57

5. Press the ▲ button to increase (change) the displayed

parameter value.

6. Press the ▼ button to decrease (change) the displayed

parameter value.

NOTE: When values are displayed, pressing and holding the

▲ or ▼ button causes the display to automatically increment or

decrement.

1. Press the (Enter) button to accept the displayed value

and store it in nonvolatile RAM. “CHANGE STORED”

displays.

2. Press the (Enter) button to return to the current menu

parameter.

3. Press the (Menu Up/Exit) button to return to the previ-

ous menu.

Menu Structure

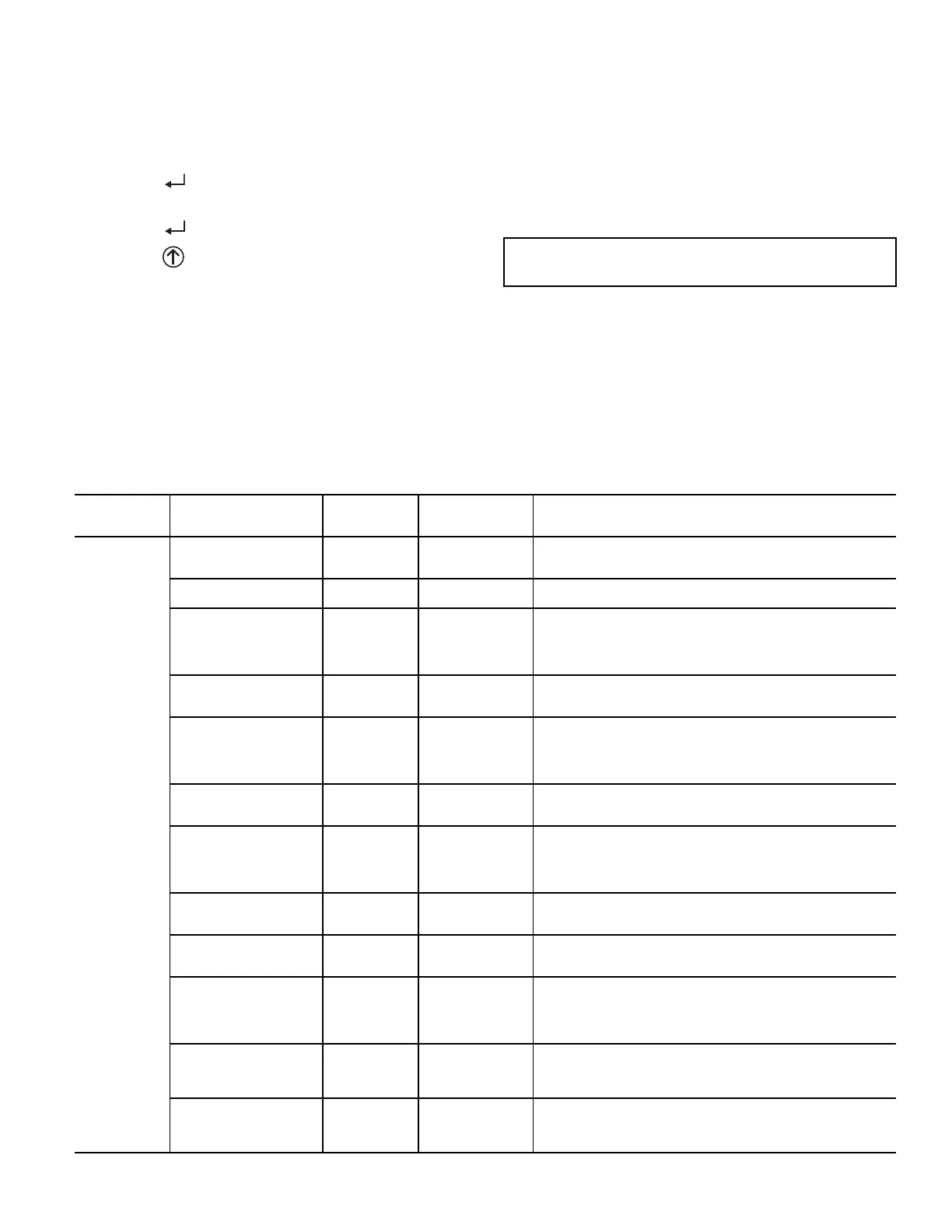

Table 27 illustrates the complete hierarchy of menus and parame-

ters for the EconoMi$er

®

X system.

The Menus in display order are:

•STATUS

• SETPOINTS

• SYSTEM SETUP

• ADVANCED SETUP

•CHECKOUT

•ALARMS

NOTE: Some parameters in the menus use the letters MA or

MAT, indicating a mixed air temperature sensor location before

the cooling coil. This unit application has the control sensor

located after the cooling coil, in the fan section, where it is desig-

nated as (Cooling) Supply Air Temperature or SAT sensor.

SETUP AND CONFIGURATION

Before being placed into service, the W7220 Economizer module

must be set up and configured for the installed system.

The setup process uses a hierarchical menu structure that is easy to

use. Press the ▲ and ▼ arrow buttons to move forward and back-

ward through the menus and press the button to select and confirm

setup item changes.

Time-Out and Screensaver

When no buttons have been pressed for 10 minutes, the LCD

displays a screen saver, which cycles through the Status items.

Each Status items displays in turn and cycles to the next item af-

ter 5 seconds.

IMPORTANT: During setup, the economizer module is

live at all times.

Table 27 — W7220 Menu Structure*

MENU PARAMETER

PARAMETER

DEFAULT

VALUE

PARAMETER

RANGE AND

INCREMENT

†

EXPANDED PARAMETER NAME

Notes

STATUS

ECON AVAIL NO YES/NO

FIRST STAGE COOLING DEMAND (Y1–IN)

YES = economizing available; the system can use outside air for

free cooling when required

ECONOMIZING NO YES/NO

FIRST STAGE COOLING RELAY OUTPUT

YES = outside air being used for first stage cooling

OCCUPIED NO YES/NO

OCCUPIED

YES = OCC signal received from space thermostat or unitary

controller

YES = 24 vac on terminal OCC

NO = 0 vac on terminal OCC

HEAT PUMP N/A**

COOL

HEAT

HEAT PUMP MODE

Displays COOL or HEAT when system is set to heat pump

(Non-conventional)

COOL Y1—IN OFF ON/OFF

FIRST STAGE COOLING DEMAND (Y1-IN)

Y1–I signal from space thermostat or unitary controller for cooling

stage 1.

ON = 24 vac on terminal Y1–I

OFF = 0 vac on terminal Y1–I

COOL Y1—OUT OFF ON/OFF

FIRST STAGE COOLING RELAY OUTPUT

Cool stage 1 Relay Output to stage 1 mechanical cooling

(Y1–OUT terminal)

COOL Y2—IN OFF ON/OFF

SECOND STAGE COOLING DEMAND (Y2–IN)

Y2–I signal from space thermostat or unitary controller for

second stage cooling.

ON = 24 vac on terminal Y2–I

OFF = 0 vac on terminal Y2–I

COOL Y2—OUT OFF ON/OFF

SECOND STAGE COOLING RELAY OUTPUT

Cool Stage 2 Relay Output to mechanical cooling

(Y2–OUT terminal)

MA TEMP

_ _ . _ °F

(or _ _ . _ °C)

–40°F to 150°F

(–40°C to 66°C)

SUPPLY AIR TEMPERATURE, Cooling Mode

Displays value of measured mixed air from MAT sensor.

Displays _ _ . _ F if not connected, short or out of range.

DA TEMP

_ _ . _ °F

(or _ _ . _ °C)

–40°F to 150°F

(–40°C to 66°C)

DISCHARGE AIR TEMPERATURE, after Heating section

Displays when Discharge Air Sylk Bus sensor is connected and

displays measured discharge temperature.

Displays _ _ . _F if sensor sends invalid value, if not connected,

short or out of range.

OA TEMP

_ _ . _ °F

(or _ _ . _ °C)

–40°F to 140°F

(–40°C to 60°C)

OUTSIDE AIR TEMP

Displays measured value of outdoor air temperature.

Displays _ _ . _F if sensor sends invalid value, short or out of

range.

OA HUM _ _ % 0 to 100%

OUTSIDE AIR RELATIVE HUMIDITY

Displays measured value of outdoor humidity from OA Sylk Bus

sensor.

Displays _ _% if not connected short, or out of range.

Loading...

Loading...