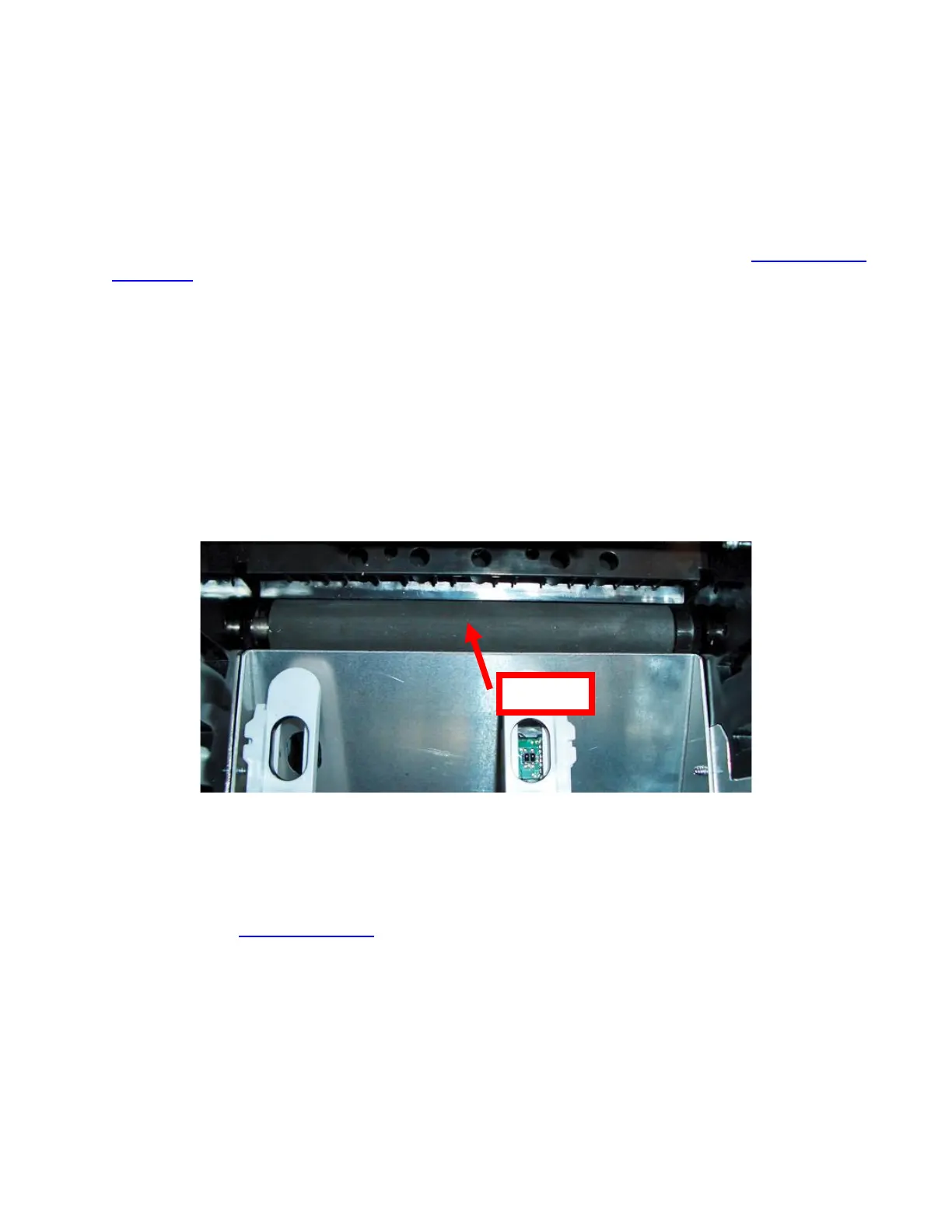

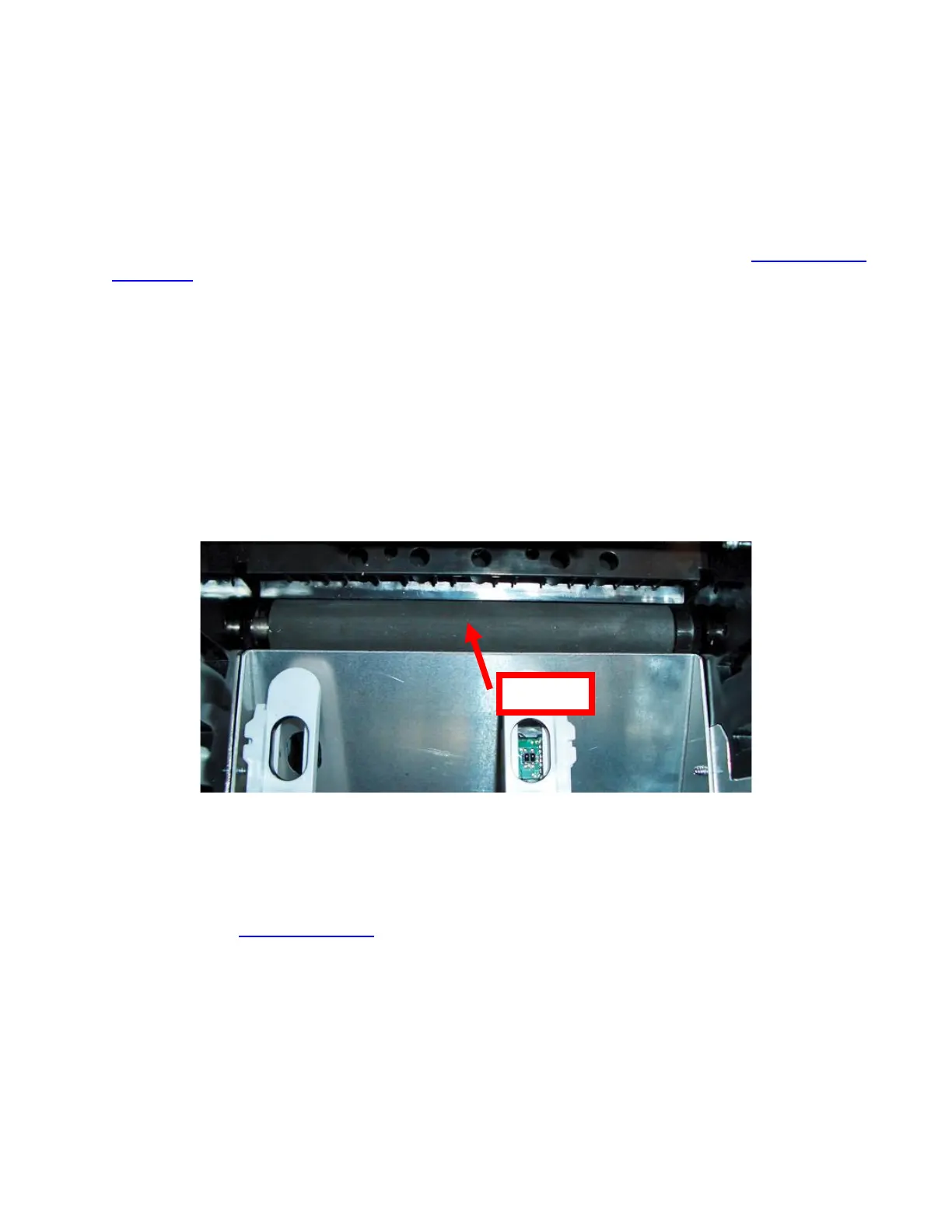

10.1.5 Platen

The Platen (rubber drive roller) should be cleaned once a year to prevent paper dust from building up on the

roller. (NOTE: The platen may require more frequent cleaning in dusty environments or when using inferior

ticket stock.)

The follow needs to be done with the printer powered off and unplugged from the AC source.

1. Make sure power is off and the AC cord is disconnected from the printer

2. Unlock the cam lock lever and remove head mounting block/ plate. (Refer to section 10.1.3 Thermal

Print Head).

3. Apply a small amount of Isopropyl alcohol onto a paper towel to clean the rubber roller. Only clean the

area where the platen makes contact with the media.

4. Clean only the part of the rubber roller where the ticket stock makes contact with.

5. Rotate the rubber roller clockwise a little and repeat step 4; continue in the same manner for one full

revolution of the rubber roller.

6. Install the head mounting block/ plate and lock the cam lock lever back in place. Printer in now ready

for normal operation.

Platen size and color may vary from what is shown in the photos.

Click here to return to > Table of Contents

Loading...

Loading...