CB-S / CB-S-UL (E7) 06/2020 page 86/119

We recommend regular disinfection of the CO

2

sensor.

Danger of damage to the CO

2

sensor when connecting or removing it during opera-

tion.

Damage to the CO

2

sensor.

Connect or remove the CO

2

sensor only with the chamber turned off.

Recommended procedure:

• Turn off the chamber

• Pull out the sensor

• Spray the sensor head with alcohol or wipe it clean with a soaked cloth. Observe the reaction time of

the disinfectant used.

• Before reinserting the CO

2

sensor, it must be completely dry.

• The filter in the front of the sensor only needs replacing when damaged or dirty.

The CO

2

sensor head was especially adjusted for the specific chamber. To avoid confusion, an adhesive

label with a serial number is adhered to the sensor head. When exchanging the sensor, repeat CO

2

ad-

justment.

Danger of confusing CO

2

sensors.

Invalid calibration.

Do NOT change the CO

2

sensor head.

Note down the serial number of the CO

2

sensor.

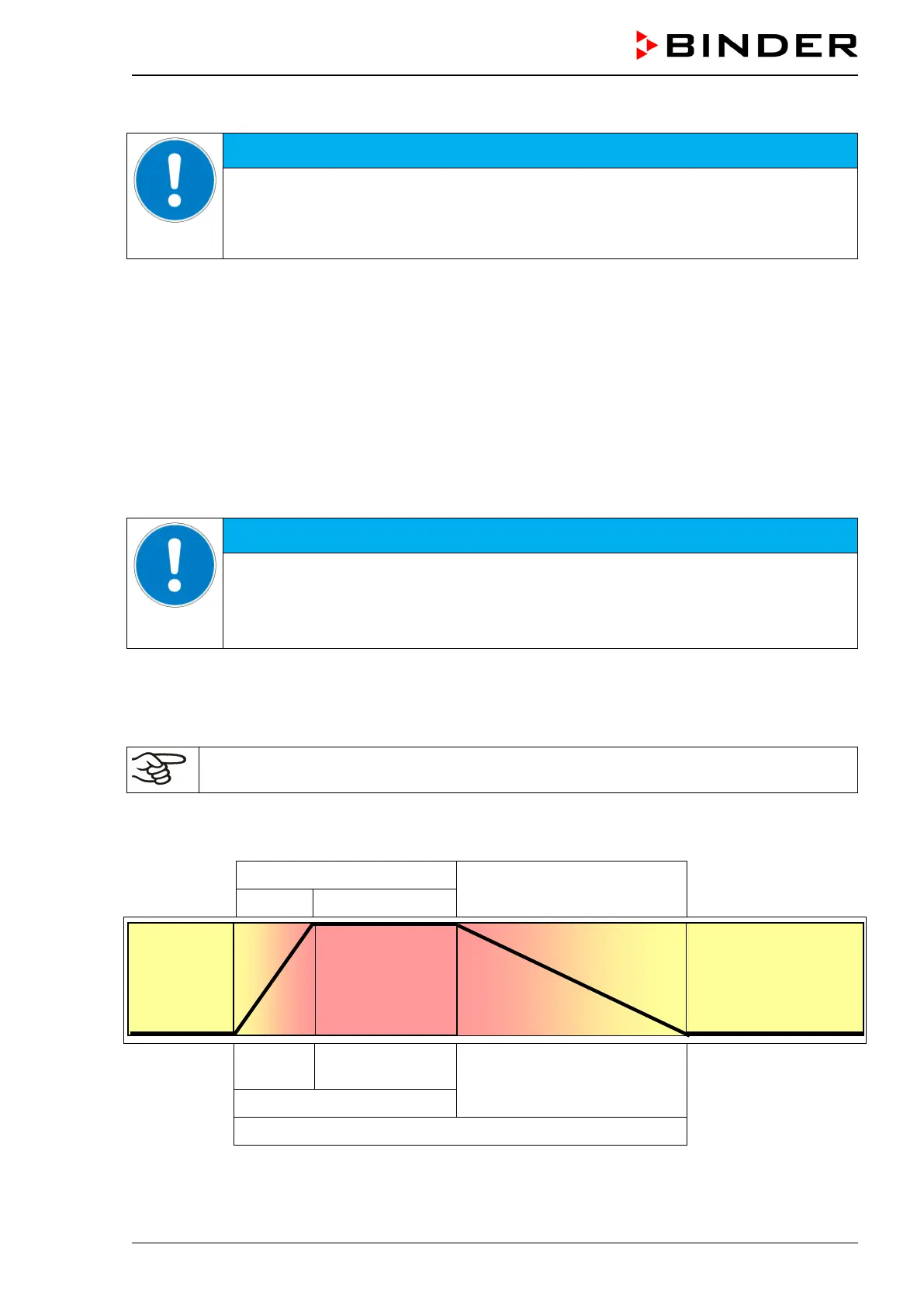

23. Hot-air sterilization at 180 °C / 356 °F

The very first sterilization after operation may cause an odor. This is not a quality defect. We

recommend ventilating well the room during sterilization.

23.1 Overview

Effective sterilization

Cooling down

Heating up

Holding

approx. 2

hours

4 hours

approx. 6 hours

6 hours

Sterilization cycle: Total duration approx. 12 hours

Figure 21: Temperature set-point profile and phases of the sterilization cycle

Loading...

Loading...