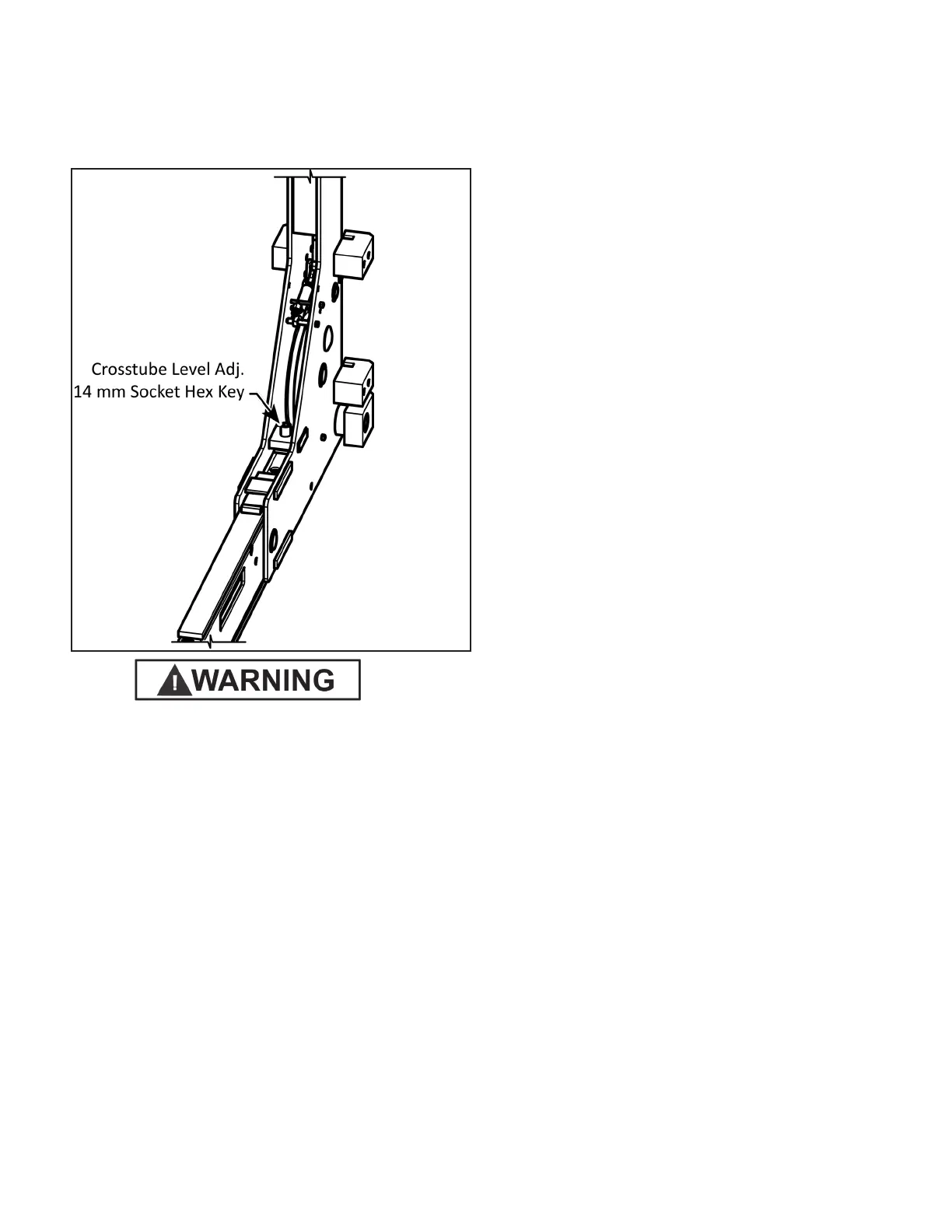

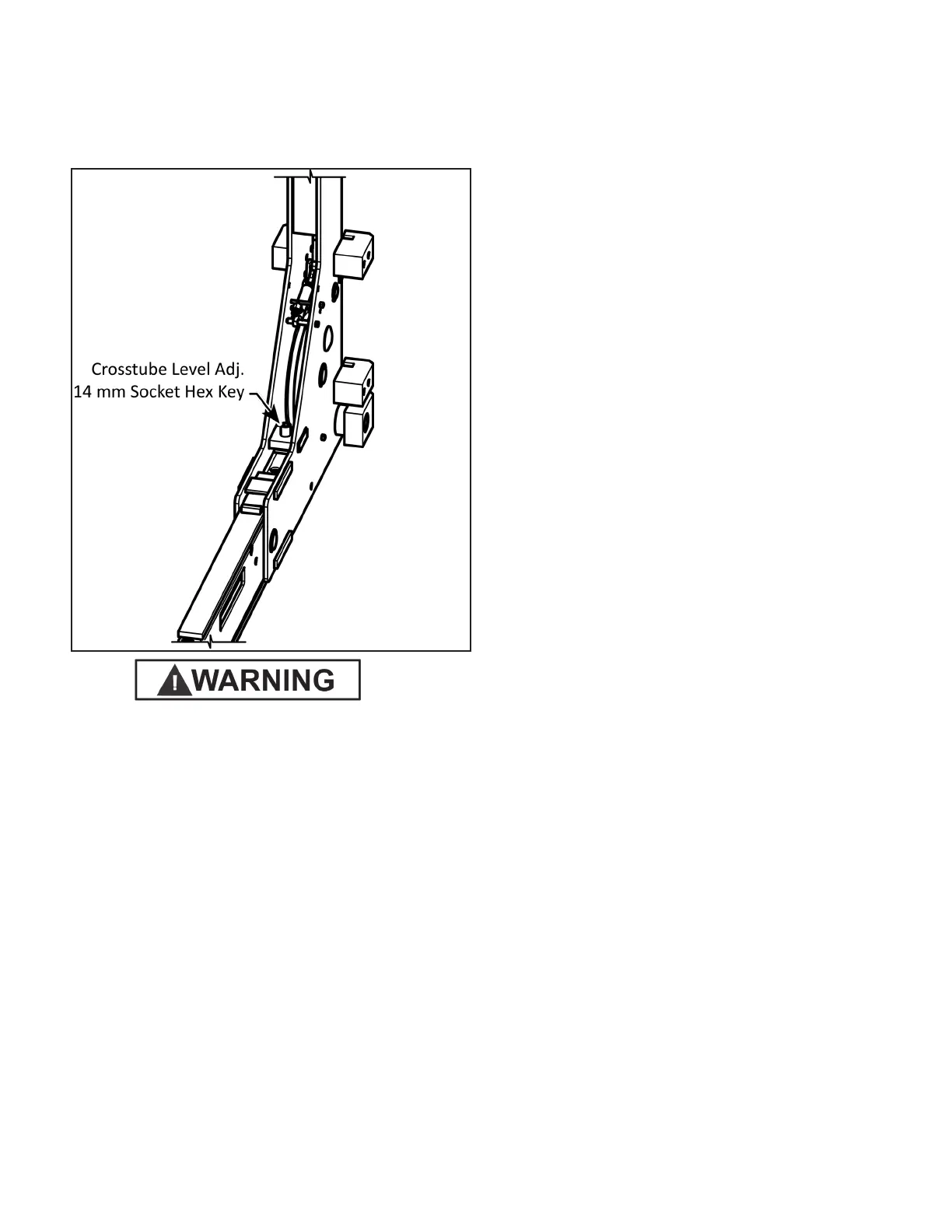

13. Remove the Vehicle from the Lift and using a level

adust both the Left and Right Short Crosstube until just

a slight upward angle is produced. This upward angle will

be corrected with Vehicle loading. A 14mm Hex Socket is

required to adjust the cap screw illustrated below Fig. 17.3.

Safety locks may not engage at exactly the same time

when Vehicles are being raised. They should be close. Be

sure that all four corners have passed the SAME safety

ladder bar slot before lowering Lift on the safety locks.

NEVER lower Lift on different safety lock position or dam-

age to the Lift may result.

STEP 18

(Bleeding)

1. Lift must be fully lowered before changing or adding fluid.

2. Raise and lower teh Lift six times. The Cylinder is

self-bleeding. After bleeding the system, fluid level in power

unit reservoir may be reduced. Add more fluid if necessary

to raise the Lift to its full height.

3. To pressure test, run Lift to full rise and run Motor

for approximately 3-seconds after the Lift stops. This will

place pressure on the hydraulic system. Stop and check all

fittings and hose connections. Tighten or reseal if required.

STEP 19

(APPLY ANTI-SLIP TAPE)

1. Clean the runway. Use a broom or brush to remove

loose dirt and debris from the runway.

2. Thoroughly wash, rinse and dry the runway using a

mild solution of soap and clean water to remove any oils,

grease and water-solubleClean contamination. Dry the

runway with a clean cloth and allow to air dry.

3. Cut the Anti-Slip Tape into four equal pieces.

Suggested length is 72 in. (1,829 mm).

4. Verify the Runway is dry and clean. It is critical for

maximum adhesion of the Anti-Slip Tape that the runway

be dry, free of dirt, oils and grease.

5. Measure and mark the runways with pencil guide lines

to outline the tape installation area on the ramp. Refer to

the figure on the next page for a suggested layout of the

Anti-Slip Tape.

IMPORTANT! Do not install this Tape directly on the

edge of a Runway. Stay at least 1 in (25 mm) away from

edges. Do not attempt to bend this Tape over an edge.

6. Wash your hands. The Anti-Slip Tape’s adhesive side

is protected by a paper or plastic film. You will remove

this film a few inches at a time to apply the Tape to the

Runway.

IMPORTANT! Handle the tape by its edges. Minimize

contact between the adhesive and your hands. The oils

from your hands will reduce the adhesive’s long-term

effectiveness.

IMPORTANT! BendPak recommends two people work

together to install the Tape. One person removes the

backing and applies the Tape to the Runway while the

second holds the Tape in place over the guide lines

marked on the Runway.

7. Lay one piece of the Anti-Slip Tape on the runway and

peel back about 2 inches (50 mm) of the protective film.

Apply the adhesive side to the Runway inside the guide

lines you created in step 5.

8. Slowly remove the film as you press the exposed

Tape’s adhesive side into the Runway. Work slowly and

apply 2 to 5 inches at a time to stay within your guide

lines.

9. After applying the Tape use a heavy rubber roller

to press the Tape into the Runway and to ensure firm

contact with the adhesive.

10. Apply the Anti-Slip Tape to the remaining area of the

Lift’s runways similar to the figure below.

31

Fig. 17.2

Loading...

Loading...