38

2. Raise the Lift off of the Safety Locks by pressing the

push button on the Power Unit. Make sure you raise the

Lift by at least two inches to allow adequate clearance

for the locks to clear.

3. Press the push button air safety valve and HOLD.

4. Push the LOWERING HANDLE on the Power Unit

until the Lift has descended completely.

DAILY MAINTENANCE

1. Make a visual inspection of ALL MOVING PARTS and

check for excessive signs of wear.

2. Check safety locks to ensure they are in good operating

condition.

3. Check cables and sheaves for wear. Replace worn

parts as required with genuine BendPak parts.

4. Inspect adapters for damage or excessive wear. Re-

place as required with genuine BendPak parts.

5. Remove Slip Plates and inspect Ball Casters for Water,

Salt or Dirt and brush clean, then dry. Apply WD-40 or

equal to Ball Casters, if exposed to excess humidity,

water or ice.

WEEKLY MAINTENANCE

1. Lubricate all Sheave pins and rollers with general

purpose oil. (See page 42)

2. Check all Cable connections, bolts, and pins to

ensure proper mounting.

3. Lubricate Safety Lock pivot points with general

purpose oil or WD-40.

MONTHLY MAINTENANCE

1. Check Safety Locks to ensure they are in good

operating condition. Lubricate locking latch shafts.

Push release arm several times for oil to penetrate

pivot points.

2. Check equalizer cable tension. Adjust per Lift installa-

tion instructions.

3. Check all Cables for excessive signs of wear.

4. Make a visual inspection of ALL MOVING PARTS

and check for excessive signs of wear.

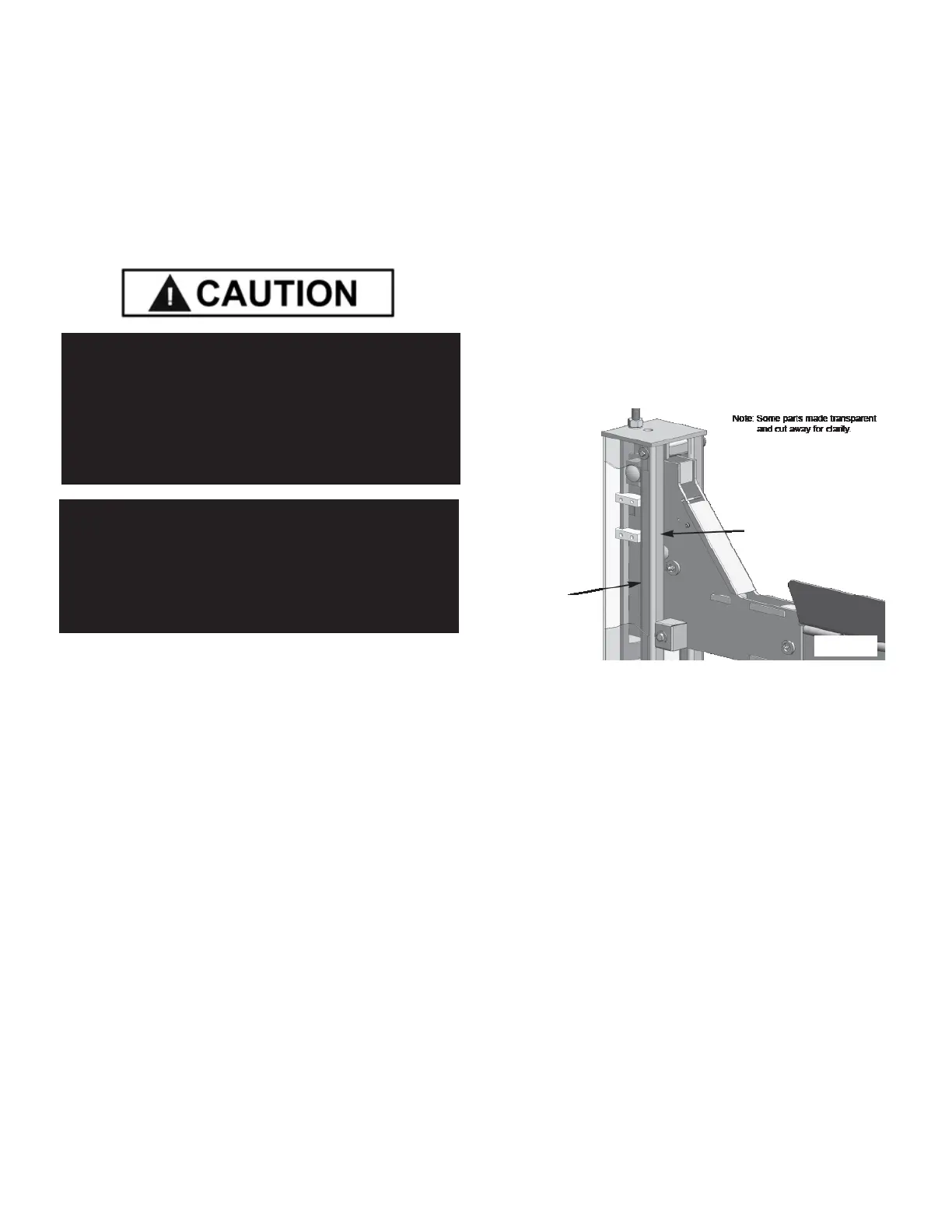

5. Lubricate both Open Front Post surfaces, on both

sides, with general purpose grease. (See Fig 19.1)

• Lubricate the slide blocks with general purpose grease.

Heavy usage may require more frequent lubrication.

• Always call local service representative if electrical

problems develop.

• Always replace ALL FAULTY PARTS before Lift is put

back into operation.

• Every 3 Months: Check anchor bolt torque. Anchors

should be torqued to 90 ft/lbs.

• Semi-Annually: Check fluid level of Lift power unit and

refill if required per Lift installation instructions.

• Replace all caution, warning or safety related decals

on the Lift if unable to read or missing. Reorder labels

from BendPak.

• Refer to ANSI/ALI ALOIM booklet for periodic

inspection checklist and maintenance log sheet.

IF YOU ARE NOT COMPLETELY FAMILIAR WITH

AUTOMOTIVE Lift MAINTENANCE PROCEDURES;

STOP AND CONTACT THE MANUFACTURER FOR

INSTRUCTIONS. UNLESS STATED OTHERWISE, ALL

MAINTENANCE CAN BE PERFORMED BY THE

OWNER/EMPLOYER AND DOES NOT REQUIRE

TRAINED Lift SERVICE PERSONNEL.

Lift OPERATION SAFETY (CONT’D)

Fig 19.1

BEFORE PERFORMING MAINTENANCE ON YOUR Lift,

MAKE SURE IT IS COMPLETELY DISCONNECTED FROM

POWER. IF YOUR ORGANIZATION HAS

LOCKOUT/TAGOUT POLICIES, IMPLEMENT THOSE

PROCEDURES AFTER CONNECTING TO THE POWER

SOURCE.

Loading...

Loading...