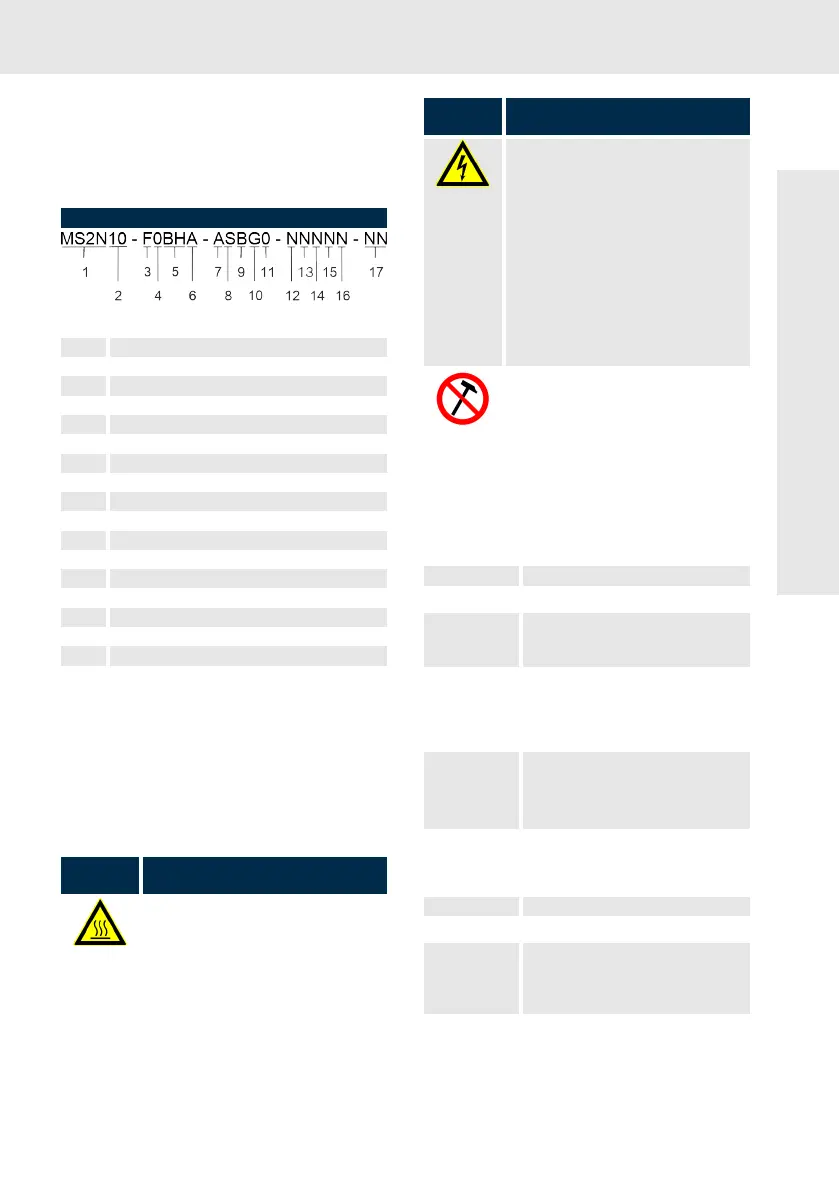

4.2 Type code

The type code is printed onto the type plate of

the motor. For the meaning of the type code refer

to the following details.

Type codes, meaning of the digits

1 Product

2 Frame size

3 Frame length

4 Characteristics of moment of inertia of the rotor

5 Winding code

6 Cooling

7 Encoder performance

8 Encoder design

9 Electrical connection

10 Shaft

11 Holding brake

12 Flange exactness

13 Bearings

14 Frame size

15 Coating

16 Other design

17 Special design

5

About this product

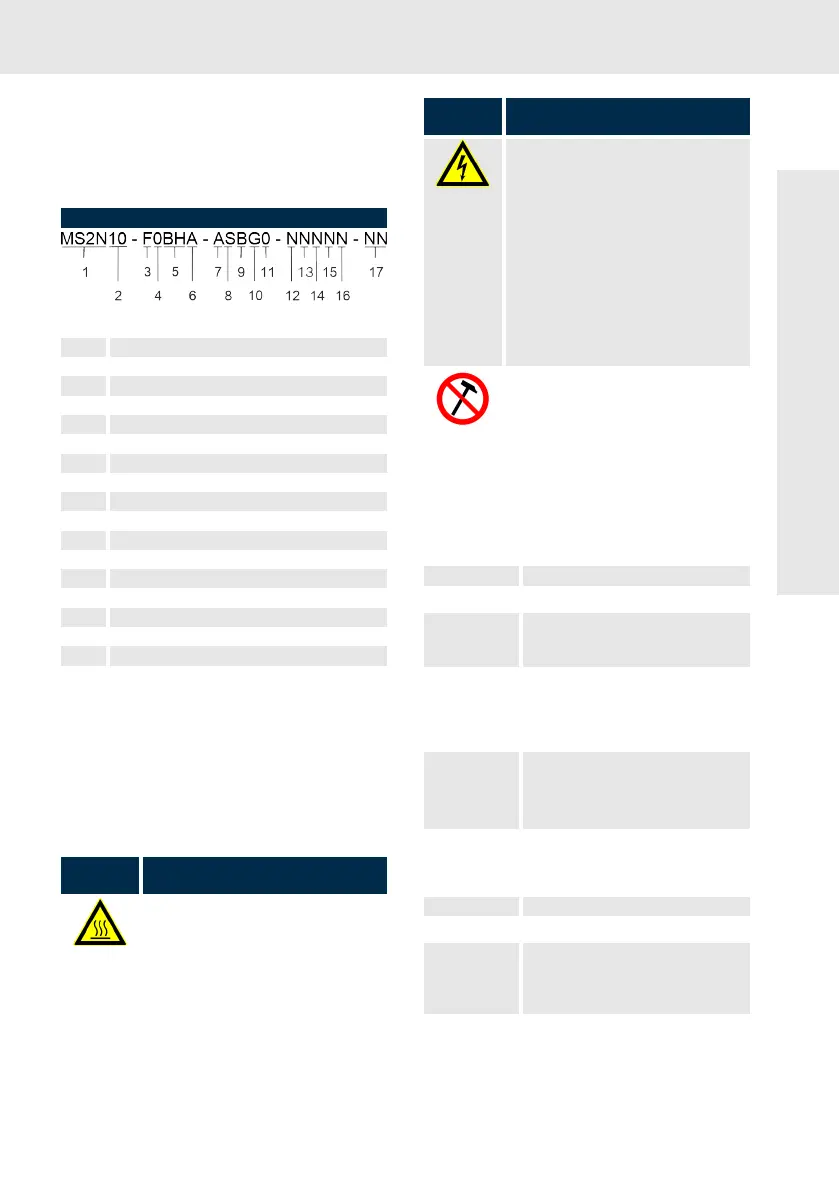

5.1 Safety instructions on the

product

Please note the safety and prohibitive sign on the

motor.

Safety sym-

bols

Meaning

Hot surfaces with temperatures over 60 °C

may cause burns

Let the motors cool down before working

on the motors or in close proximity to the

motors. The thermal time constant stated

in the technical data is a measure for the

cooling time. Cooling down can require up to

140 minutes.

- Wear safety gloves.

- Do not work on hot surfaces.

Safety sym-

bols

Meaning

Warning against dangerous electric voltage

Electric connection may only be established

by specialized staff. Tools for electricians

(VDE tools) are absolutely necessary.

- The installation has to be switched de-ener-

gized before operation and de-energization

must be ensured via a suitable measuring

device. De-energize the machine and secure

the mains switch again unintended or unau-

thorized re-energization.

- Open the terminal boxes only in switched-

off voltage.

Motor damage due to strikes onto the motor

shaft

Do not strike the shaft end and do not

exceed the allowed axial and radial forces

of the motor.

5.2 Features and functions

5.2.1 Basic data

Product 3~ PM motor

Type MS2N

Ambient temper-

ature during

operation

0 ... 40 °C (with derating up to 60 °C)

Type of protec-

tion

IP64 without shaft sealing ring

IP65 with shaft sealing ring

IP67 with sealing air

EN IEC 60034-5:2020

Cooling mode IC410, Self-cooling

IC416, Forced ventilation

IC3W7, Water cooling

EN 60034-6:1993

Motor design IM B5

IM B35 (only MS2N13)

EN 60034-7:1993 + A1:2001

Coating Varnish RAL 9005

Flange similar to DIN 42948:1965-11

Shaft end Cylindrical (DIN 748-3),, centering hole

with thread "DS" (DIN 332-2:1983-05),

optional with keyway (half key balancing

according toISO 21940-32:2012)

Concentricity,

run-out, align-

ment

Tolerance N (standard)

Tolerance R (availability according to type

code)

DIN 42955:1981-12

About this product

Loading...

Loading...