OZONE ANALYZER BMT 965 Manual, Rev. 01/2024

___________________________________________________________________________

56

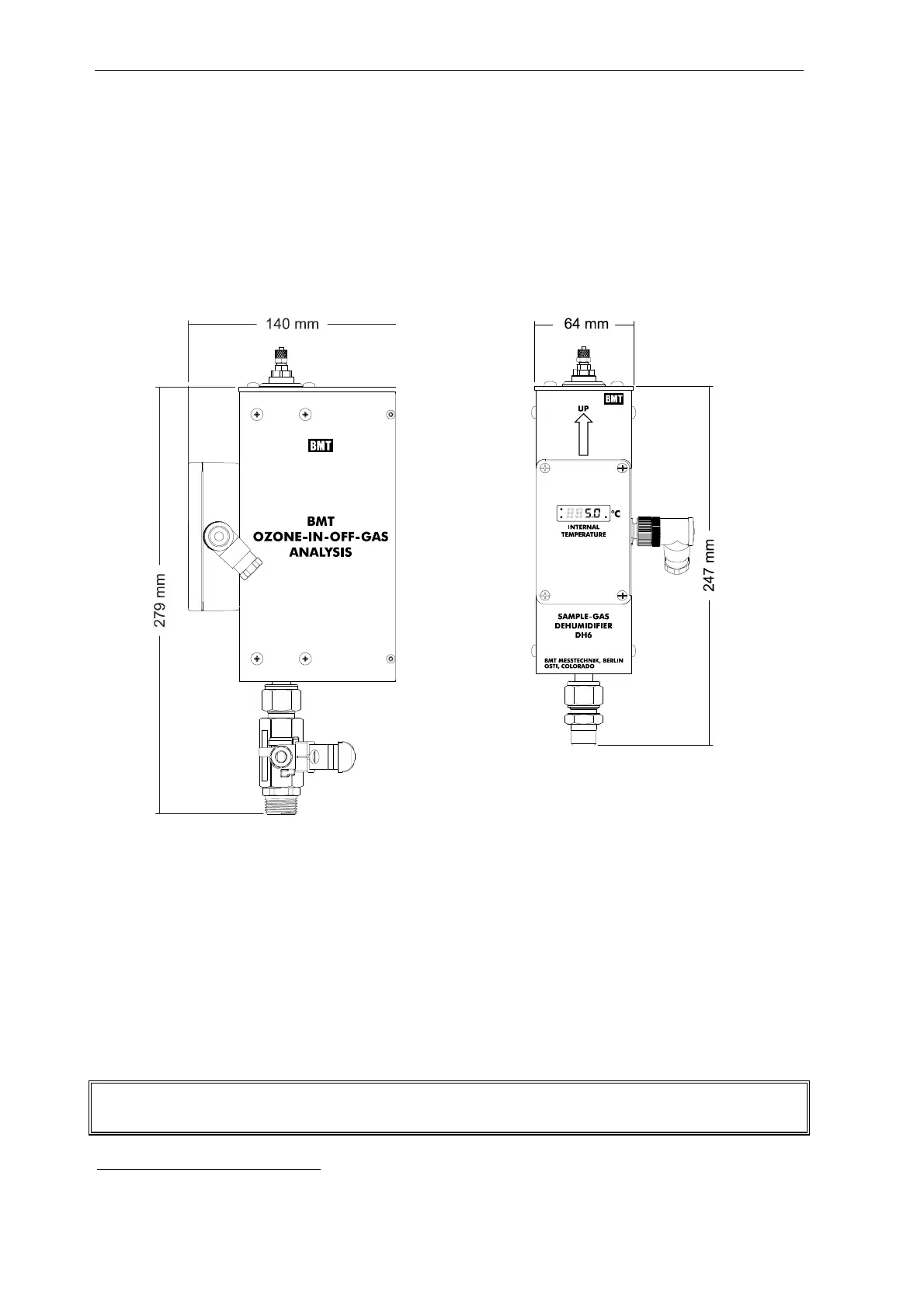

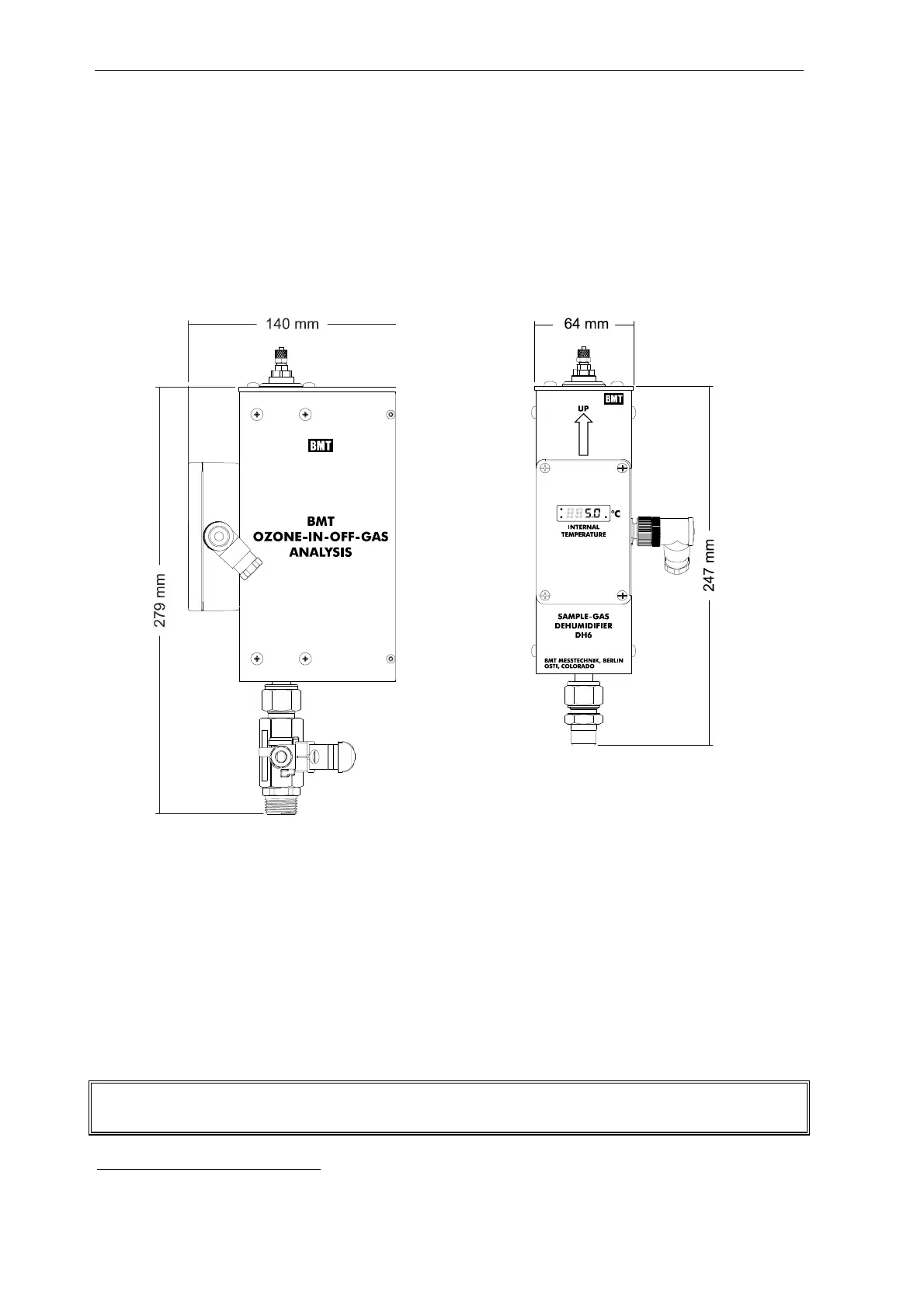

The dryer has to be mounted standing upright

2

on one "leg" on top of the reaction vessel, or large

diameter off-gas tube.

In case the off-gas is at atmospheric pressure, the "leg" is plugged into an ID 12 mm SS fitting with

a PTFE seal. The fitting can be screwed into a 3/8'' NPT threaded bore hole, or it can be welded

directly into a bore hole 17 mm ID. A PVC plug 12 mm OD is permanently linked to the mounting

fitting by a thin SS stranded wire, to tightly close the fitting when the dryer has to be removed for

service or repair.

DH6 with SOBV (shut-off ball valve) DH6

If the off-gas is at an overpressure, or at a slight vacuum, the DH6 should be mounted via a ball

valve. The ball valve is screwed into the reactor vessel in a 1/2" NPT threaded bore hole. Welding

the ball valve is not recommended.

The DH6 electric cooler/dryer and the analyser cabinet BMT 965 OG are connected by an electric

cable, and two FEP tubings 3x5 mm leading the sample gas from the reactor to the analyser for

ozone measurement, and leading it back to the reactor after measurement (no critical ozone de-

struct necessary). The maximum length of the electrical connection between the cabinet and the

cooler/dryer is 10 m.

Warning: Before opening the sample gas filter make sure that the sample line does not contain

ozone gas, and is not under an overpressure.

2

The DH6 must necessarily stand upright because the condensate formed inside the cooler has to flow back into the

off-gas system.

Loading...

Loading...