the transducer with mounting thread into the

mounting hole (max. torque100Nm).

Ź Install the magnet (accessories).

Ź For nominal lengths>500mm: Tighten the rod at the

end (only possible with Ø10.2mm) or support it.

Suitable nuts for the mounting thread are

available as accessories (see page25).

4.3.1 Installation recommendation for hydraulic

cylinders

If you seal the hole with a flat seal, the max. operating

pressure will be reduced in accordance with the larger

pressurized surface.

If installing horizontally in a hydraulic cylinder (nominal

lengths>500mm), we recommend affixing a sliding

element to protect the rod end from wear.

Dimensioning of the detailed solutions is the

responsibility of the cylinder manufacturer.

The sliding element material must be suitable for the

appropriate load case, medium used, and application

temperatures. E.g. Torlon, Teflon or bronze are all possible

materials.

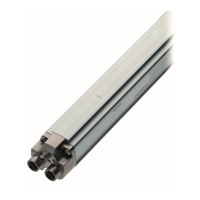

Fig. 4-5:

Example 1, transducer installed with sliding element

The sliding element can be screwed on or bonded.

Ź Secure the screws so they cannot be loosened or lost.

Ź Select a suitable adhesive.

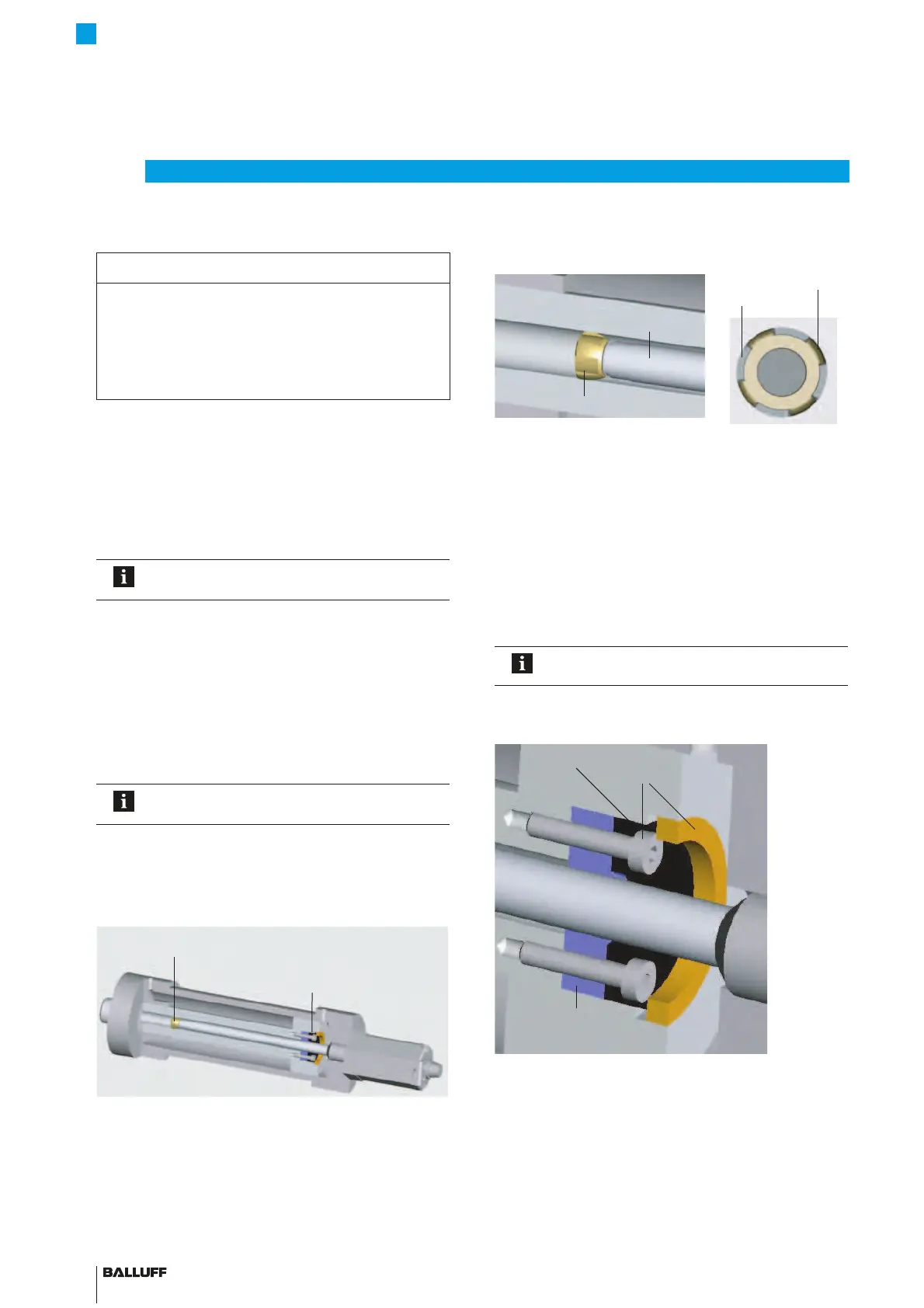

Fig. 4-6: Detailed view and top view of sliding element

There must be a gap between the sliding element and

piston bore that is sufficiently large for the hydraulic oil to

flow through.

Options for fixing the magnet:

– Screws

– Threaded ring

– Press fitting

– Notches (center punching)

If installed in a hydraulic cylinder, the magnet

should not make contact with the rod.

The hole in the spacer ring must ensure optimum guidance

of the rod by the sliding element.

Fig. 4-7:

Fixing the magnet

An example of how to install the transducer with a

supporting rod is shown in Fig. 4-8 on page11.

4

Installation and connection (continued)

Slide element

Magnet

Piston rod

BTL rod

Slide element

Flow gap

Slide surface

Magnet

Fixing of magnet

Spacer ring

BTL7-A/C/E/G_ _ _-M_ _ _ _-A/B/Y/Z(8)-S32/S115/S135/S140/KA_ _/FA_ _

Micropulse Transducer - Rod Style

Loading...

Loading...