Tab.25 Checking and setting values for gas type G25

U

Unit POWER HT+ 1.50 POWER HT+ 1.70 POWER HT+ 1.90 POWER HT+ 1.110

Diameter of the Venturi mm 24 30 34 38

Diameter of the nozzles mm 4.20 (no. 2) Variable mixer

nozzles: top part

with a diameter of

5.70 mm, bottom

part with a diame

ter of 6.50 mm.

6.30 (no. 2) Variable mixer noz

zles: top part with a

diameter of 6.80

mm, bottom part

with a diameter of

7.70 mm.

Minimum CO

2

(1)

% 8.5 8.6 8.6 9.0

Maximum CO

2

(1)

% 8.9 8.9 8.8 9.1

Maximum CO ppm < 250 < 250 < 250 < 250

Tab.26 Checking and setting values for gas type G31

Unit POWER HT+ 1.50 POWER HT+ 1.70 POWER HT+ 1.90 POWER HT+ 1.110

Diameter of the Venturi mm 24 30 34 38

Diameter of the nozzles mm 2.95 (no. 2) 4.0 (no. 2) 4.5 (no. 2) 5.0 (no. 2)

Minimum CO

2

(1)

% 9.5 9.5 9.9 9.5

Maximum CO

2

(1)

%10 10 10 10

Maximum CO ppm < 250 < 250 < 250 < 250

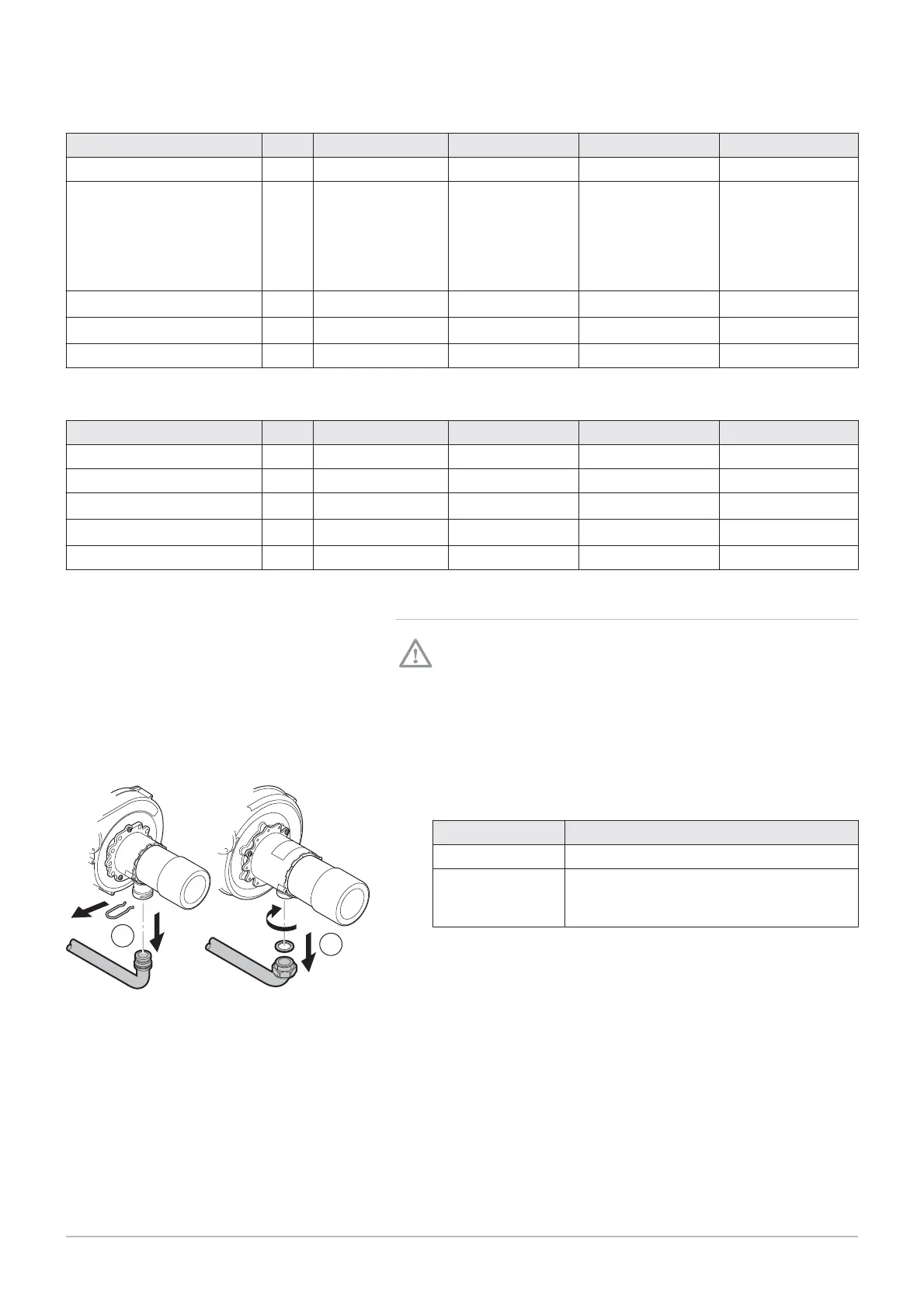

7.4.6 Adapting to another gas type

Caution

Only a fully trained, qualified professional may carry out the follow

ing operations.

The boiler is pre-set in the factory to run on natural gas H

.

Conversion kits are available for other types of gas G

and G

.

1. Close the mains gas valve.

2. Remove the pipe connecting the Venturi to the gas valve.

Tab.27 Connection differences

POWER HT+ 1.50

POWER HT+ 1.70

POWER HT+ 1.90

POWER HT+ 1.110

Fig.68 Removing the connection pipe

MW-3000048

A

2

2

B

7 Commissioning

7609474 - v02 - 04092014 63

Loading...

Loading...