DB-300-9 27

5 Commissioning

The pressure equipment was tested in the factory as a

single unit. After installation, the tightness of the con-

nections and of the piping system must be tested

again.

5.1 Charging with oil

OA1854(A) .. OA25012(A), OA1954(A) .. OA25112(A)

Fill the entire oil charge of the system at the oil fill con-

nection of the oil separator.

Oil quantity:

• operating charge of the oil separator

• plus the entire oil quantity circulating in the system

(e.g. oil cooler, oil line)

OAS322 .. OAS3088, OAF6288 .. OAF15211

Prefill oil operating charge in secondary oil separator

(OAHC: in tertiary oil separator).

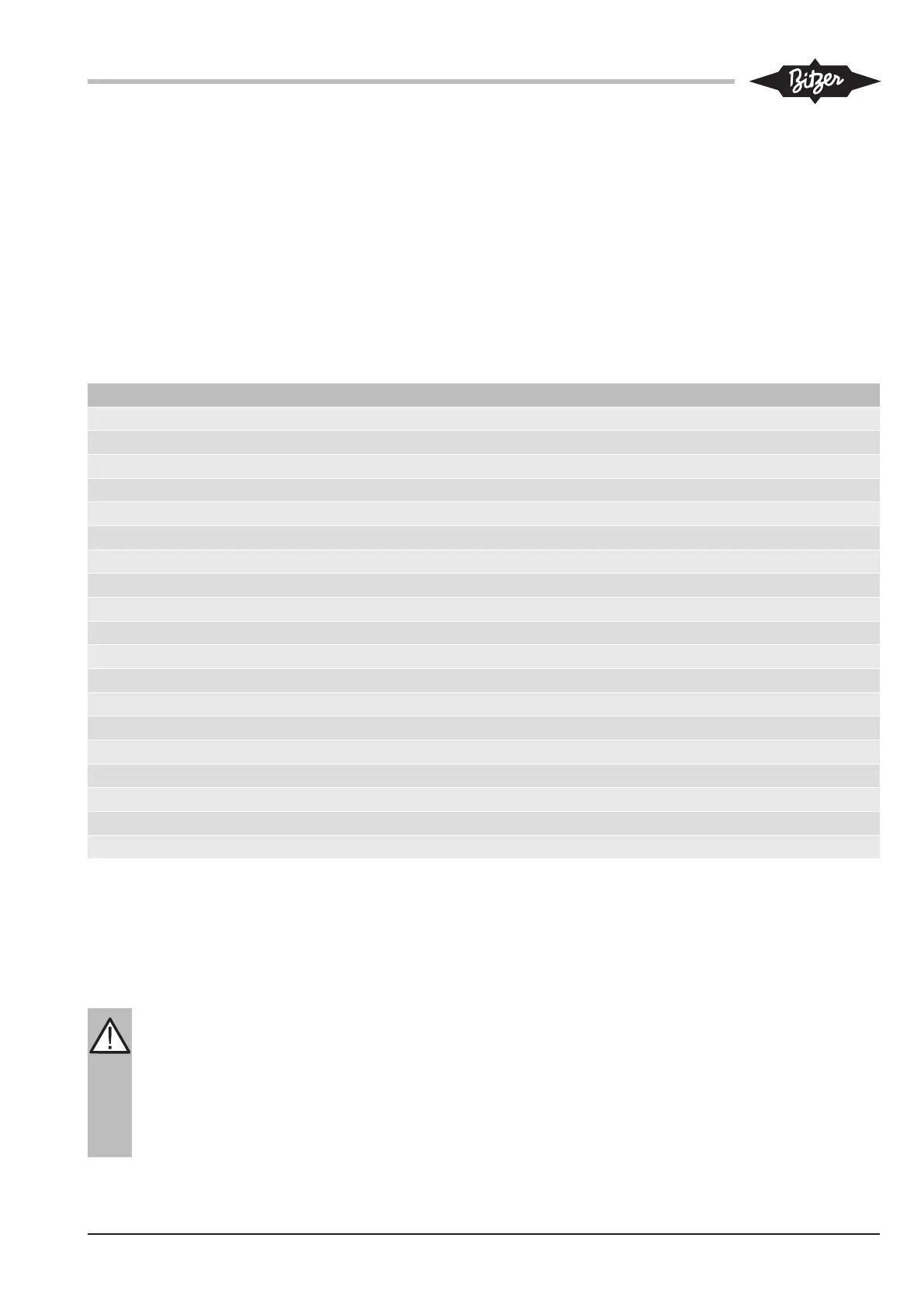

Type Operating charge

OA1954(A) 18 l

OA4188(A) 40 l

OA9111(A) 90 l

OA14111(A) 140 l

OA25112(A) 250 l

OAC14011A 140 l

OAC25112A 250 l

OAH2888 28 l

OAH7088 70 l

OAS322 approx. 0.5 l

OAS744 approx. 1.0 l

OAS1055 approx. 1.0 l

OAS1655 approx. 1.0 l

OAS3088 approx. 1.5 l

OAF6288 11.8 l

OAF15211 31.8 l

OAHC65051A 80 l

OAHC80051A 180 l

OAHC100051A 310 l

5.2 Checking tightness

Check the refrigerant circuit (assembly) for tightness,

as a whole or in parts, according to EN378-2 (or other

applicable equivalent safety standards). For this, create

an overpressure, preferably using dried nitrogen.

DANGER

Risk of bursting due to excessive pressure!

The pressure applied during the test must never

exceed the maximum permitted values!

Test pressure: 1.1-fold of the maximum allow-

able pressure (see name plate). Make a distinc-

tion between the high-pressure and low-pres-

sure sides!

5.3 Evacuation

• Switch on the oil heater.

• Open all shut-off valves and solenoid valves.

• Use a vacuum pump to evacuate the entire system,

including the compressor, on the suction side and

the high pressure side.

With the vacuum pump shut off, a "standing vacuum"

lower than 1.5mbar must be achieved.

• Repeat the operation several times if necessary.

Loading...

Loading...