BA series pumps

1401 Maintenance

9.9

WARNING

Use the same type of lubricating oil the bearing was originally provided with. Some

types of lubricating oil are incompatible and if mixed can cause severe damage to

the bearings and the pump.

Fill quantity

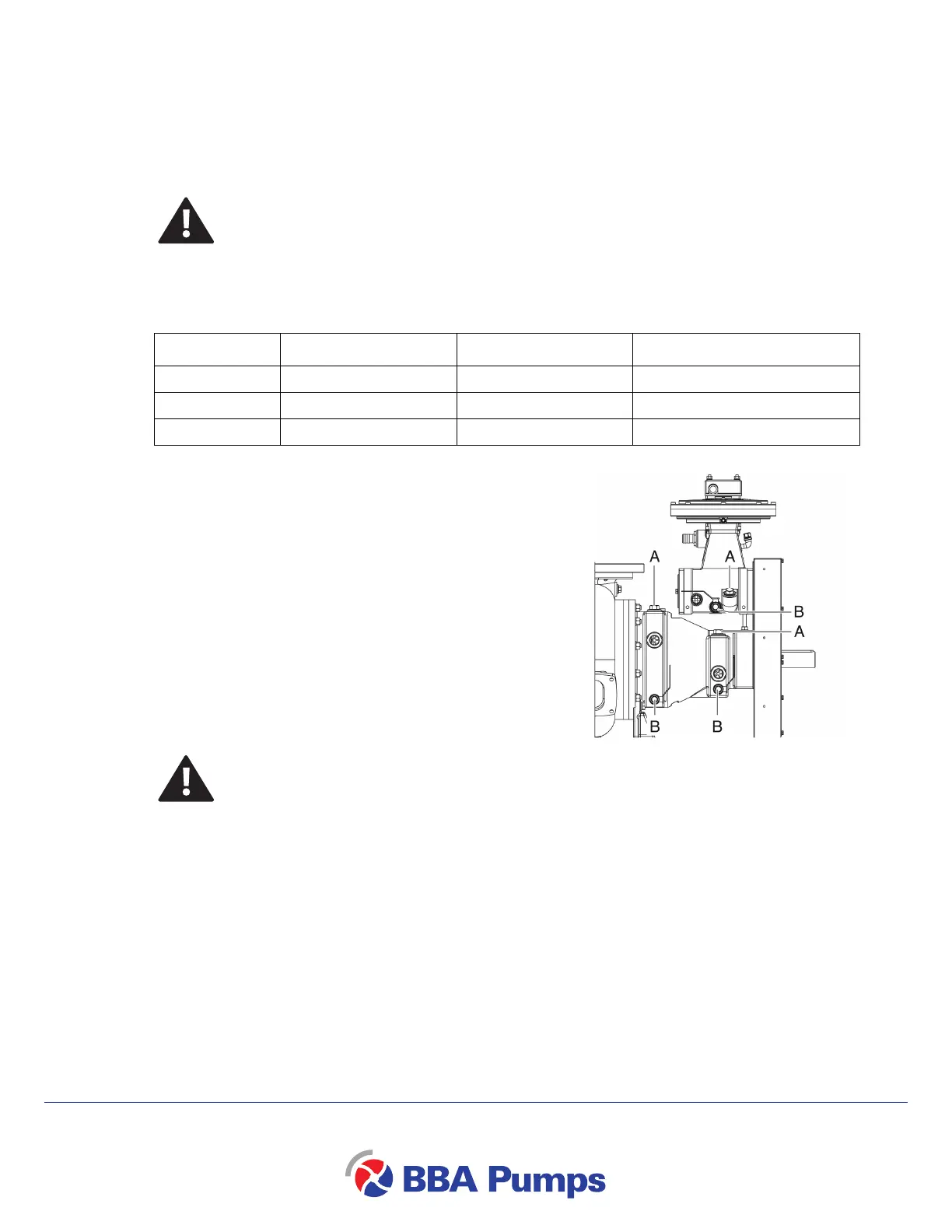

1. Remove the fill plugs (A).

2. Place a suitable drain pan under the drain plug or valve

(B).

3. Remove the plug or open the valve.

4. Allow the oil to drain thoroughly.

5. Re-install the drain plug with a new seal or close the

valve.

6. Fill the chamber with the prescribed oil until the level

reaches the middle of the sight glass.

7. Re-install the drain plug with a new seal.

8. Dispose of the oil in a responsible manner.

WARNING

The maximum oil level must always be

visible in the sight glass. The pump can be damaged by an excessive oil level.

Checking the suction strainer and/or filter for contamination

1. When using a suction strainer and/or suction filter, check whether the inlet pressure at the suction

flange of the pump is within the permissible range (see the NPSH graph that corresponds to the

pump type).

2. Clean the suction strainer and/or filters regularly. The required cleaning interval depends on the

pumped liquid and its level of contamination.

Pump type Shaft seal Pump bearings Vacuum pump bearings

BA 100 2.5 litre (0.55 gallon) 1.2 litre (0.26 gallon) 0.6 litre (0.13 gallon)

BA 150 2.5 litre (0.55 gallon) 1.2 litre (0.26 gallon) 0.6 litre (0.13 gallon)

BA 200 2.5 litre (0.55 gallon) 1.2 litre (0.26 gallon) 0.6 litre (0.13 gallon)

Loading...

Loading...