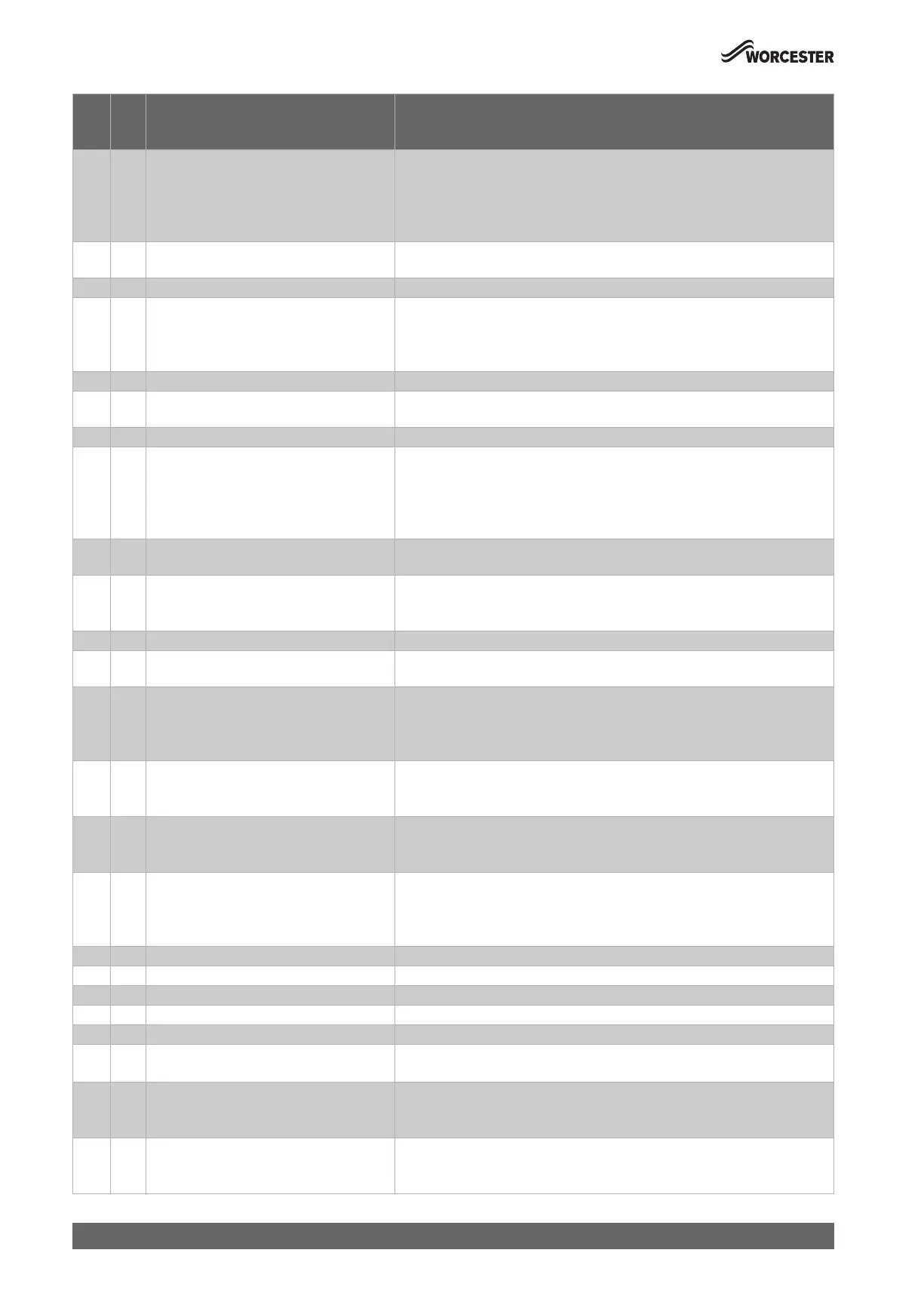

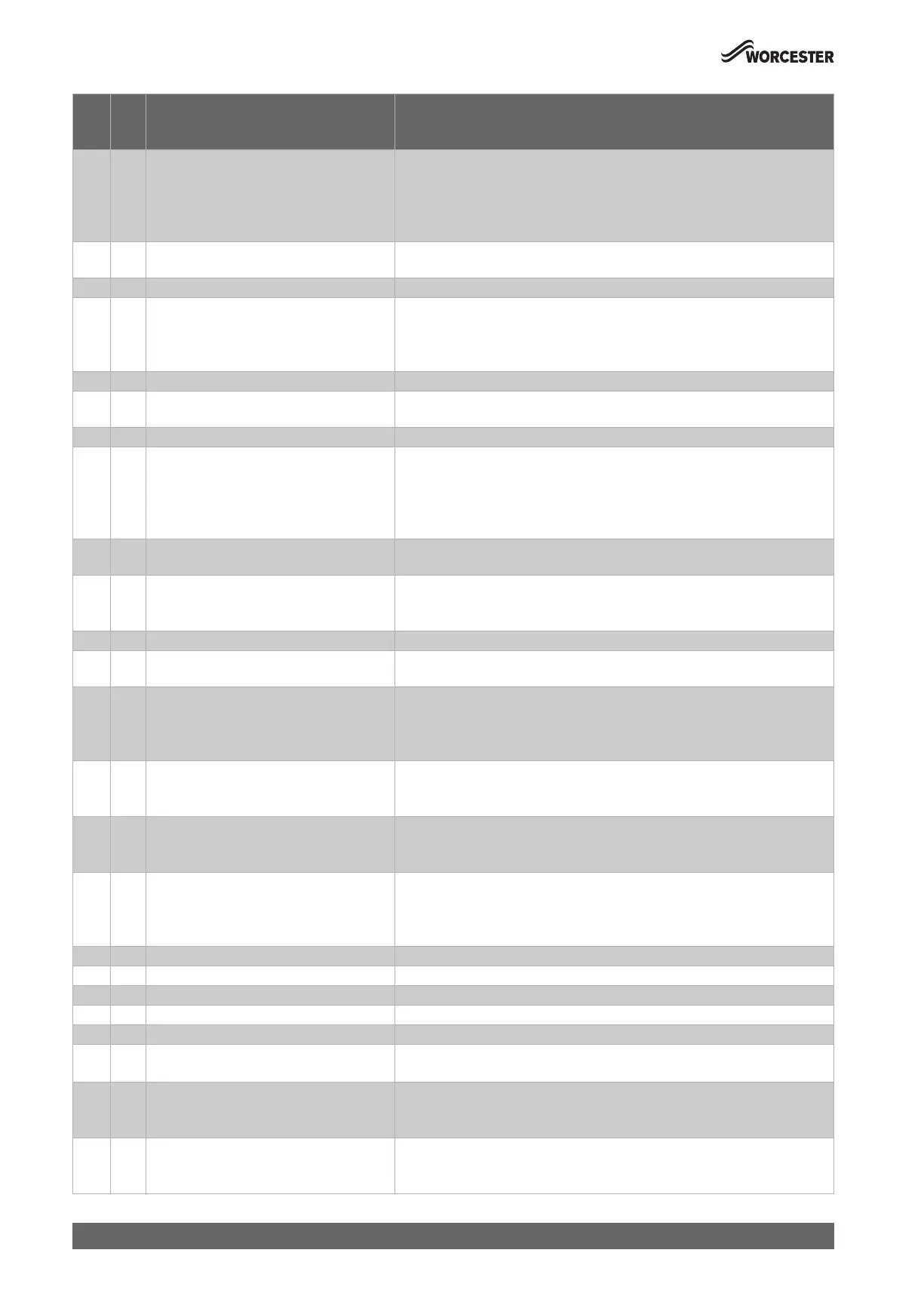

Fault finding and diagnosis

Worcester 2000 – 6 721 814 551 (2019/09)

66

264 B Air feed failed during operating phase. ▶ Reconnect the fan plug properly, perform reset.

▶ Replace fan.

▶ Mains voltage must correspond to the default value.

▶ Remove any blockages in the flue system.

▶ Check venturi/injector for potential blockage.

265 BC Heat energy demand lower than energy

supplied.

–

268 – Component test mode. Not applicable, is status message.

269 V Flame monitoring. ▶ Reset appliance electronics - factory reset.

▶ Replace the appliance electronics.

▶ Check flame sense electrodes and connections.

▶ Check earth connections.

270 BC The heat source has started up. –

273 O Operation interrupted: safety inspection

following 24 hours of continuous operation.

–

275 O Test code plug detected. –

281 – Pump stuck or running dry. ▶ Replace the pump.

▶ Vent the system.

▶ Check operating pressure.

▶ Check low pressure switch.

▶ Check pump connections (hydraulic and electrical).

305 BC Boiler cannot start temporarily following DHW

priority.

System appliance only.

306 V After switching gas off: Flame is detected. ▶ Check the gas valve, replace if required.

▶ Check electrodes and connecting leads, replace if required.

▶ Replace the appliance electronics.

323 – Control communication fault. –

328 V Mains voltage briefly interrupted. ▶ Check for voltage interruption between electrical wiring system of the building and

the appliance.

341 B Heat source temperature increase too rapid. ▶ Open isolation valves.

▶ Connect plug to pump.

▶ Replace pump.

▶ Ensure circulating pump is set on Constant speed mode - curve III.

342 BC Temperature increase in DHW mode too rapid. ▶ If the water pressure is too low, top up with water and vent the system.

▶ Open service valves in the cylinder charging circuit.

▶ Replace the diverter valve / cylinder primary pump.

350 B Flow temperature sensor short circuit. ▶ Check and replace flow temperature sensor and harness Section 13.2.1.

▶ Check and replace the connecting lead to the flow temperature sensor.

▶ Check and replace control unit/burner control unit.

351 B Flow temperature sensor failure. ▶ Connect the plug to the flow temperature sensor.

▶ Check and replace flow temperature sensor and harness Section 13.2.1.

▶ Check and replace the connecting lead to the flow temperature sensor.

▶ Check and replace control unit/burner control unit.

356 B Supply voltage for heat source too low. ▶ Establish supply voltage of at least 196 VAC.

357 BC Venting program –

358 BC Active anti-seizing function. Blocking protection for the heating pump and diverter valve active

360 V Incorrect code plug. ▶ Check code plug, replace if necessary.

362 V Service code plug detected. ▶ Check code plug, replace if necessary.

363 V System fault, appliance electronics: fault when

testing the ionisation signal.

▶ Check earthing connections.

▶ Reset appliance electronics, replace if necessary.

364 V Solenoid valve EV2 leaking. ▶ Check the gas valve, replace if required.

▶ Check electrodes and connecting leads, replace if required.

▶ Check and replace the appliance electronics.

365 V Solenoid valve EV1 leaking. ▶ Check the gas valve, replace if required.

▶ Check electrodes and connecting leads, replace if required.

▶ Check and replace the appliance electronics.

Fault

code

Fault

category

Description Remedy

Loading...

Loading...