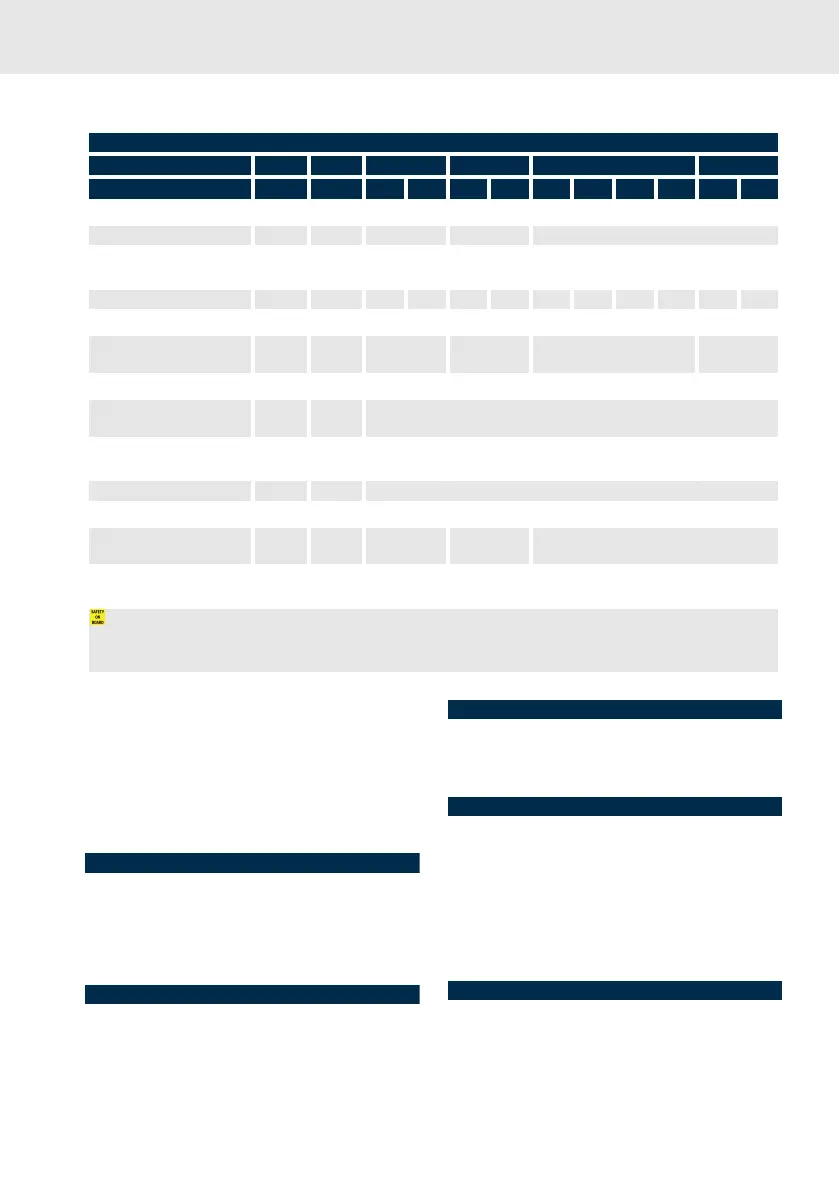

5.2.5 Motor encoder

Technical data motor encoder

BASIC STANDARD ADVANCED HIGH

Designation Symbol Unit AM AS BM BS CM CS HM HS DM DS

Encoder interface - - HIPERFACE® ACURO®-link

Encoder signal periods ~/⑀ - 16 128 -

Functional encoder resolu-

tion (singleturn)

- - 20 bit 24 bit

Distinguishable rotations U

turn

- 4096 1 4,096 1 4,096 1 4,096 1 4,096 1

System accuracy of encoder

1

∢ '' ±520 ±120 ± 36 ± 20

System accuracy typ-

ical/maximum

2)

∢ '' ±360 / ± 520 ±120 ±50 / ± 70 ±20 / ± 30

Encoder output signal V

out

1Vss -

Encoder voltage supply VCC

Encod

er

V 7...12

Encoder max. current con-

sumption

I

Encoder

mA 50 60 130

Functional safety

Safety integrity level - - SIL 2 SIL 3

Performance level

- -

Category 3,

PL d

Category 3, PL e

Position resolution for safe

position

- - 9 bit

1) The installation mechanics can sporadically influence the accuracy of the overall system.

2) Reachable overall system accuracy by taking the installation mechanics into consideration, typical and maximum value.

For more information about Integrated Safety

technology and the requirements to use motors

with encoder systems for Safety technology

applications with IndraDrive, see IndraDrive Inte-

grated Safety Technology “Safe Motion” DOK-

INDRV*-SI3*SMO-VRS-APxx-xx-P.

BASIC

BASIC-Geber “Ax“ uses a capacitive sampling method. Data

output of process data happens analog via SinCos track. Data

output of parameter data (electronic type plate) happens

digitally via Hiperface®-Protocol. The motor temperature is

not transmitted via encoder interface.

STANDARD

STANDARD-Encoder Bx Data output of process data happens

analog via SinCos track. Data output of parameter data (elec-

tronic type plate) happens digitally via Hiperface®-Protocol.

STANDARD

The encoder fulfills the specification for safety technique

according to SIL2 and category 3, PL d. The motor tempera-

ture is not transmitted via encoder interface.

ADVANCED

ADVANCED-Encoder " Cx " / " Hx " use an optical sampling

method. Data output of process and parameter data (elec-

tronic type plate) happens digitally via ACURO®link-Protocol.

The encoder “Cx“ fulfills the specification for safety technique

according to SIL 2 and category 3, PL d. The encoder “Hx“ ful-

fills the specification for safety technique according to SIL 3

and category 3, PL e. The motor temperature is transmitted

digitally.

HIGH

HIGH-Geber " Dx " uses an optical sampling method. Data

output of process and parameter data (electronic type plate)

happens digitally via ACURO®link-Protocol. The encoder ful-

Loading...

Loading...