CARRIAGE SENSOR TEST (X13,

X13A)

Certain procedures in this section require

electrical test or measurements while power is

applied to the machine. Exercise extreme caution

at all times. If test points are not easily accessible,

disconnect power and follow lockout / tagout

procedures, attach test equipment and reapply

power to the test.

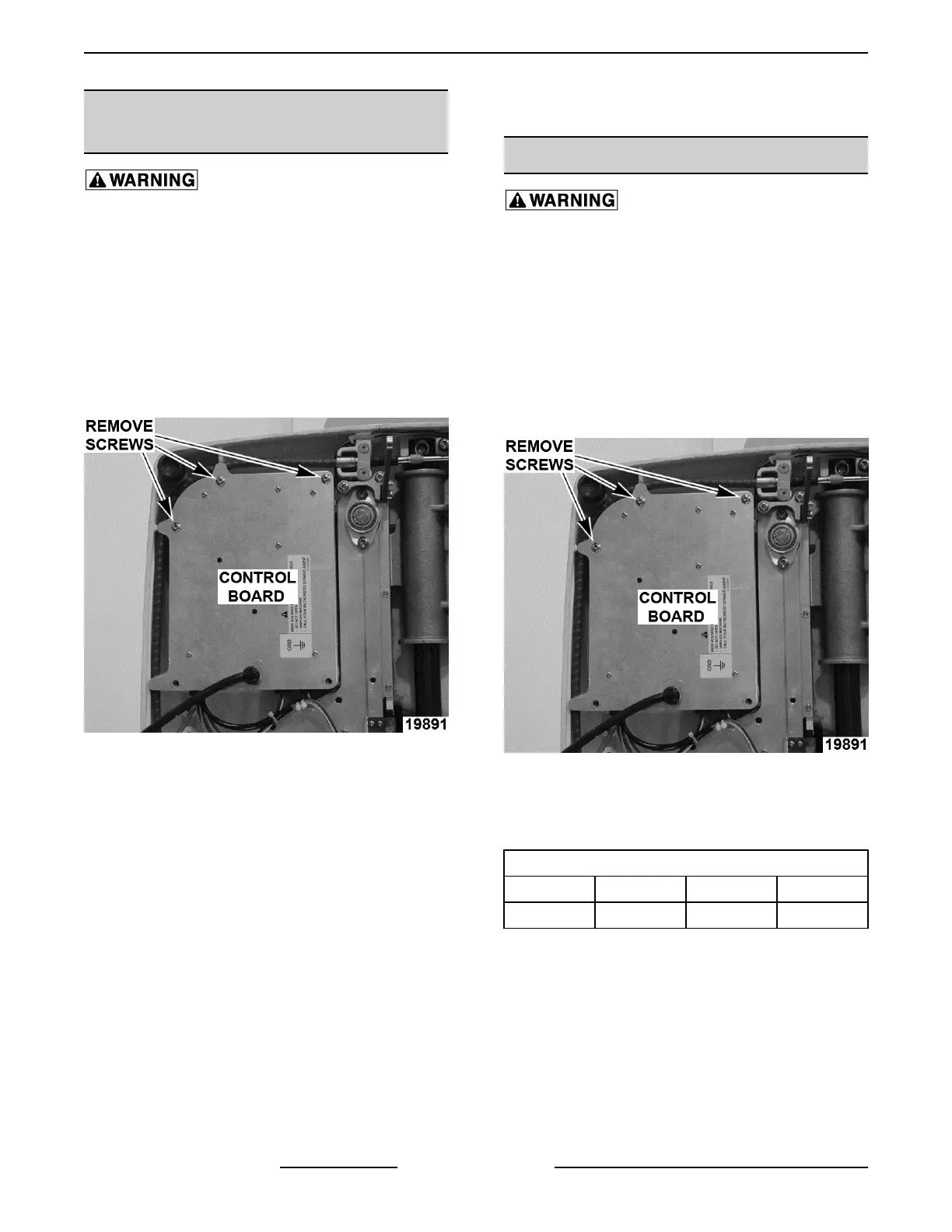

1. Place slicer on its side, so it is resting on motor

housing.

2. Remove screws to access control board.

Fig. 82

3. Plug slicer in.

4. Verify 5VDC supply voltage between J4-1 and

J4-5.

A. If voltage is not present, check all

connections.

B. If connections are good, replace control

board.

5. Verify 0VDC between J4-2 and J4-5 in manual

mode (clutch engage rod in).

6. Verify 5VDC between J4-2 and J4-5 in auto mode

(clutch engage rod out).

7. Verify 5VDC between J4-3 and J4-5 when arm

assembly is in home position.

A. 0VDC should be present anytime arm

assembly is away from home position.

8. If voltages are not all present, replace carriage

sensor.

KNIFE MOTOR OHM TEST

Certain procedures in this section require

electrical test or measurements while power is

applied to the machine. Exercise extreme caution

at all times. If test points are not easily accessible,

disconnect power and follow lockout / tagout

procedures, attach test equipment and reapply

power to the test.

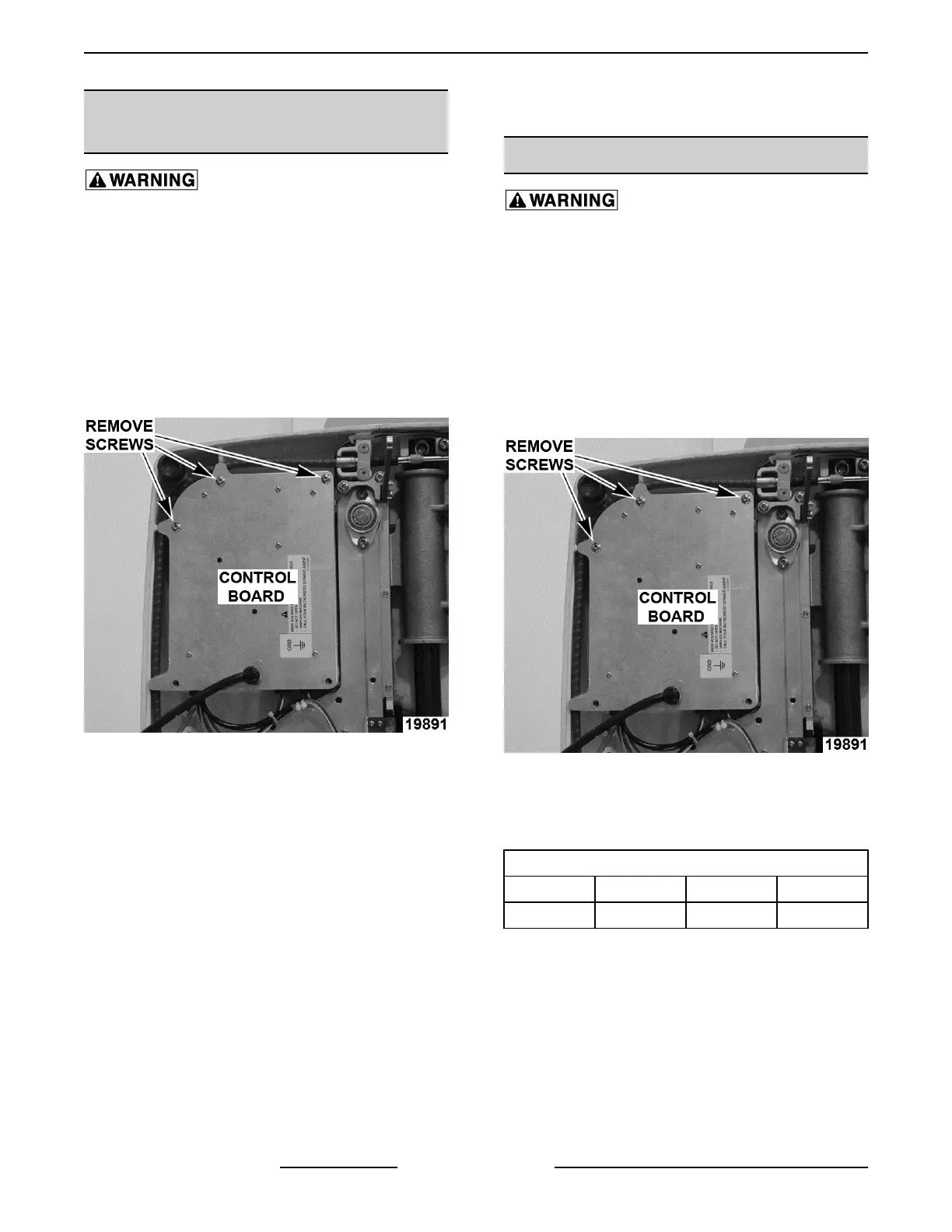

1. Place slicer on its side, so it is resting on motor

housing.

2. Remove screws to access control board.

Fig. 83

3. Connect a volt/ohm meter to both disconnected

motor lead wires (P1 and P2) and verify ohm

readings per chart.

MOTOR RESISTANCE

Volts Hertz Min. Max.

115 60 1.21 1.33

4. If ohm readings are out of spec, replace motor.

X13 SLICER - SERVICE PROCEDURES AND ADJUSTMENTS

F25332 Rev. A (0718) Page 30 of 36

Loading...

Loading...