BestCode Next Series 8 Technical Manual October 2022 Page 209 of 290

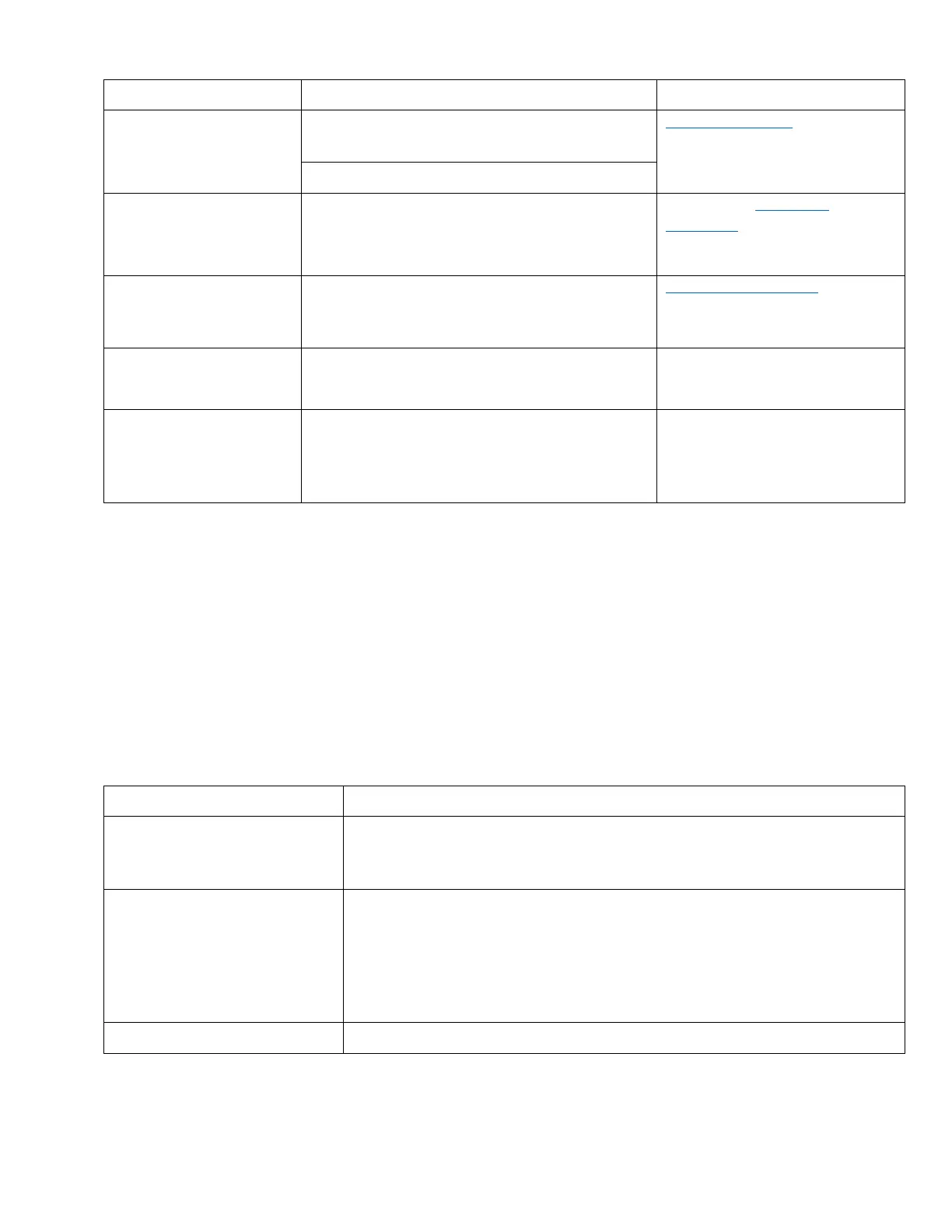

Bearding Causes

Incorrect Printhead Setup

Head too close to the product causing static

reflection of drops into the printhead

Poor print angle allow splash back into the printhead.

Bad modulation range or window.

Verify correct Modulation

Calibration.

When the jet clips the inside or outside edge of the

gutter, splashing can occur in the head resulting the

bearding.

Too much ink on the substrate can cause a pool of

ink to dwell and encourages splashing

Increase width/reduce boldness

Increase print height.

Ink droplets are electrically charged, an electrically

charged conveyor (poor grounding, static, voltage

drain, etc) can cause ink drops to be repelled back

towards the printer head.

Use BestCode’s Positive AirFlow™

pump or -DRY kit for printer.

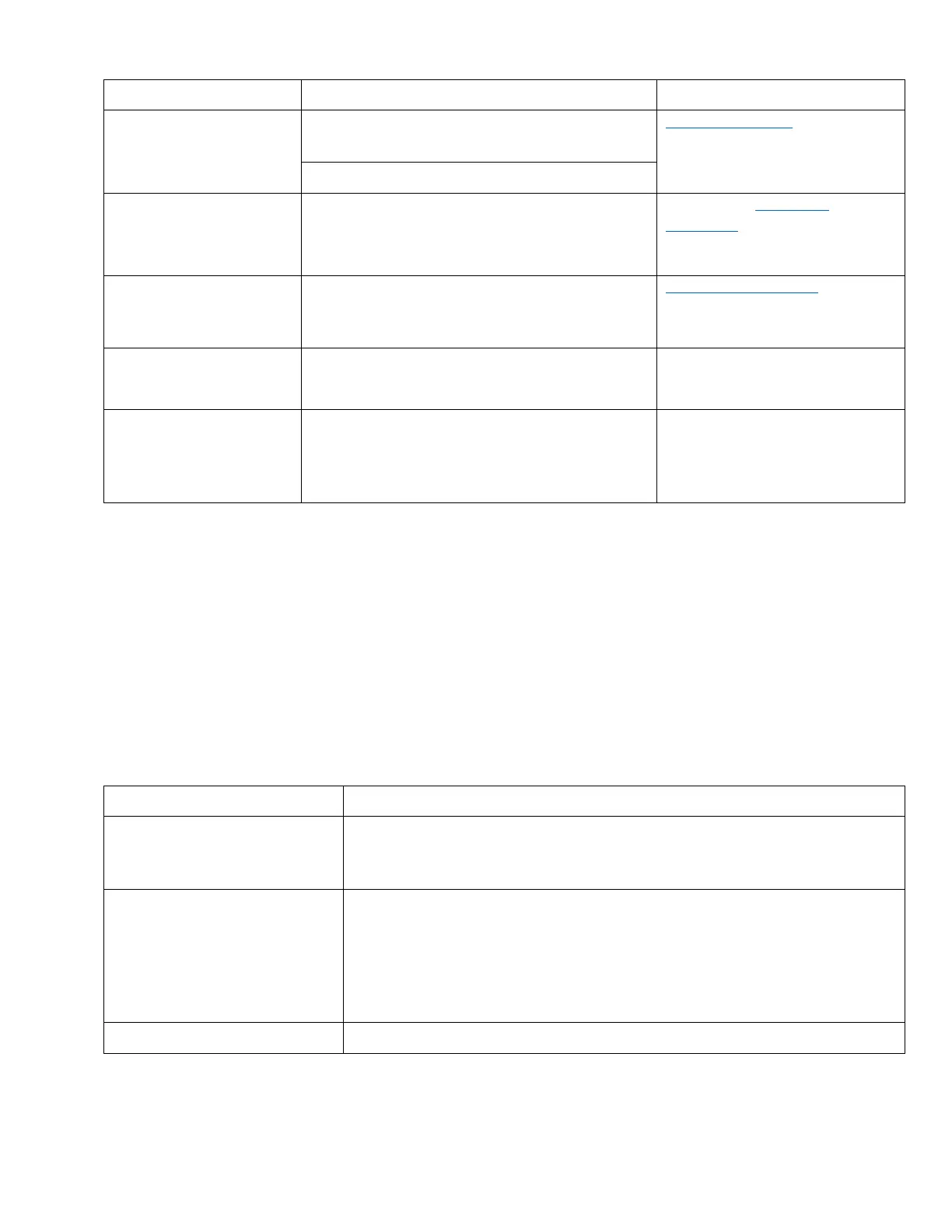

Messy Starts and Stops

• During the flush start / flush stop routine, the jet deviates and spills either onto the printhead or out of the head

onto conveyors or floor.

• A poor Flush Stop will not adequately clean the head and will then cause a poor start at next jet start.

• Often requires manual cleaning to resolve, but issue still persists.

Messy Starts and Stops Causes

• A number of issues can cause poor starts and stops, some simple, other more complex

This will cause poor starts and stops. The flush routines run at lower pressures

intended for jetting Makeup. If the Makeup tank is empty, the system will be flushing

with Ink and cause a mess.

Having a weak Venturi will not allow Makeup to be adequately drawn through the

system. Lines will be left full of ink, and the flush routines will perform poorly since

they are intended to run with clean Makeup.

Venturi Testing Instructions are here.

Nozzle / Drop Generator Clog

Either a clog in the nozzle or in the Venturi can cause

Loading...

Loading...