Bandit

82

Copyright 12/17

MODEL 20XP

HYDRAULIC SYSTEM TROUBLE SHOOTING

Before attempting any type of maintenance, disengage clutch, wait for the disc/drum to come to a complete

stop, turn o engine, remove the ignition key, make sure the ignition key is in your possession, install the

disc/drum lock pin, and disconnect the battery.

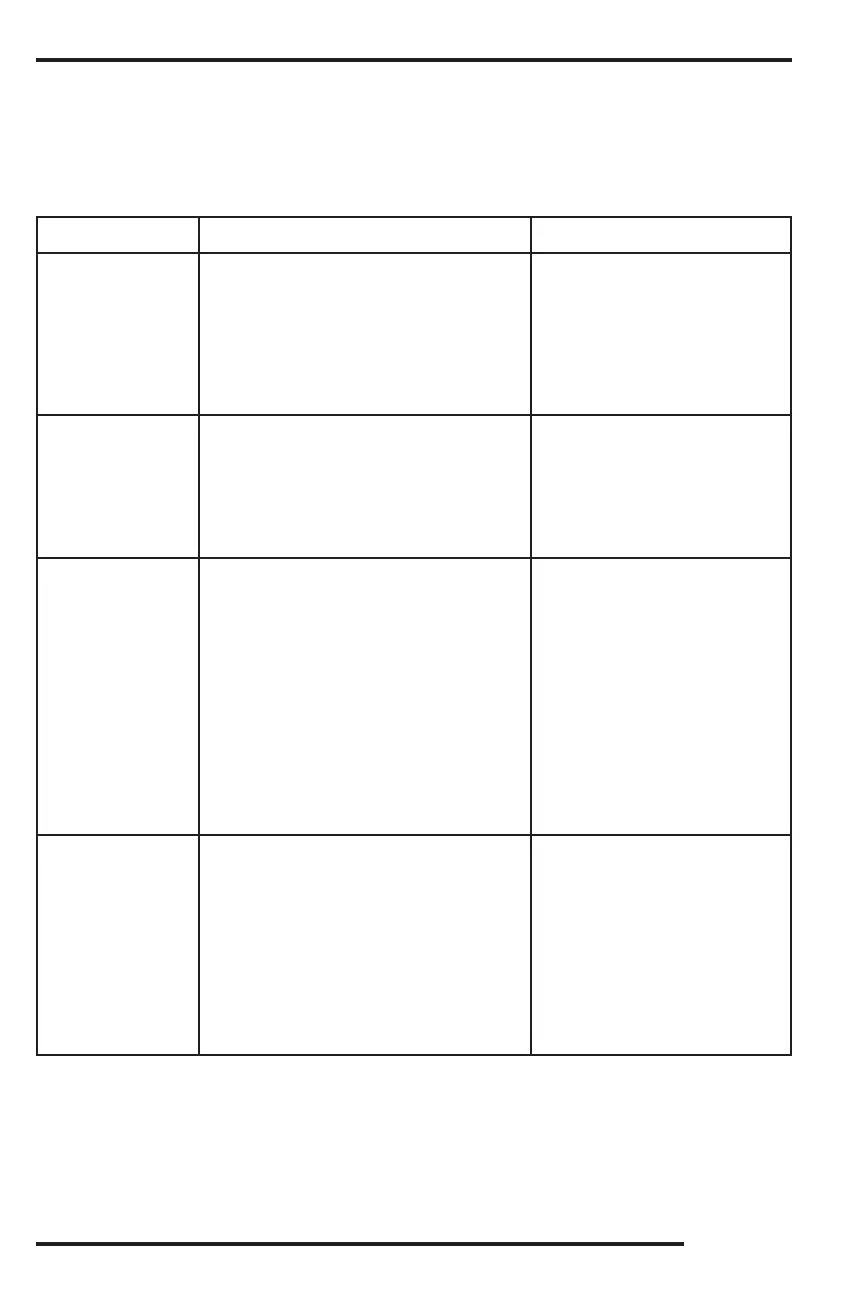

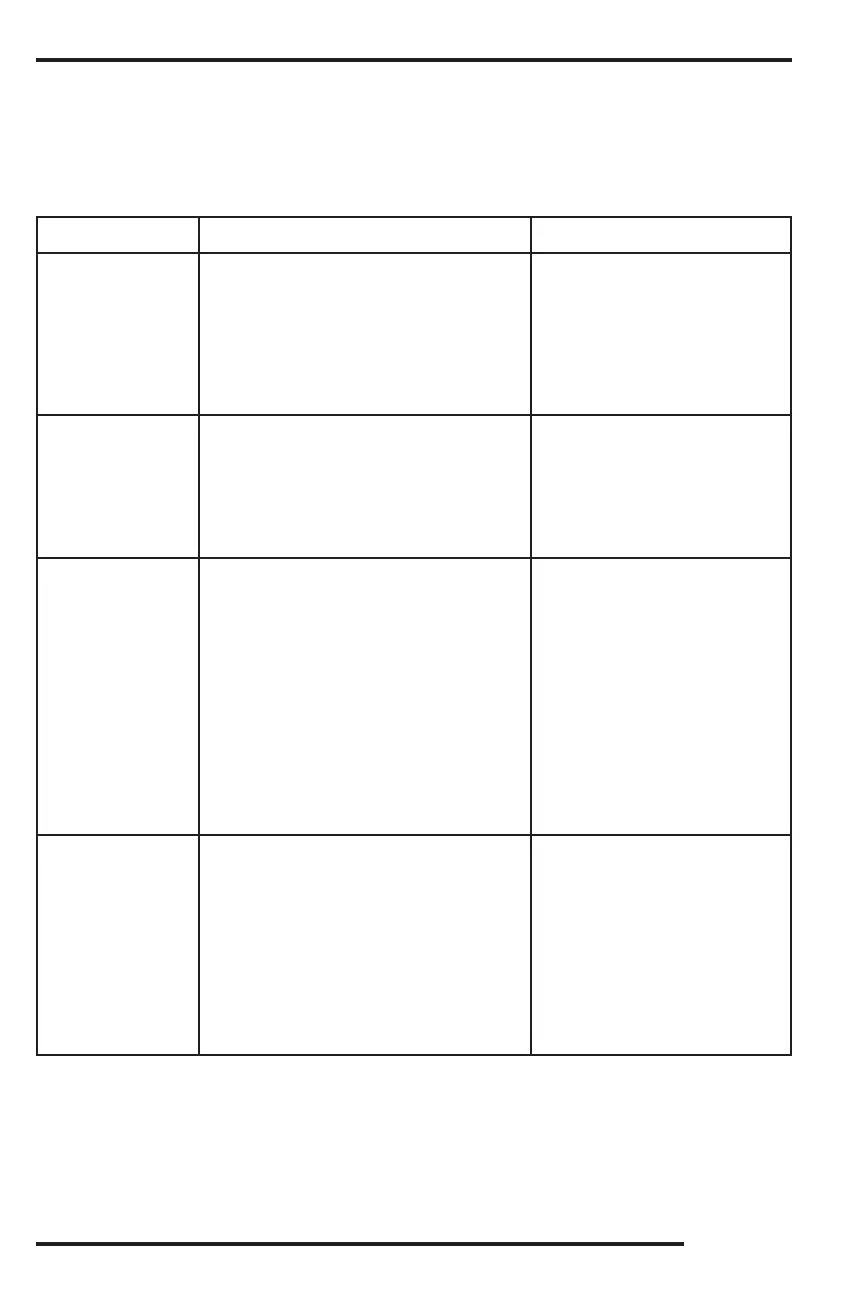

PROBLEM POSSIBLE CAUSE SOLUTION

Feedwheel(s) turn

at normal speed

but does not chip

wood properly

1. Dull knives

2. Worn feed teeth

3. Low feedwheel relief valve setting

4. Pump is worn

5. Motor is weak

6. Feedwheel springs too loose

7. Clutch / belts out of adjustment

8. Engine not running at full RPMs

1. Replace knives

2. Replace

3. Readjust to specified PSI (bar)

4. Replace

5. Replace

6. Adjust

7. Adjust

8. Adjust

Feedwheel(s)

slow or stop when

feeding

1. Dull knives

2. Relief valve is worn or dirty

3. Pump is worn

4. Motor is worn

5. Feedwheel springs too tight

6. Feedwheel slide box sticking or hanging

up

1. Replace knives

2. Clean, reset, or replace

3. Replace

4. Replace

5. Adjust

6. Lubricate

Feedwheel(s) turn

slowly or not at all

1. Relief valve stuck open

2. Worn hydraulic motor

3. Pump is worn

4. Feedwheel relief pressure not correct

5. Pinched or damaged hydraulic hose

6. Feedwheel valve (control valve) worn &

leaking internally

7. Autofeed dump valve stuck open

8. Low hydraulic oil level

9. Plugged oil screen

10. Binding such as worn bearings, etc.

11. Control lever improperly shifting valve

1. Clean or replace

2. Replace

3. Replace

4. Reset to specified PSI (bar)

5. Replace

6. Replace

7. Lightly tap on dump block,

remove & clean, or replace

8. Fill 3/4” to 7/8” full

9. Replace

10. Repair

11. Readjust, valve must open

completely

Hydraulic oil

very hot, causing

system to operate

slowly

1. Dull knives

2. Low oil level

3. Pump is worn

4. Relief valve stuck open or opens easily

5. Damaged hose

6. Oil suction screen or filter plugged

7. Oil cooler plugged, if equipped

8. Motor is worn

9. Binding

10. Operator running oil over relief too much

11. Flow control is on for too long

1. Replace knives

2. Fill 3/4” to 7/8” full

3. Replace

4. Clean, reset, or replace

5. Replace

6. Clean or replace

7. Clean

8. Replace

9. Repair

10. Do not do this

11. Open flow control

MAINTAIN FEEDWHEEL HYDRAULIC PRESSURE AT SPECIFIED PSI (bar)

Follow typical hydraulic ow and relief settings on pages 76 - 81.

Follow proper hydraulic oil requirements on pages 74 - 75.

Loading...

Loading...