Technical data

38 8LS...-3 user's manual V2.50

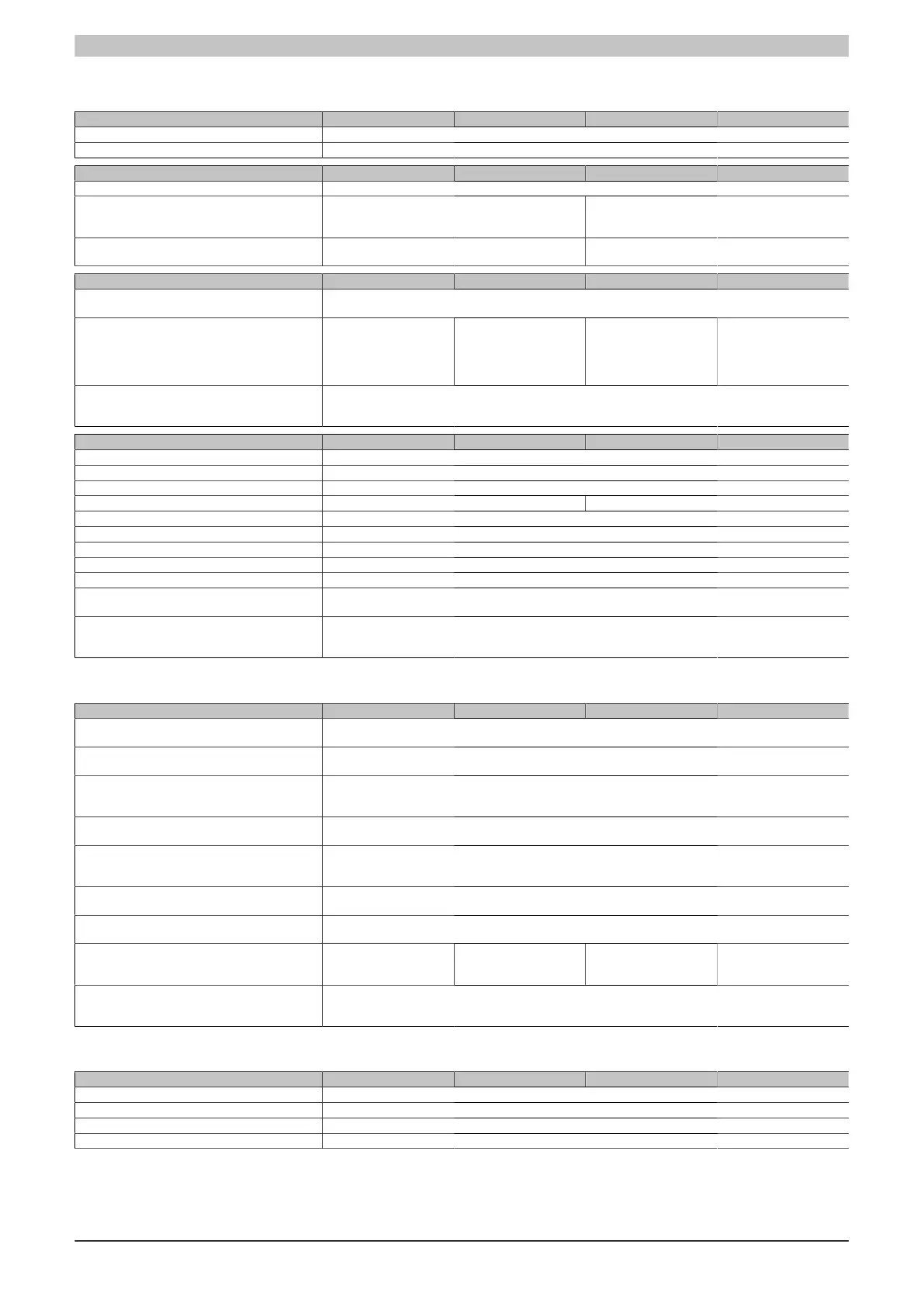

2.12 General motor data

General information 8LSA 8LSC 8LSO 8LSP

C-UR-US listed Yes

UL file number E235396

Electrical properties 8LSA 8LSC 8LSO 8LSP

Mains input voltage on servo drive 3x 400 VAC ... 3x 480 VAC ±10%

Connection type - Conventional:

Power connection:

Encoder connection:

speedtec circular connector from Intercontec

Size 1 and 1.5

Size 1

Terminal box

M10 or M12

speedtec circular connector from Intercontec, size 1

Connection type - Single-cable solution (hybrid) speedtec/htec circular con-

nector from Intercontec, size 1

---

Thermal properties 8LSA 8LSC 8LSO 8LSP

Insulation class of the isolation system per

EN 60034-1

F

Methods of cooling per EN 60034-6 (IC code) Self-cooling, free

circulation surface

cooling (IC4A0A0)

External cooling, sur-

face cooling with ma-

chine-mounted in-

dependent fan com-

ponent (IC4A0A6)

Self-cooling, free

circulation surface

cooling (IC4A0A0)

External cooling, sur-

face cooling with ma-

chine-mounted in-

dependent fan com-

ponent (IC4A0A6)

Thermal motor protection per EN 60034-11 Maximum winding temperature is 155°C (limited by the thermal motor protection in the ACOPOS servo

drive or in the ACOPOSmulti drive system to 110°C with EnDat feedback and 130°C with resolver feedback)

KTY83-110 / AM-PTC1000

Mechanical properties 8LSA 8LSC 8LSO 8LSP

Vibration severity per EN 60034-14 Vibration severity level A

1)

Bearing service life calculation DIN ISO 281

Center hole per DIN 332 Form F

Eye bolt per DIN 580 Starting with size 8 Yes

Shaft end per DIN 748

2)

Form E

Oil seal per DIN 3760 Form A

Key and keyway per DIN 6885-1 Form A keys, form N1 keyway

Balancing of shaft per DIN ISO 8821 Shaft and fitment key convention

Mounting flange per DIN 42948 Form A

Radial runout, concentricity and axial runout of

mounting flange per DIN 42955

Tolerance R

Coating:

Description:

Color:

Water-based coating

98160 *IDROLIN/E SM SEMIOPACO NERO RAL 9005-C.452

RAL 9005 flat; shaft end and flange front metallic glossy

1)

Valid for all motors with a shaft height greater than 56 mm.

2)

Except size 2, regular and reinforced bearing in sizes 5, 7 and 8

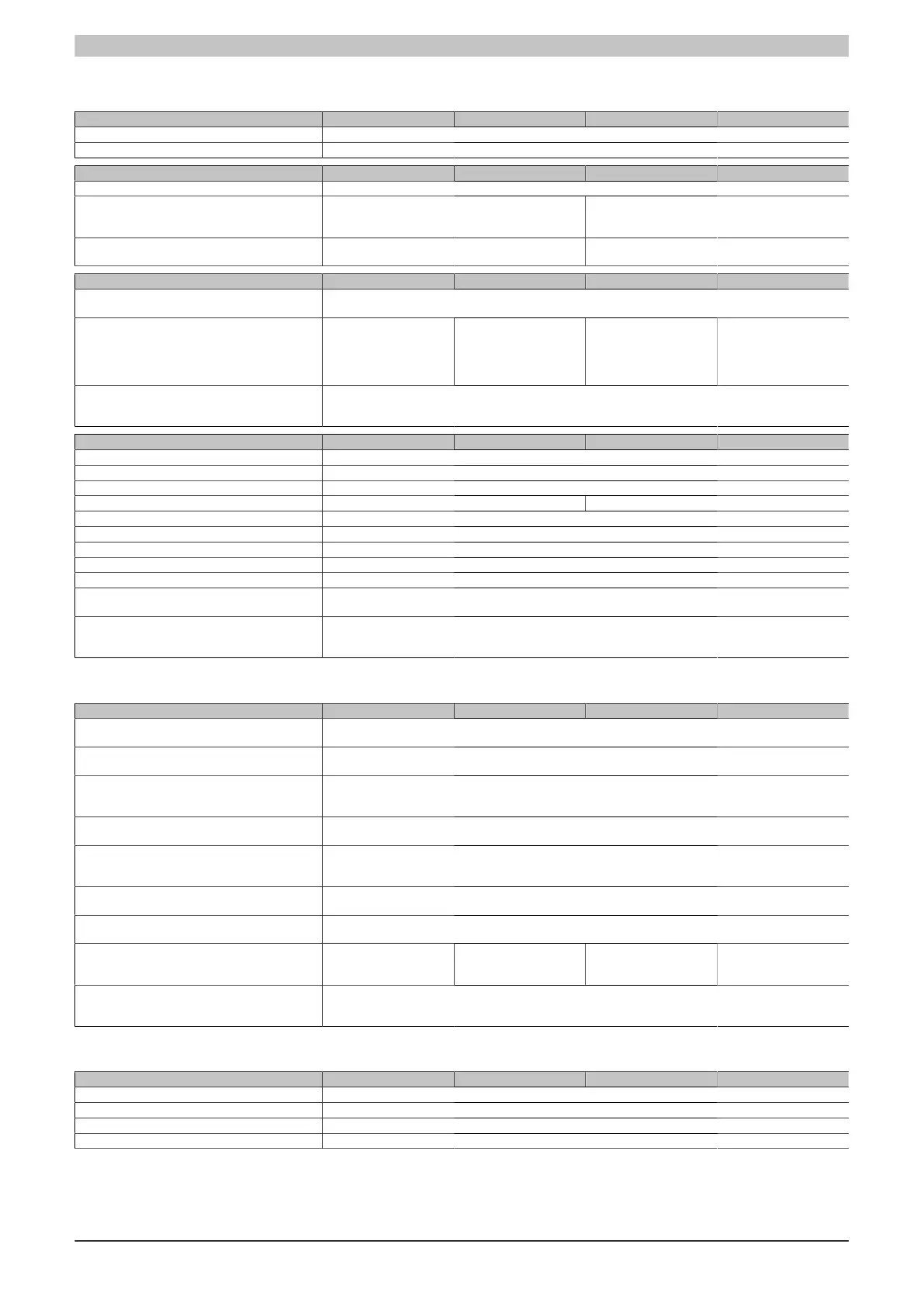

Operating conditions 8LSA 8LSC 8LSO 8LSP

Rating class, operating mode per EN 60034-1 S1 - Continuous operation

Ambient temperature during operation -15°C to +40°C

Reduction of nominal and stall current as well as

nominal and stall torque at temperatures above

40°C

10% per 10°C

Max. ambient temperature during operation +55°C

1)

Reduction of nominal and stall current as well as

nominal and stall torque at installation elevations

starting at 1,000 m above sea level

5% per 1000 m

Maximum installation elevation 2000 m

2)

Max. flange temperature 65°C

EN 60034-5 protection (IP code):

Degree of protection with optional oil seal (DIN

3760):

IP64

IP65

IP64, fan IP20

IP65, fan IP20

IP64

IP65

IP64, fan IP20

IP65, fan IP20

Type of construction and mounting arrangement

per EN 60034-7 (IM code)

Horizontal (IM3001)

Vertical, motor hangs on the machine (IM3011)

Vertical, motor stands on the machine (IM3031)

1)

Continuous operation of the servo motors at an ambient temperature of 40°C to max. 55°C is possible, but this results in premature aging.

2)

Requirements that go beyond this must be arranged with B&R.

Storage and transport conditions 8LSA 8LSC 8LSO 8LSP

Storage temperature -20 to +60°C

Relative humidity during storage Max. 90%, non-condensing

Transport temperature -20 to +60°C

Relative humidity during transport Max. 90%, non-condensing

Loading...

Loading...