13

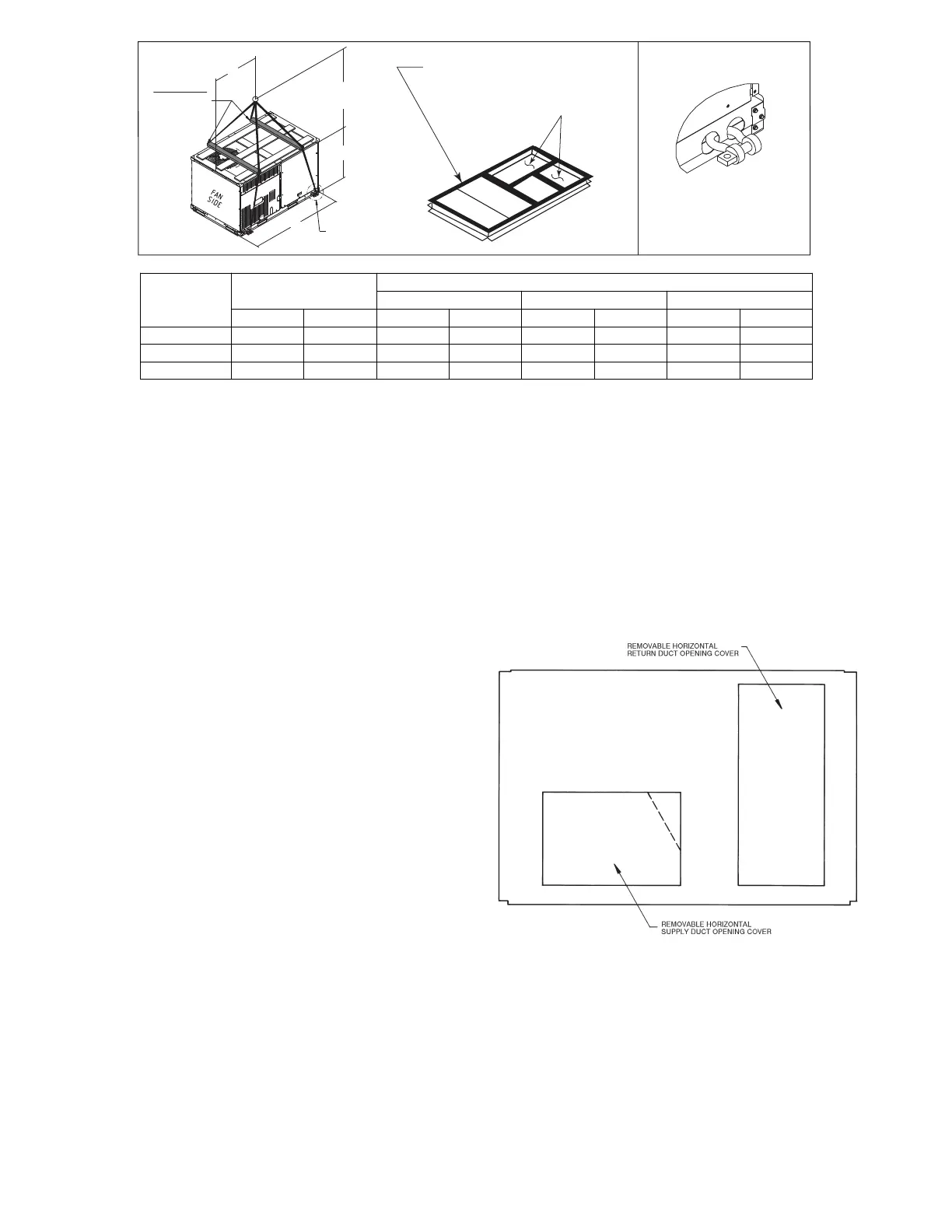

DETAIL “A”

PLACE ALL SEAL STRIP IN PLACE

BEFORE PLACING UNIT ON ROOF CURB.

DUCT END

SEE DETAIL “A”

“C”

“B”

“A”

914-1371

(36"-54")

SPREADER

BARS

REQUIRED

C10410

UNIT

MAX WEIGHT

DIMENSIONS

A B C

LB KG IN. MM IN. MM IN. MM

549J*07A/D 1100 500 88.0 2235 40.8 1035 41.5 1055

549J*08D 1315 598 88.0 2235 41.6 1057 49.5 1257

549J*09D 1505 684 88.0 2235 40.0 1015 49.5 1257

NOTES:

1. Dimensions in ( ) are millimeters.

2. Hook rigging shackles through holes in base rail, as shown in detail “A.” Holes in base rails are centered

around the unit center of gravity. Use wooden top to prevent rigging straps from damaging unit.

Fig. 9 -- Rigging De tails

When using t he standard side drain connection, ensure the

red plug in the alternate bottom connection is tight. Do

this before setting the unit in place. The red drain pan

plug can be tighte ned with a

1

/

2

--in. square socket drive

extension. For further details see “Step 9 -- Install External

Condensate Trap and Line” on page 15.

Before setting the unit onto the curb, recheck gasketing on

curb.

PositioningonCurb—

Position unit on roof curb so that the following clearances

are maintained:

1

/

4

in. (6.4 mm) clearance between the

roof curb and the base rail inside the front and rear, 0.0 in.

clearance between the roof curb and the base rail inside on

the duct end of the unit. This will result in the distance

betwee n the roof curb and the base rail i nside on the

condenser end of the unit bei ng approxim ate ly

1

/

4

in.

(6.4 mm).

Although unit is weatherproof, guard against water from

higher level runoff and overhangs.

For size 08 and 09 units: after unit is in position, remove

the compressor access panel. Holding the blocking

betwee n compressors with one hand, cut the strapping.

Careful ly remove the blocking without damaging t ubing,

wiring, or controls. Remove the strapping and re place the

access panel.

Remove al l shipping materials and top skid. Recycle or

dispose of all shipping materials.

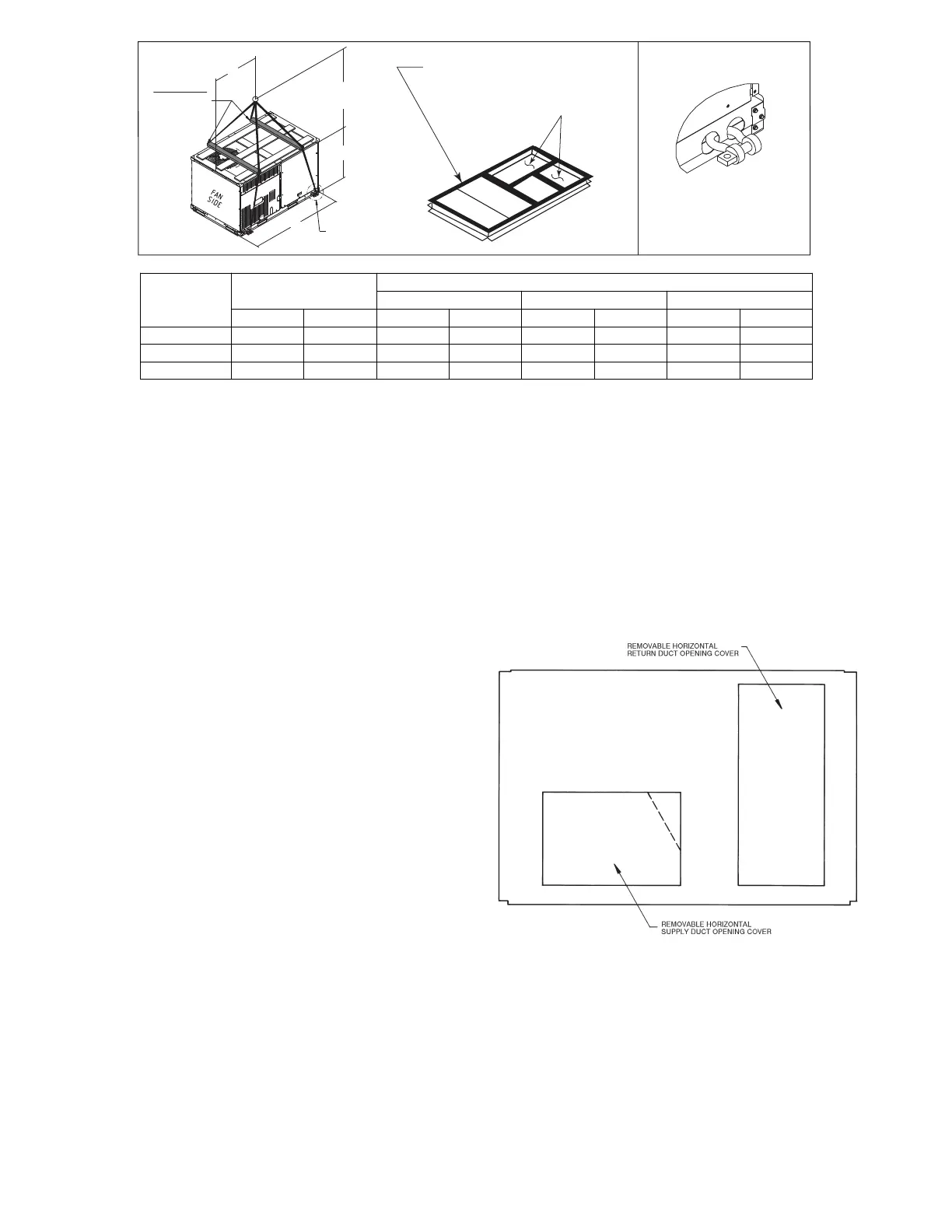

Step 7 — Convert to Horizontal and Connect

Ductwork (when required)

Unit is shipped in the vertical duct configuration. Unit

without factory--installed economizer or return air smoke

detector option may be field--converted to horizontal ducted

configuration. T o convert to horizontal configuration,

remove screws from side duct opening covers and remove

covers. Using the same screws , ins tall covers on vertical

duct openings with the insulation--side down. Seals around

duct openings must be tight. See Fig. 10.

C06108

Fig. 10 -- Horizontal Conversion Panels

Field--supplied flanges should be attached to horizontal

duct openings and all ductwork should be secured to the

flanges. Insulate and weatherproof all external ductwork,

joints, and roof or building openings with counter flashing

and mastic in accordance with applicable codes.

Do not cover or obscure visibility to the unit’s informative

data plate when insulating horizontal ductwork.

Loading...

Loading...