B. Turn gas supply ON to oven and check for

leaks between gas valve and supply line

shut-off valve.

C. Verify that the static line pressure to the

oven does not exceed 14" W.C. (1/2 psig,

35.6 cm W.C., 3.5 kPa)

NOTE:

If static line pressure exceeds 14" W.C. (1/2

psig, 35.6 cm W.C., 3.5 kPa) the customer must

supply and install a line pressure regulator to drop the

pressure below 14" W.C., 35.6 cm W.C., 3.5 kPa

D. Turn gas valve ON.

E. Set the oven to call for heat.

NOTE: It may take several ignition attempts to light

burner initial time.

F. With oven burner flame established and with

the burners lit for all other equipment that

are common to supply line, check

SUPPLY

FLOW PRESSURE CHARTS.

G. With a burner flame established, adjust

manifold pressure as indicated on the oven

data plate

.

NOTE: The

ALTITUDE CORRECTION CHARTS are

for reference only. If the manifold pressure must be

adjusted to

accommodate the installation altitude you

must contact Bakery Product Support for a corrected

data plate.

12. Initial heating of oven.

A. Press the VENT key to open baking

chamber vent.

B. Leave loading door ajar approximately 2" to

evacuate smoke and prevent tarnishing of

oven interior, but not open far enough to

prevent operation of oven.

C. Set the oven control baking temperature to

300°F (150°C.). and bake timer for 30

minutes.

D. After time elapses, press STOP key to

silence beeper.

E. Fully open loading door to verify that baking

compartment circulation blower de-

energizes.

F. Set the oven control baking temperature to

400°F (200°C.). and bake timer for 30

minutes. Leave loading door ajar

approximately 2".

G. After time elapses, silence the beeper and

allow oven to heat for an additional 30

minutes with loading door closed.

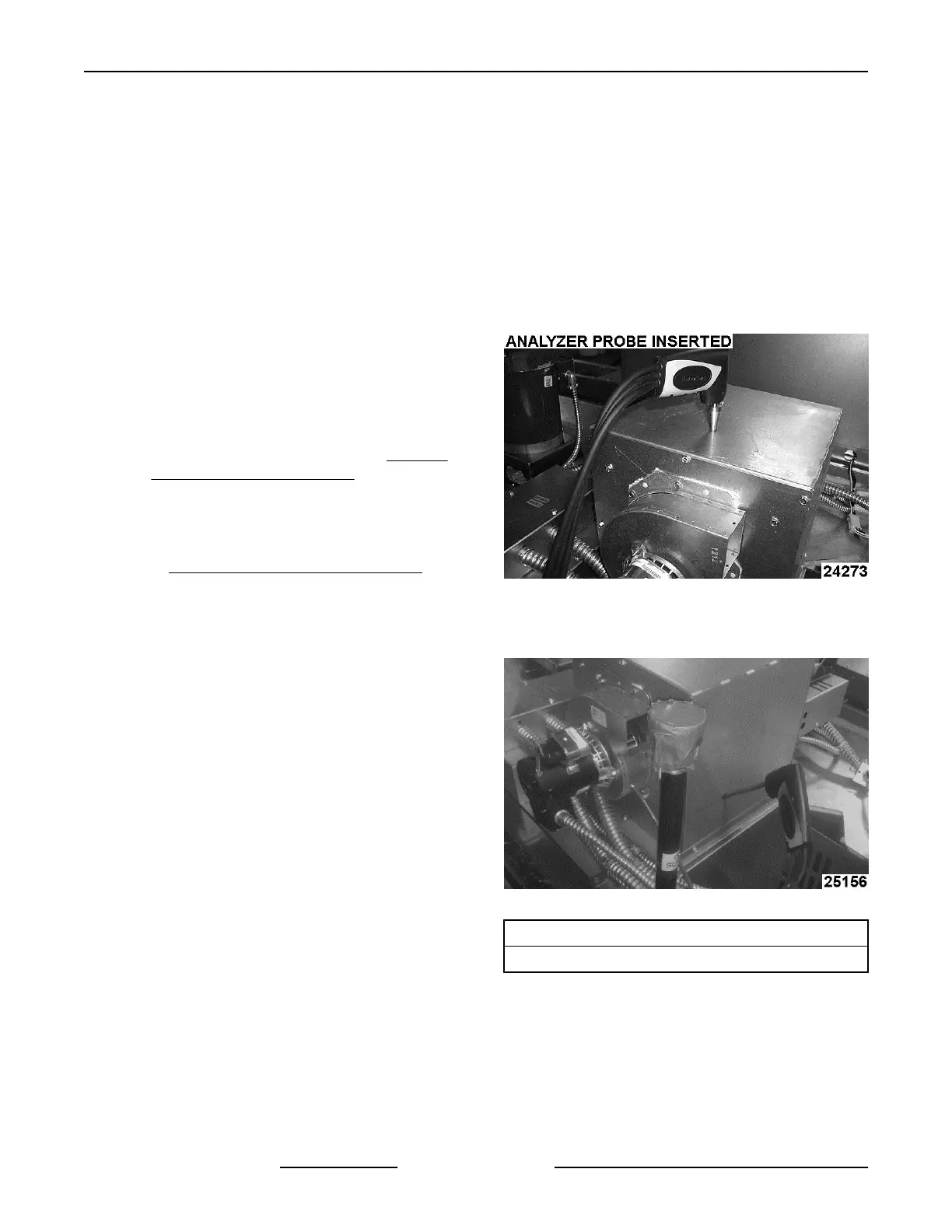

13. Combustion analysis.

A. Allow oven to cool to 300°F (150°C.).

B. Set oven temperature to 450°F (230°C.) and

with burner flame established, insert

combustion analyzer meter into air sampling

hole and take combustion measurements

O2 and CO air free readings.

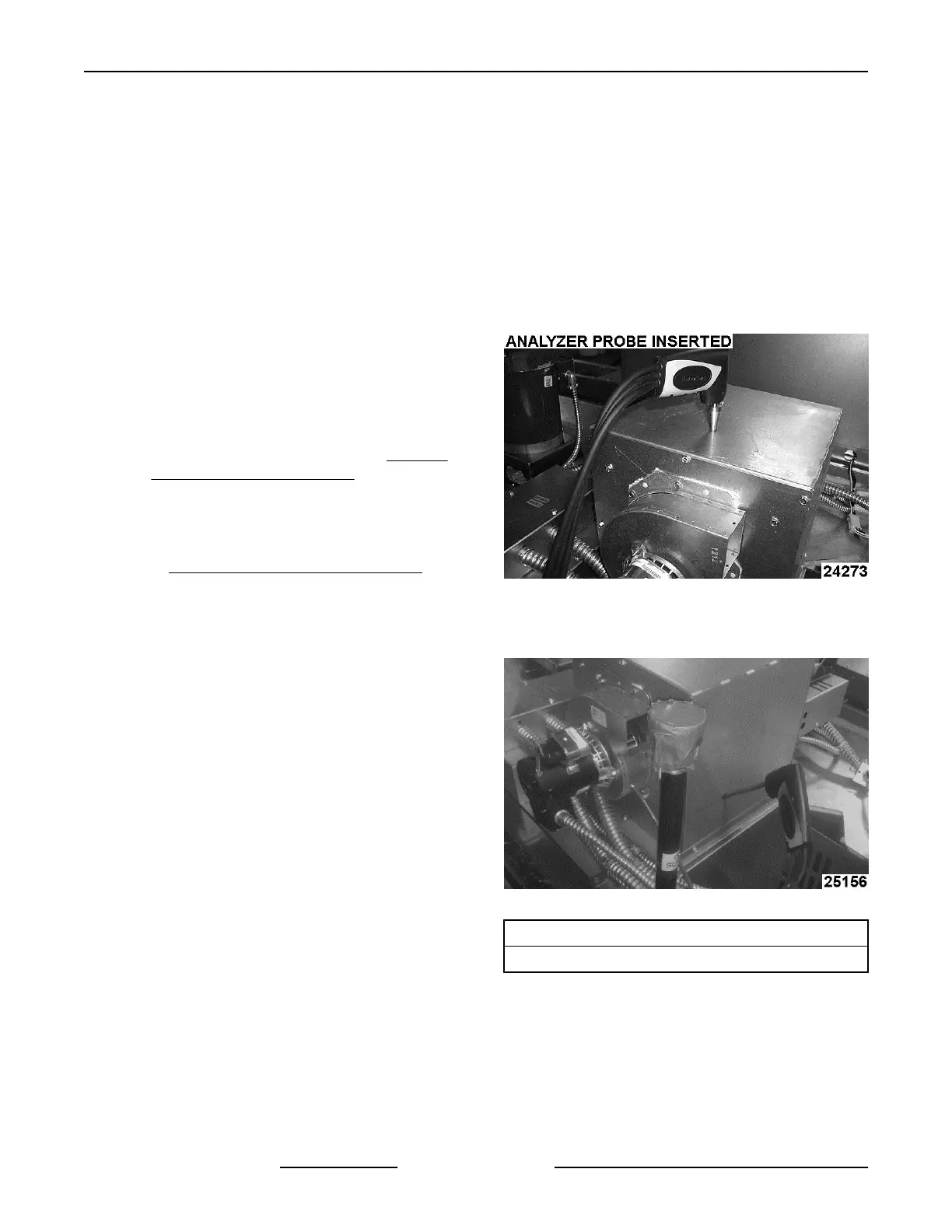

NOTE: Location of the air sampling hole will be either

on top of, or on the side of the draft inducer assembly.

Refer to pictures below for location of air sampling

hole.

Fig. 127

NOTE: If air sampling hole is on the side, insert the

probe at a 45° angle.

Fig. 128

O2: ( Range 6% to 8%)

CO Air Free: Not to exceed 0.04% (400PPM)

1) If reading can not be obtained, adjust

the draft inducer baffle and retest for

combustion.

INSTALLATION INSTRUCTIONS OV500-EE SERIES GAS RACK OVENS AND OV500 SERIES ELECTRIC RACK

OVENS - INSTALLING OVEN

F45469 Rev. D (1019) Page 46 of 49

Loading...

Loading...