3.5 Grinding stone dressing

A diamond dresser is supplied, tted to the grinding head.

The grinding stone should be dressed periodically, by

adjusting the dresser towards the stone with the secondary

control knob that draws the dresser onto the stone. Then rotate

the control knob back and forth making a few light passes of

the dresser, to ensure that the stone does not become “loaded”

(clogged). New stones should ALWAYS be dressed!

There is no necessity to alter the set up to do this. The cut

can simply be taken off with the single point feed handwheel

and the stone can be dressed mid way through a grind, if

necessary.

Ensure that adequate eye / breathing protection is used.

3. Setting Up (Continued)

3.6 Grinding stone replacement

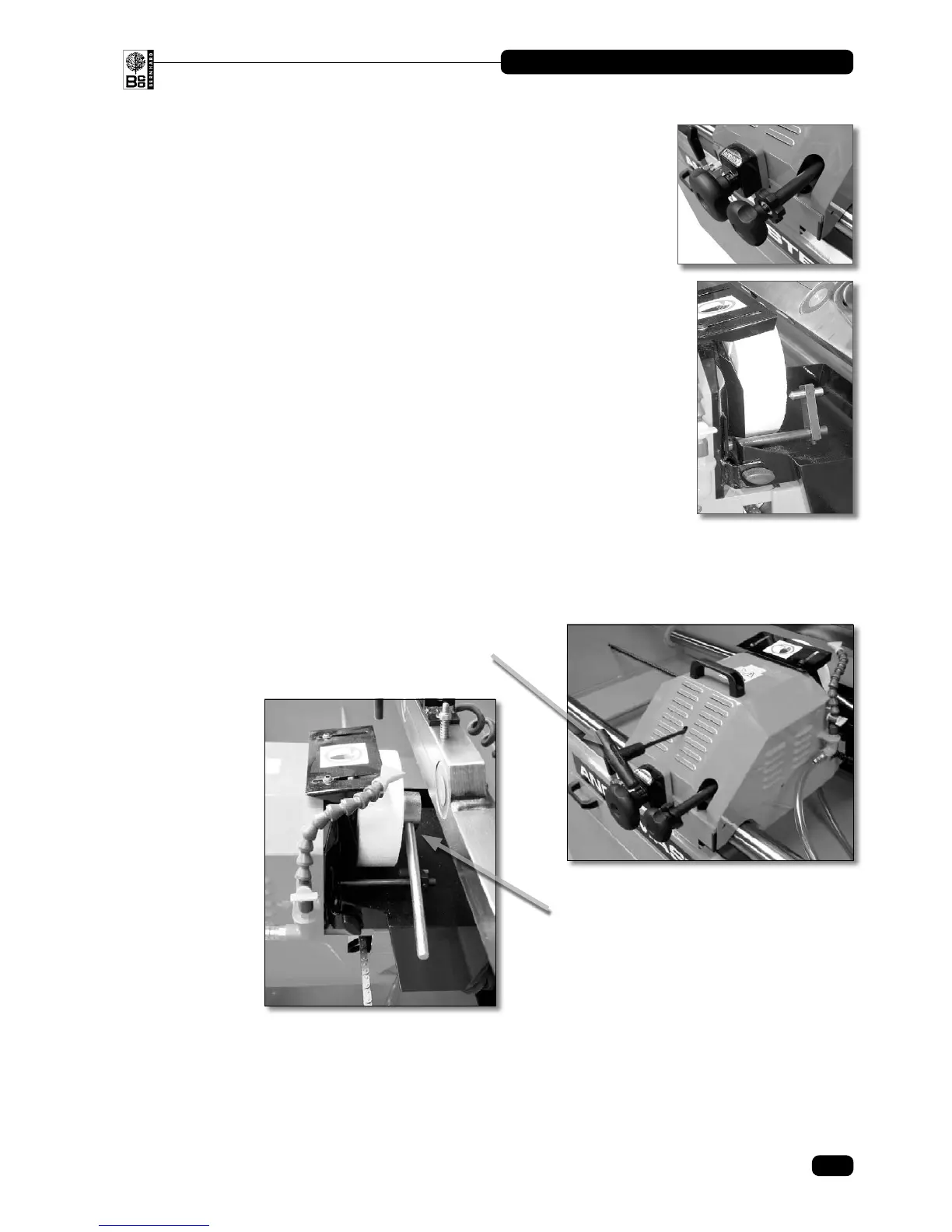

Isolate the electrical supply. Rotate the mounting bar so that the top face (magnets) face

the operator. Wind the grinding head back to it’s rear-most position (nearest the operator)

Insert a 6mm hex key into the socket at the rear of the motor and undo the grindstone nut

with the box spanner provided.

Before tting a replacement stone, the new stone should be carefully examined for

damage. It should be held loosely and “rung” by tapping gently with a non-metallic object

such as a screwdriver handle. A sound stone will make a clear ringing noise. Reject a

stone that sounds “dead”. Ensure that there is no loose grit/debris between the stone and

the mounting anges.

Box spanner

Key

12

ANGLEMASTER • AM3000

© Bernhard and Company Limited

Loading...

Loading...