22

ENG

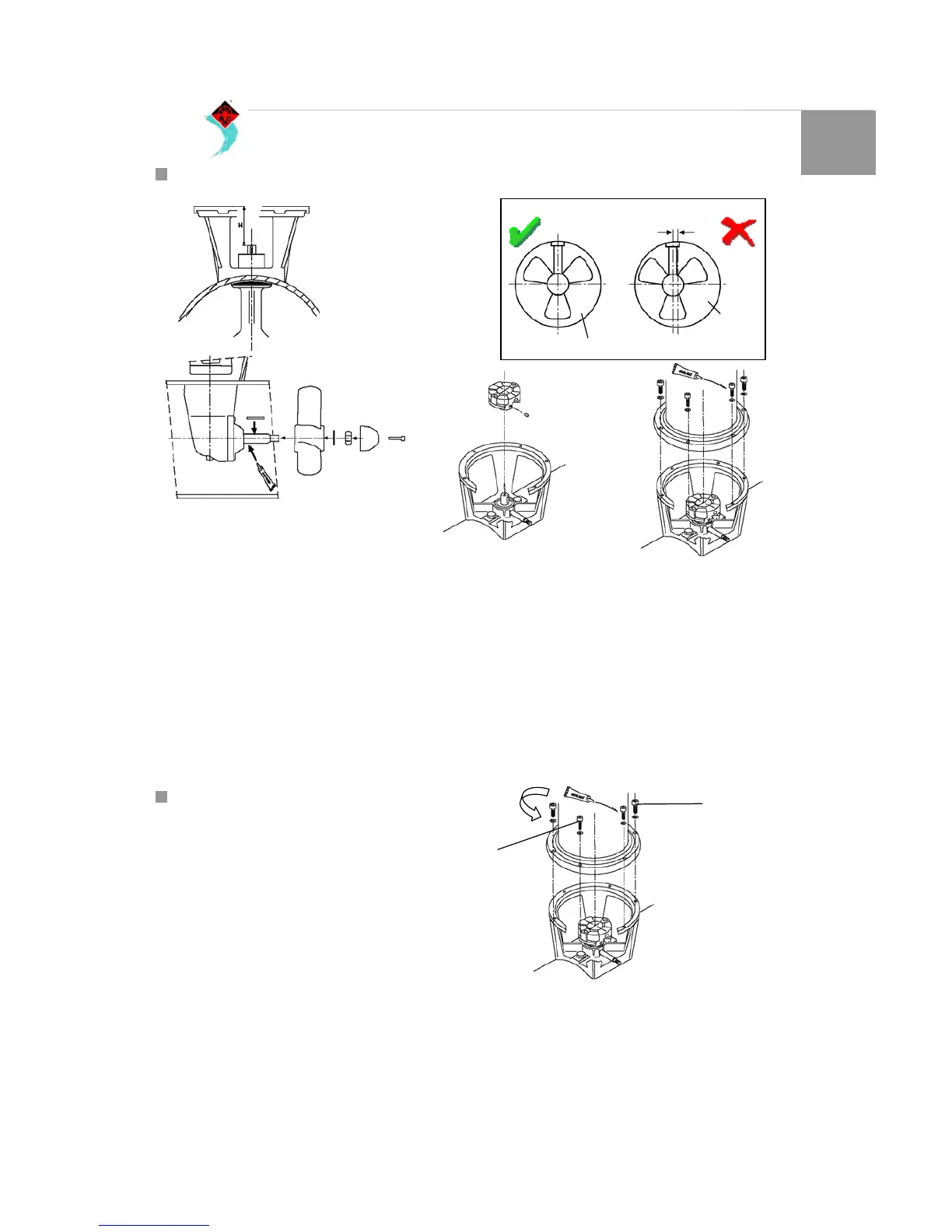

2.5 ASSEMBLING OF THE PROPELLER AND THE OIL RESERVOIR

Check again dimension `H`. (Fig. 26).

Make sure that the key is properly positioned in the key way of

the shaft. Grease the shaft with outboard gear grease and

install the propeller with the lock washer and the hexagonal

nut. Secure the nut by bending the tag of the washer. Fit the

zinc anode to the propeller shaft by means of the bolt. (Fig. 27)

The propeller should run a minimum of 1,5 mm free of the

thrust tube wall, all round (Fig. 28).

Grease the input shaft with an installation compound, like

Molykote ® G-n plus. Fit the flexible coupling to the input shaft

of the tail piece and sec ure the coupling with the locking screw.

Grease the shaft of the electric motor with an installation

compound, like Molykote ® G-n plus. Grease the threads of

the fastenings bolts with ‘outboard gear grease’ and install the

electric motor to the intermediate flange. Use one of these

bolts to fasten the relay support as well. For a first check, turn

the propeller by hand, it should turn easily, whilst being

connected to the output shaft of the electric motor (Fig. 29).

Assemble the oil reservoir over the water line level at a

height minimum of 500mm/ 20in. So that to ensure that there is

sufficient over pressure of oil in the tail piece. (Fig. 30). Ensure

that the tube does not form any air traps, which will restrict the

oil, to flow freely and that it has a correct angle that the oil

flows freely to the tail piece. Fill the reservoir with gear oil type

EP90.

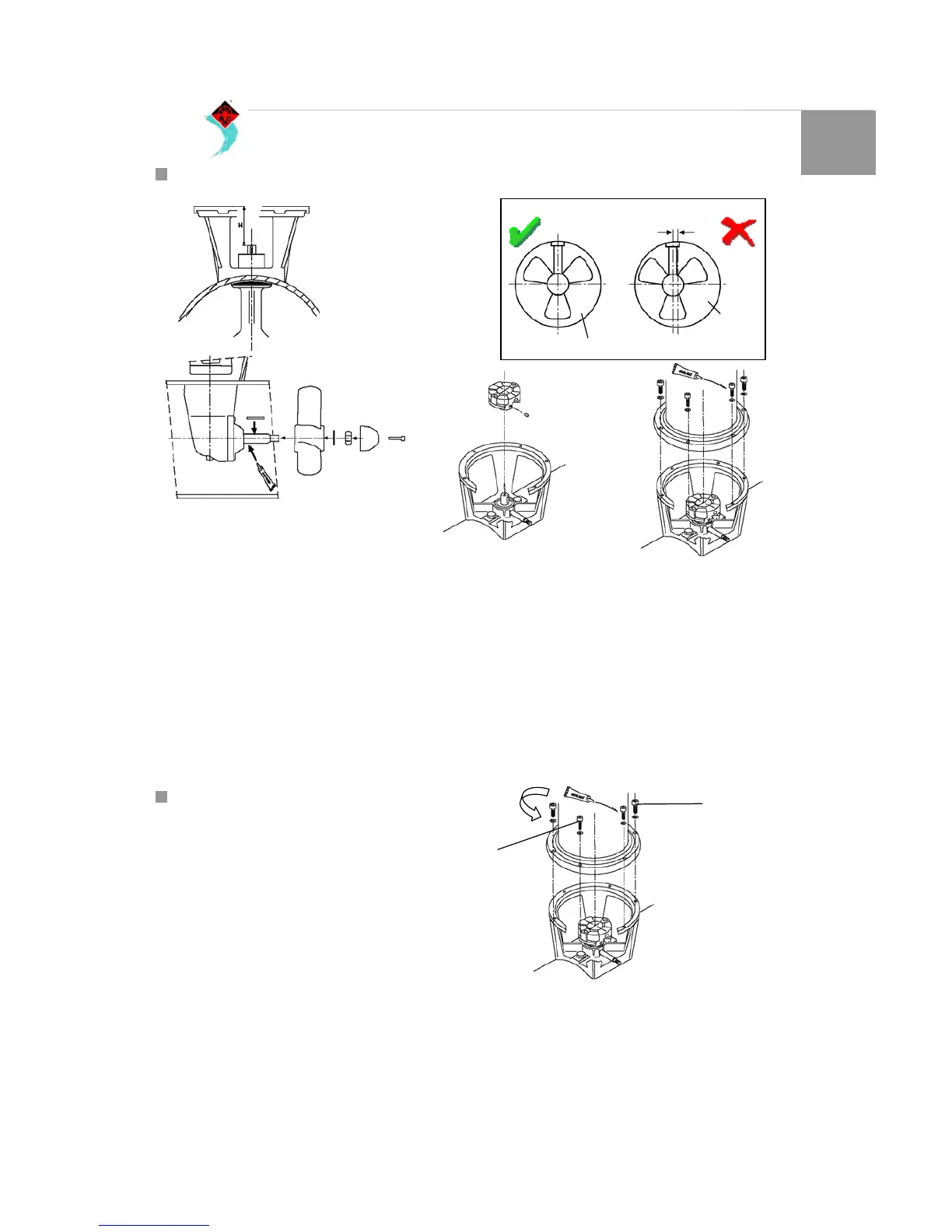

2.6 ASSEMBLING THE ELECTRIC MOTOR

Rotate the pilot shaft of the tail piece and rotate the shaft of the

motor in a way that the seating of the safety shear pin is in line

with that of the security pin on the shaft of the electric motor.

Slide slowly the electric motor on the pilot shaft and the motor

flange. It could be necessary to move it on either side to

inserted in, as could be slightly hard.

The electric motor could be positioned in any direction on the

flange. Verify that the cable terminals are available for the

following electrical installation.

Tight the screws for holding the electric motor (supplied) with a

torque of 17Nm /12.4lbft (Fig. 31).

As a first check, rot ate the propeller by hand, which has to

rotate freely, even though it is connected to the motor shaft.

Fig. 28

Tunnel

Distance

propeller/tunnel

Tunnel

Fig. 26

Fig. 27

Fig. 29

Fig. 30

Screws 17Nm/12.4lbft

Loading...

Loading...