BA series pumps

1401 Troubleshooting tables

10.1

10 Troubleshooting tables

WARNING

In the event of a malfunction or abnormal operation, shut off the pump or pump unit

immediately to prevent a dangerous situation and/or damage (possibly severe) to

the pump or pump unit.

Inform to responsible persons. Determine the cause of the malfunction. Resolve the

problem before restarting the pump.

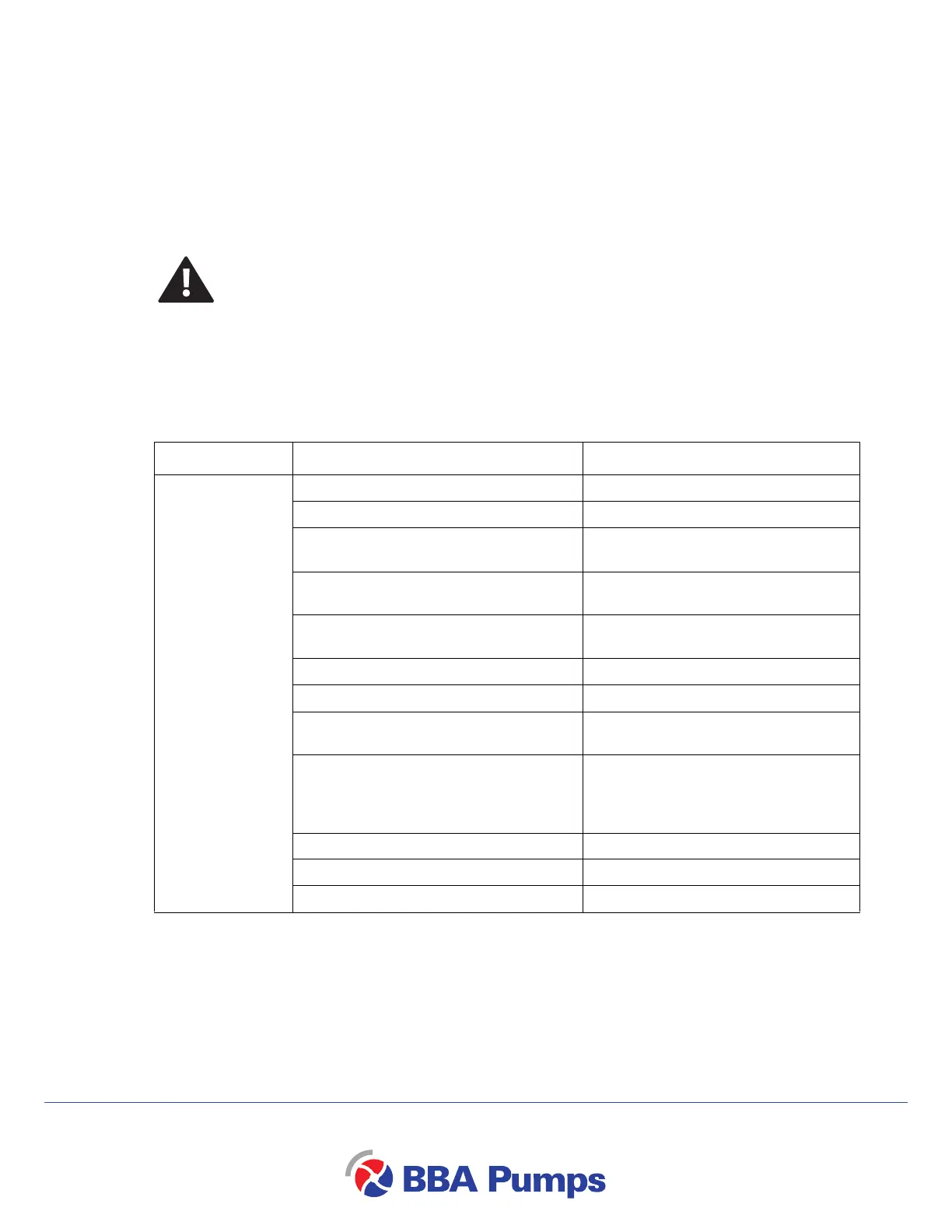

10.1 Troubleshooting table – pump (general)

Problem Cause Possible solution

Pump does not

deliver any liquid

Incorrect direction of rotation Reverse direction of rotation

Vacuum pump does not draw a vacuum Inspect vacuum pump

Gas or air is released from the liquid Ensure that the liquid flows more slowly/

smoothly

Air pockets form in the suction line Eliminate air entrapment to the extent

possible

Inlet of the suction pipe is insufficiently

submerged

Submerge the suction line more deeply

Foreign object in the impeller Clean impeller

Insufficient lubrication Lubricate

Manometric suction height undercalculated Place pump higher, if possible

Otherwise: use a different type of pump

The suction height is too great or there is

too little difference between the geometric

height and the vapour tension of the liquid

(NPSH too low)

Place pump at a lower height

Otherwise: use a different type of pump

The suction pipe is clogged Clean

The pressure pipe is clogged Clean

There is a leak in the suction pipe Eliminate leak

Loading...

Loading...