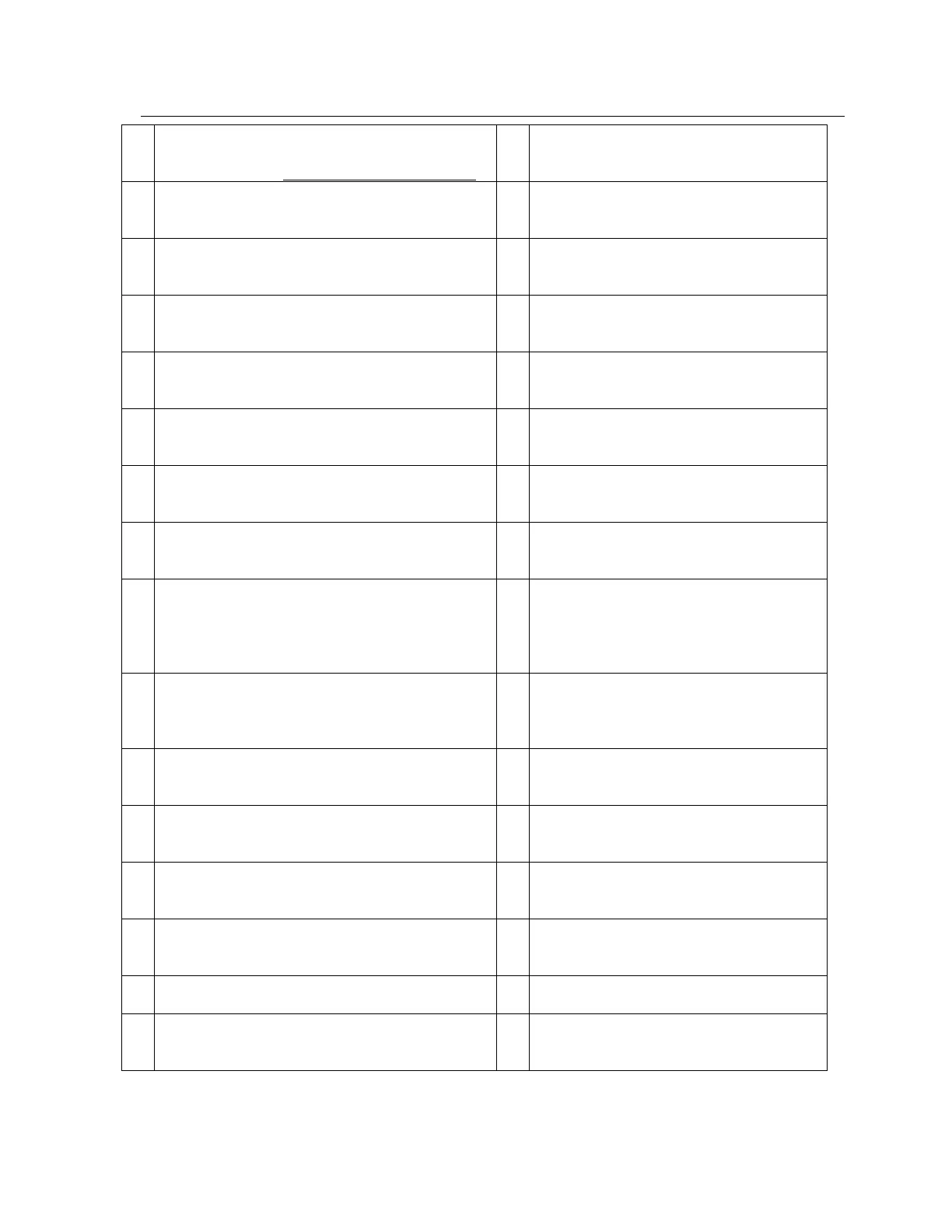

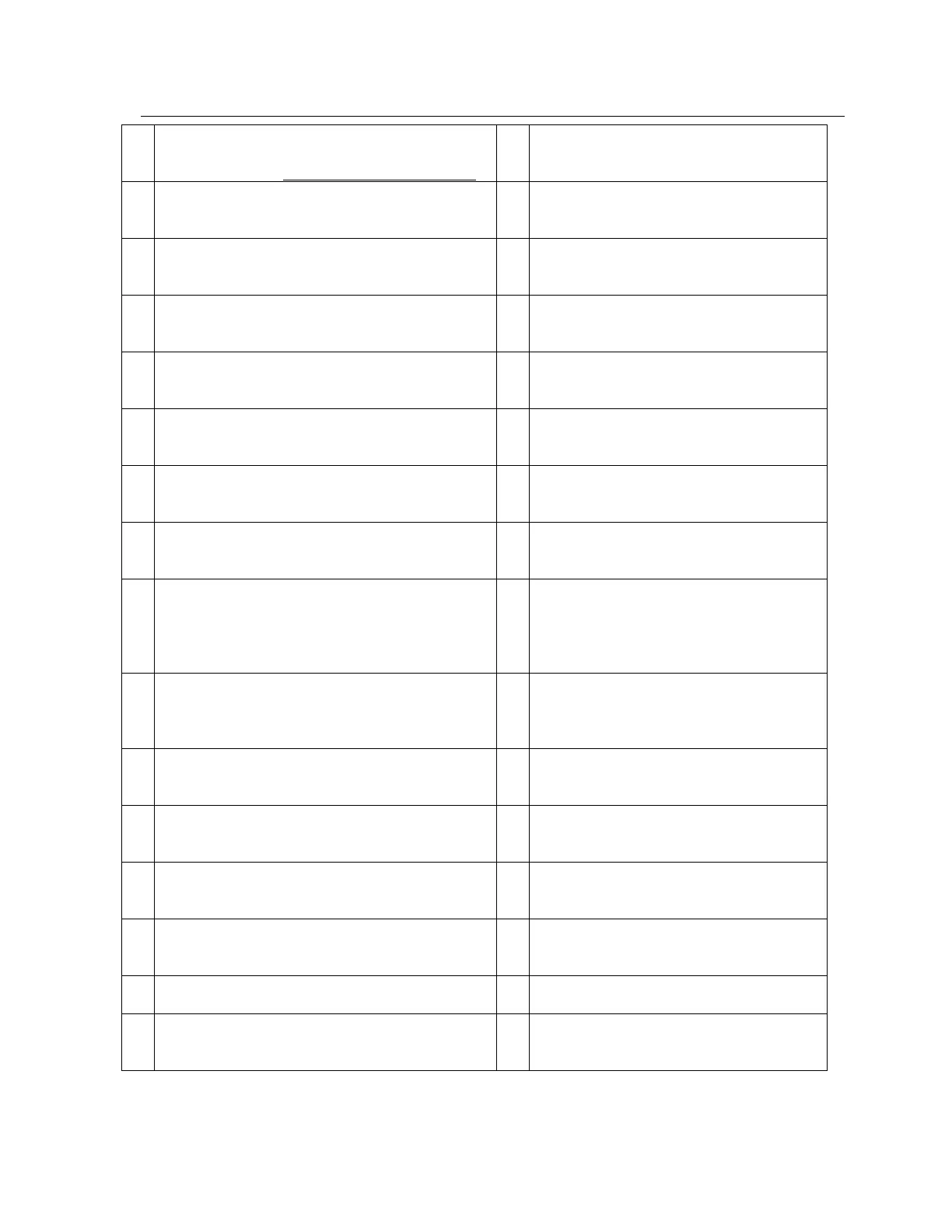

50

10 Operating and Monitoring Systems 10

1 Sight-glass, refrigeration unit:

For visually checking whether the cooling agent

is free of bubbles during the adsorption phase

17 Thermal sensor, distillation condenser:

Monitors the solvent temperature.

2 High pressure control switch (refrigeration):

Switches the system to the malfunction state if

there is overpressure

18 SPP sprayer:

See SPRAYMATIC SPP instructions.

3 Low pressure control switch (refrigeration):

Switches the system to the malfunction state if

there is not enough cooling agent

19 Drying time controller:

Extends the drying time, depending on

the type and amount of garments

4 Pressure gauge, steam pressure (elec):

For checking operating pressure and sealing

(when cooled off, approximately –0.8 bar).

20 Sight-glass, safety separator **:

For observing the process water and

checking the tank.

5 Overfill preventer, distillation **:

Prevents overfilling the still (over 75 % of its

filling volume).

21 Sight-glass, tank 3:

You can read off the liquid level on the

scale.

6 Cooling water regulator, refrigeration unit:

You can set the condensation pressure in the

refrigeration unit here.

22 Sensor, high level:

Regulates the detergent solution level.

7 Cooling water regulator, distillation:

Controls the cooling water flow (setting for

cooling water temperature drain +45°C/113°F).

23 Thermal sensor, solvent:

Monitors the solvent temperature.

8 Pressure gauge, compressed air:

You can read off the required operating

pressure (6 bar) on the pressure gauge

24 Thermal sensor, cage housing outlet:

Monitors the housing outlet temperature

9 Safety thermostat, air heater (elec):

Monitors the maximum permissible temperature

on electrically heated machines The system

switches to the malfunction state in case of

overheating

25 Thermal sensor, air heater (elec):

sensor from safety thermostat 9

10 Sight-glass, water separator:

For observing the condensate feed from

distillation and drying

26 Thermal sensor, aftercooler:

Monitors the aftercooler temperature and

switches the machine off when the

temperature exceeds 40° C (104°F).

11 Pushbutton, dosing unit:

Triggers a dosing procedure when pushed. You

can select any number of lifts

27 Safety valve, steam heater (elec):

Opens when the permissible pressure is

exceeded

12 Water drain valve:

For draining the water trap

28 Aeration valve, steam heater (elec):

Aeration when filling the heating chamber

with water.

13 Dosing unit:

Use the setting screw to select the required

product quantity per lift.

29 Thermal sensor, distillation:

Turns off the distillation heater

14 Pressure control switch, steam chest distillation

(elec):

Controls the distillation heater

30 Heating element, overheating protection

(elec): monitors the water level in the

heating chamber.

15 Sight-glass, still:

For observing the distillation process

16 Limit switches:

All maintenance openings are protected with

limit switches

* only on US model

** only on machines that conform to the EN ISO 8230 standard

P12

Loading...

Loading...