BA series pumps

Pump unit with diesel drive 1401

8.20

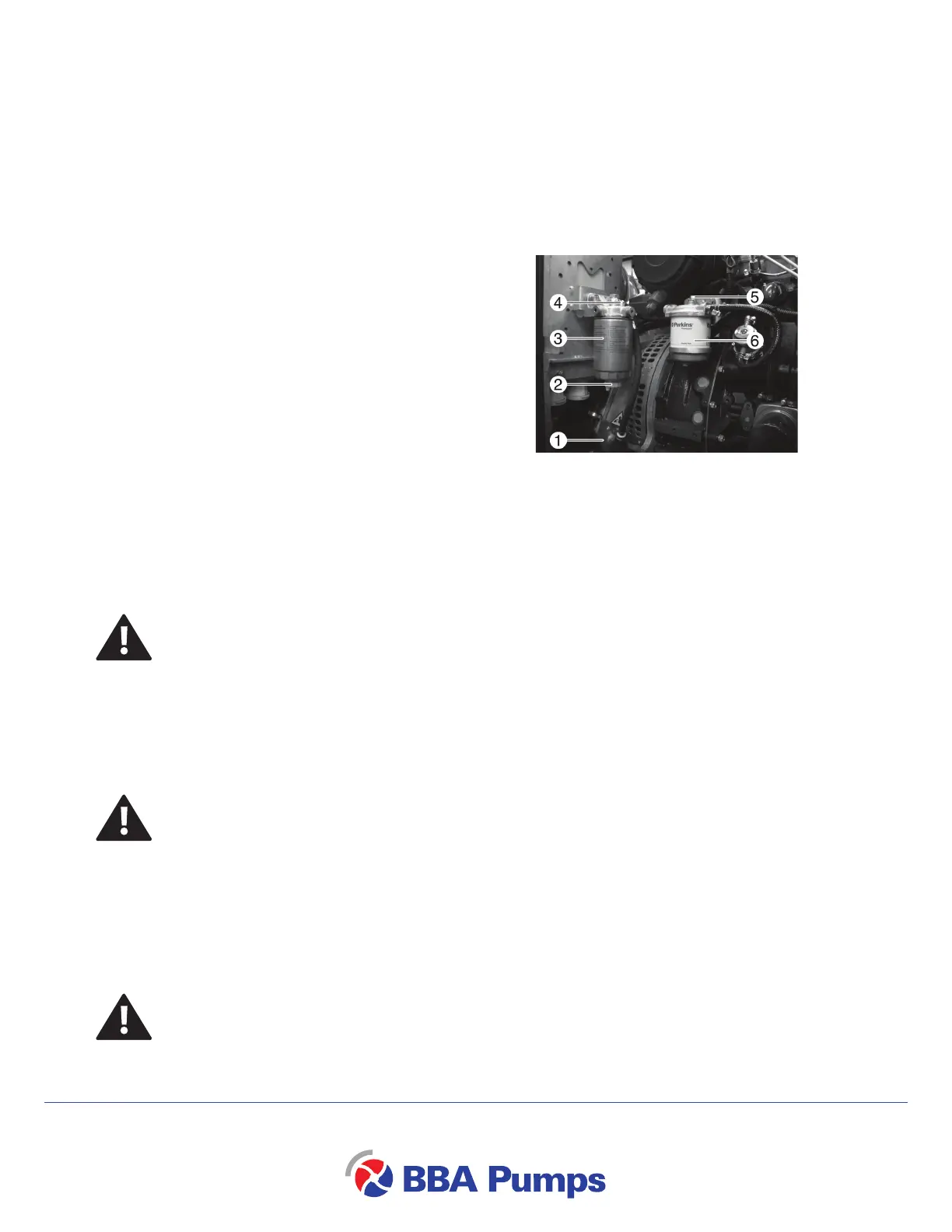

Checking the water trap

The intervals at which you should check the water trap depend entirely on the amount of water in the

fuel and the care taken when refuelling.

– Loosen the bottom of the water trap approx. 2-3

rotations.

– Trap the drops which emerge in a transparent (glass)

vessel.

Since water has a greater specific gravity than diesel

fuel, the water emerges before the diesel fuel. The two

substances separate at a clearly visible line.

– As soon as only diesel emerges from the opening, the

bottom of the water separator can be tightened again.

If an external water trap is attached, check its water

content every day, when the engine oil level is checked.

The water which has collected is separated at a clearly visible line from the diesel fuel above it.

Cleaning the cooling air system

WARNING

Before cleaning, the engine must be stopped and allowed to cool down.

–Remove parts of air duct.

Dry contamination

– Clean all air guide elements and the complete cooling air zones on the cylinder head, cylinder and

flywheel blades without making them wet. Blow them dry with compressed air.

WARNING

Persons handling compressed air must wear protective goggles.

Moist or oily contamination

– Disconnect the battery. Clean the complete area with a solvent, cold cleaner, etc. according to its

manufacturer’s instructions, then spray down with a powerful water jet.

Do not splash electrical devices with water jet or pressure jet during engine cleaning.

– Trace the cause of any contamination with oil and repair the leak (or have it repaired).

– Install the previously removed air guide elements.

WARNING

The engine must never be run without the air guide elements in position.

Loading...

Loading...