13

Installation

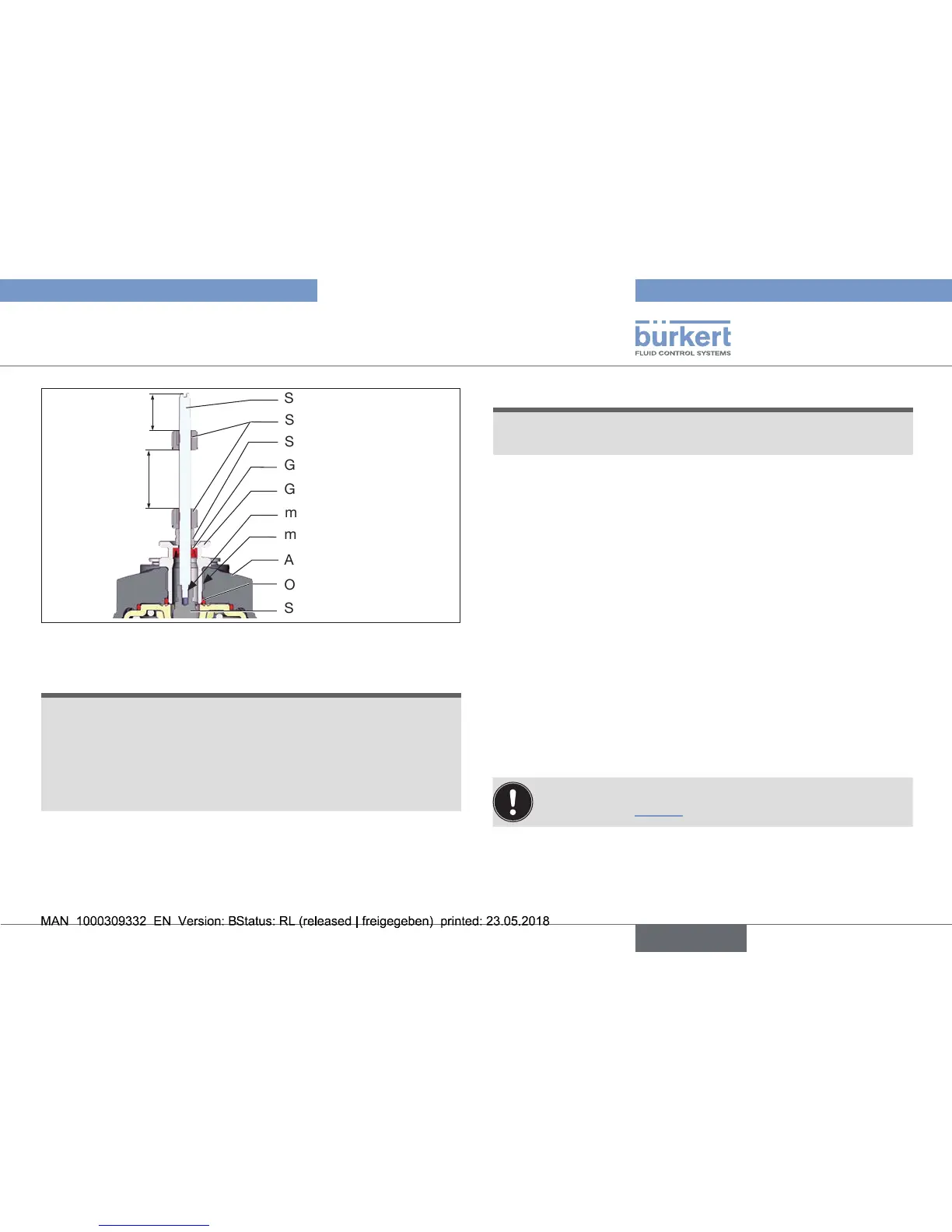

O-ring

Spindle extension

Guideelement

Actuatorcover

Groovering

Switch spindle

Switch cam

3

max.5Nm

max.1Nm

Spacersleeve

Maximum

distance

Fig. 7: Installation of switch spindle (2), 21xx series

NOTE!

Improper installation may damage the groove ring in the

guide element.

Thegrooveringisalreadybepre-assembledintheguide

elementandmustbe“lockedintoposition”intheundercut.

▶ Wheninstallingtheswitchspindle,donotdamagethegroove

ring.

→ Push the switch spindle through the guide element.

NOTE!

Screw locking paint may contaminate the groove ring.

▶ Donotapplyanyscrewlockingpainttotheswitchspindle.

→ Tosecuretheswitchspindle,applysomescrewlockingpaint

(Loctite290)inthetappedboreofthespindleextensioninthe

actuator.

→ CheckthattheO-ringiscorrectlypositioned.

→ Screwtheguideelementtotheactuatorcover

(maximumtorque:5Nm).

→ Screwswitchspindleontothespindleextension.Todothis,

thereisaslotontheupperside(maximumtorque:1Nm).

→ Pushspacersleeveonto the switchspindle up totheguide

element.

Position switch cams on the switch spindle:

→ Pushlowerswitchcamuptothespacersleeve.

→ Pushupperswitchcamuntil3mmfromthestartoftheswitch

spindle.

Ensure that the distance between both switch cams is

maximum (see “Fig.7”).

Loading...

Loading...