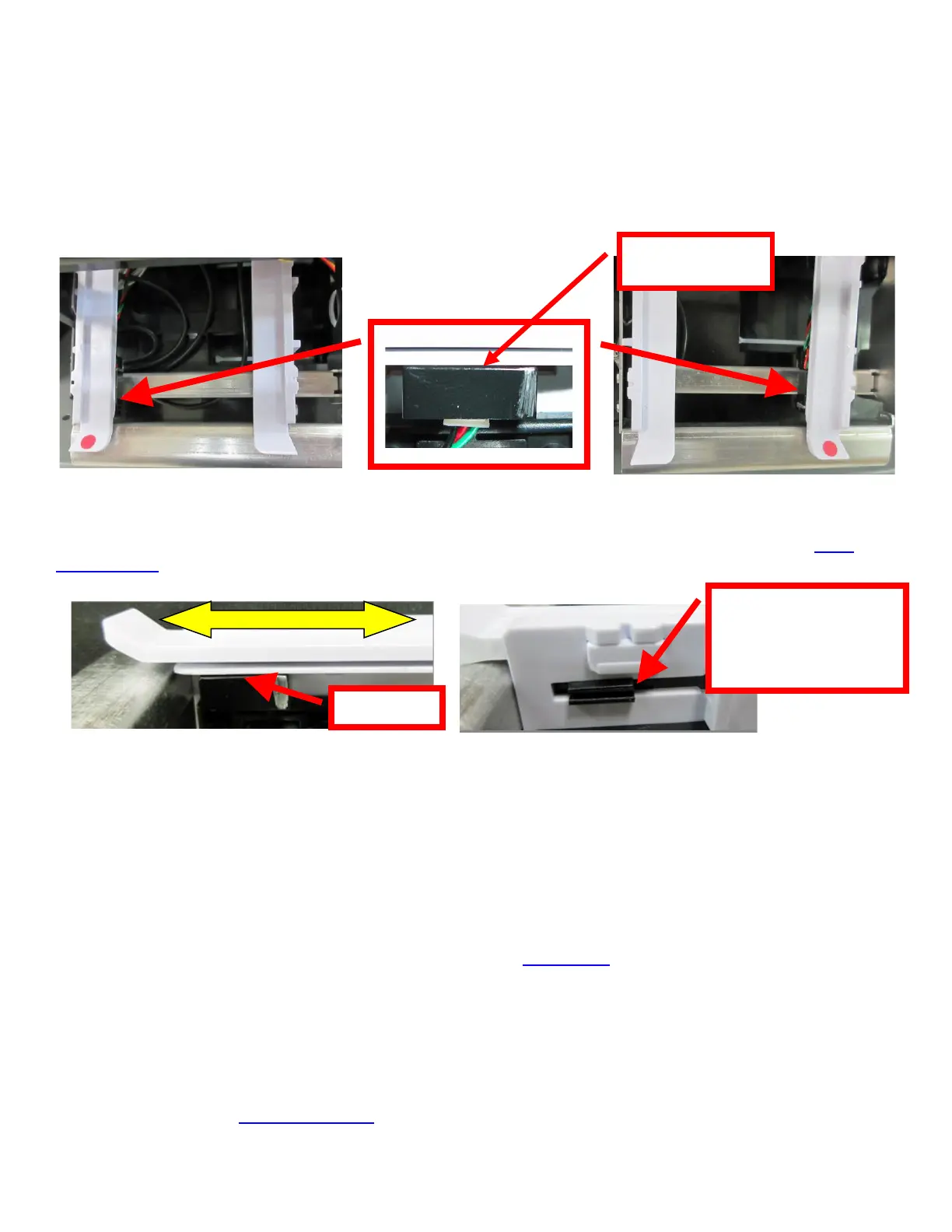

10.1.1 Black Mark Opto Sensor

There is an optical sensor (cut/ tear opto) mounted on white plastic rail that senses the black timing mark on

the ticket stock. This sensor controls the cut or tear position of the media. The sensor may be on either side

of the paper path depending on printer’s configuration. The sensor position is factory set and adjustment

should not be necessary.

Once a year the opto eye should be blown off with air. This interval will vary depending upon the

environment and the quality of the ticket stock.

ADJ4, ADJW and ADJ2 paper path RADJ4 & RADJW paper path

Note: Before making any opto adjustments make sure your ticket stock was manufactured to proper ticket

specifications.

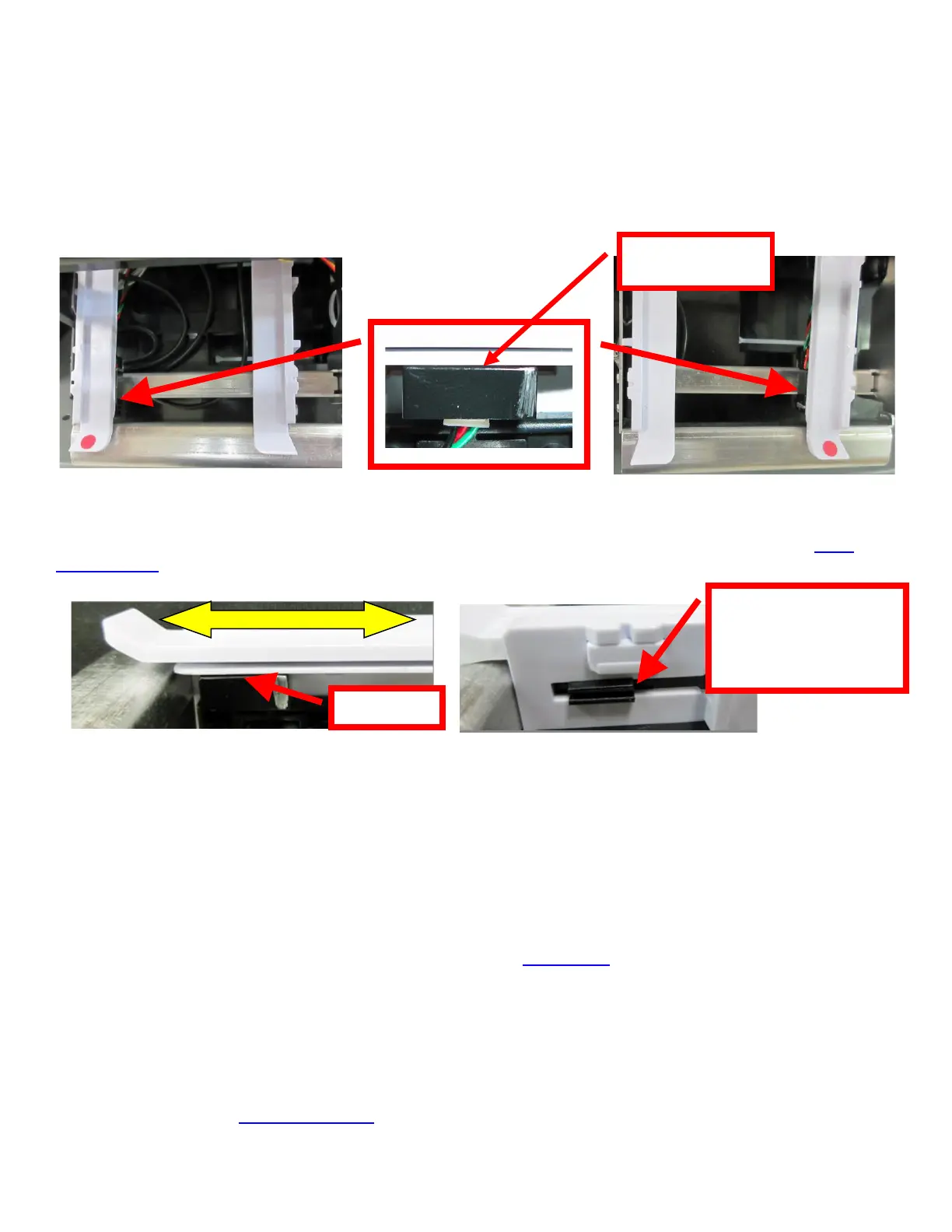

To adjust the cut or tear position, physically adjust the opto mounting bracket forward or backwards to achieve

the desired cut or tear location. On a printer with auto cut the cut position should be a 1/16”-1/8” away from the

ticket perforation. On a Lemur without auto cut the ticket perforation should line up with the edge of the cabinet

or top plate.

You may need to remove the ticket stock in order to physically adjust the black timing mark sensor (opto).

Minor adjustments (no greater than 3/16”) to the cut or tear position may also be done via the control panel (if

applicable) by changing the INC/DEC CUT1/2 settings. (See Appendix A). For a 200dpi printer the INC value

should not exceed 38. For a 300dpi printer the INC value should not exceed 55. Going beyond these values

will cause reliability issues.

If you are not able to get the desired cut position, make sure your ticket stock was manufactured to proper

specifications.

Click here to return to > Table of Contents

Loading...

Loading...