1 695 301 979 2011-07-16| Beissbarth GmbH

Maintenance | MS 75 | 33MS 75 | 33 | 33 en

6. Maintenance

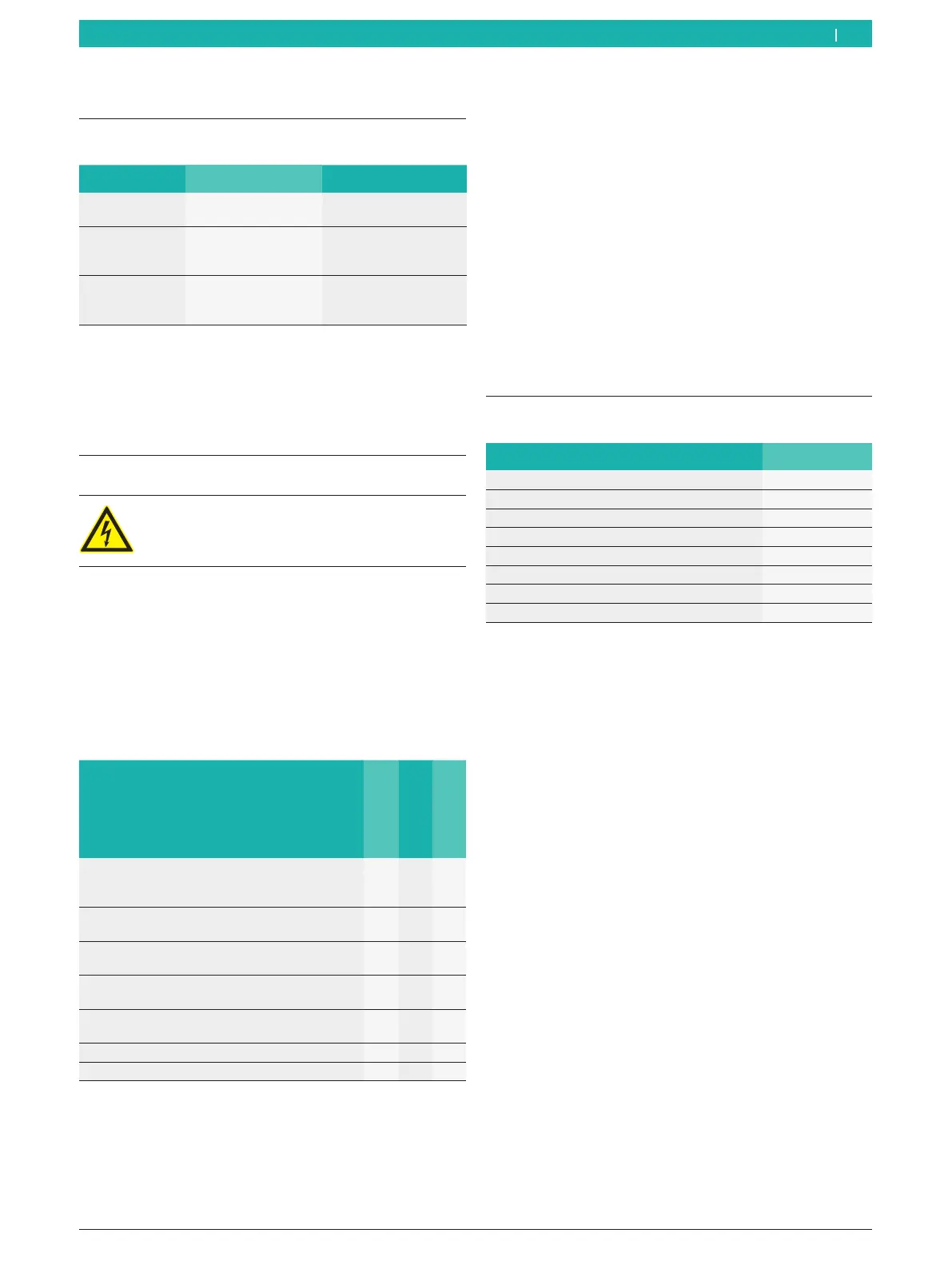

6.1 Suggested lubricants

Component Lubricant Standard

Gearbox ESSO Spartan EP460 ISO 460 DIN 51502-

CLP ISO 34-98-CC

Hydraulic pump ESSO NUTO H 46 ISO 46 DIN 51502-HLP

DIN 51524 PART.2-

HLP ISO 67-43-HM

Pneumatic sys-

tem (conditio-

ning assembly)

ESSO FEBIS K 32 ISO VG 32

Tab. 1: Lubricants table.

! The manufacturer is not liable for any damage

caused by use of lubricants different from those

shown in the table.

6.2 Cleaning and servicing

Before any cleaning or maintenance interven-

tion, disconnect the MS 75 by means of the

main switch and disconnect the network.

To guarantee full efficiency of the MS 75 and to ensure

functioning without anomalies it is essential to clean

the machine regularly and carry out periodical mainte-

nance.

Maintenance has to be carried out by the operator

in accordance with the manufacturer's prescriptions

shown here below.

6.2.1 Service intervals

Maintenance

weekly

monthly

annual

Clean the mechanical moving parts, spray

them with nebulized oil or kerosene and lubri-

cate with appropriate grease

x

Check transmission belt tensioning in order to

avoid its sliding.

x

Check the hydraulic control unit oil level and

keep it always between minimum and

x

Check and maintain the grease level on the

self-centering and on the tool holding arm.

x

Lubricate with grease the sliding rail of the

trolley.

x

Change the oil in the hydraulic control unit. x

Check the gearbox oil level. x

6.2.2 Check the hydraulic control unit oil level

1. Power off the equipment.

2. Unscrew the cap with measuring rod on the hydrau-

lic control unit.

3. Check that the oil level is between MIN and MAX.

6.2.3 Gearbox oil change

1. Put a collecting tank underneath the gearbox.

2. Unscrew the oil discharge screw.

3. Discharge the gearbox oil and dispose of it (see

chap. 7.3).

4. Screw the oil discharge screw.

5. Top up with new gearbox oil (see lubricant table).

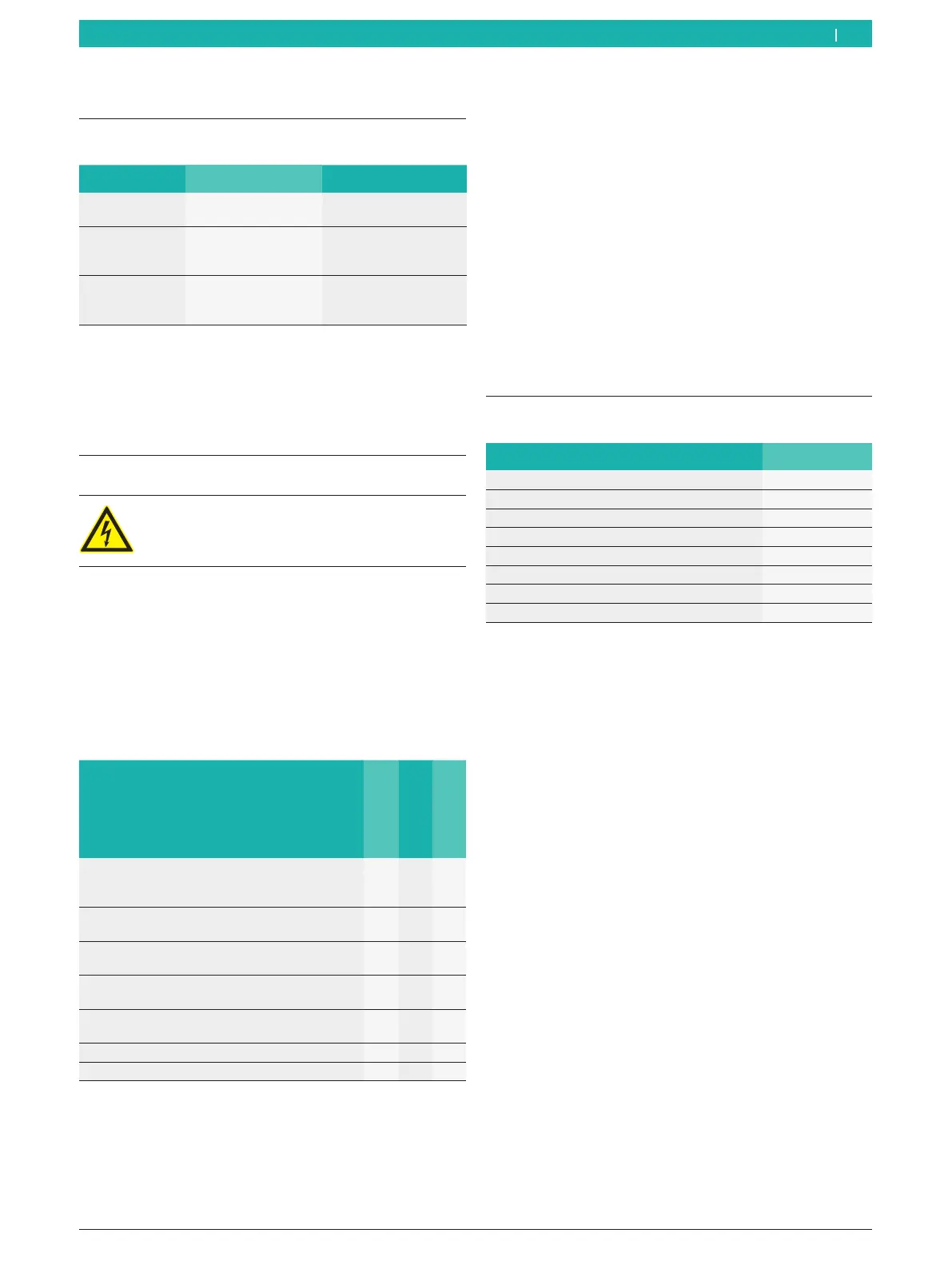

6.3 Spare and wearing parts

Denomination Order code

Rotary union

1 695 300 432

Anti-extrusion ring BR123

1 695 040 098

O-ring OR 123

1 695 040 093

Complete electrovalve 24V DC

1 695 042 413

Belt A33

1 695 042 198

4 position control lever

1 695 300 414

2 position switch

1 695 040 586

Nylon slider

1 695 300 232

Loading...

Loading...