15

Installation

7.3. Installation on process valves of

series 20xx

Procedure:

1. Install switch spindle

Transparent cap

Position indicator

Actuator

Fig. 10: Installation of the switch spindle (1), series 20xx

→ Unscrew the transparent cap on the actuator.

→ Usingahexagonsocketkey,unscrewtheorange/yellowposition

indicatorfromtheinsideoftheactuator.

→ PresstheO-ringdownwardsintothecoveroftheactuator

(see “Fig.11”).

→ Manually screw the switch spindle (and the plugged-on guide

element)togetherwiththeplasticpartontothespindleofthe

actuator,butdonottightenspindleyet.

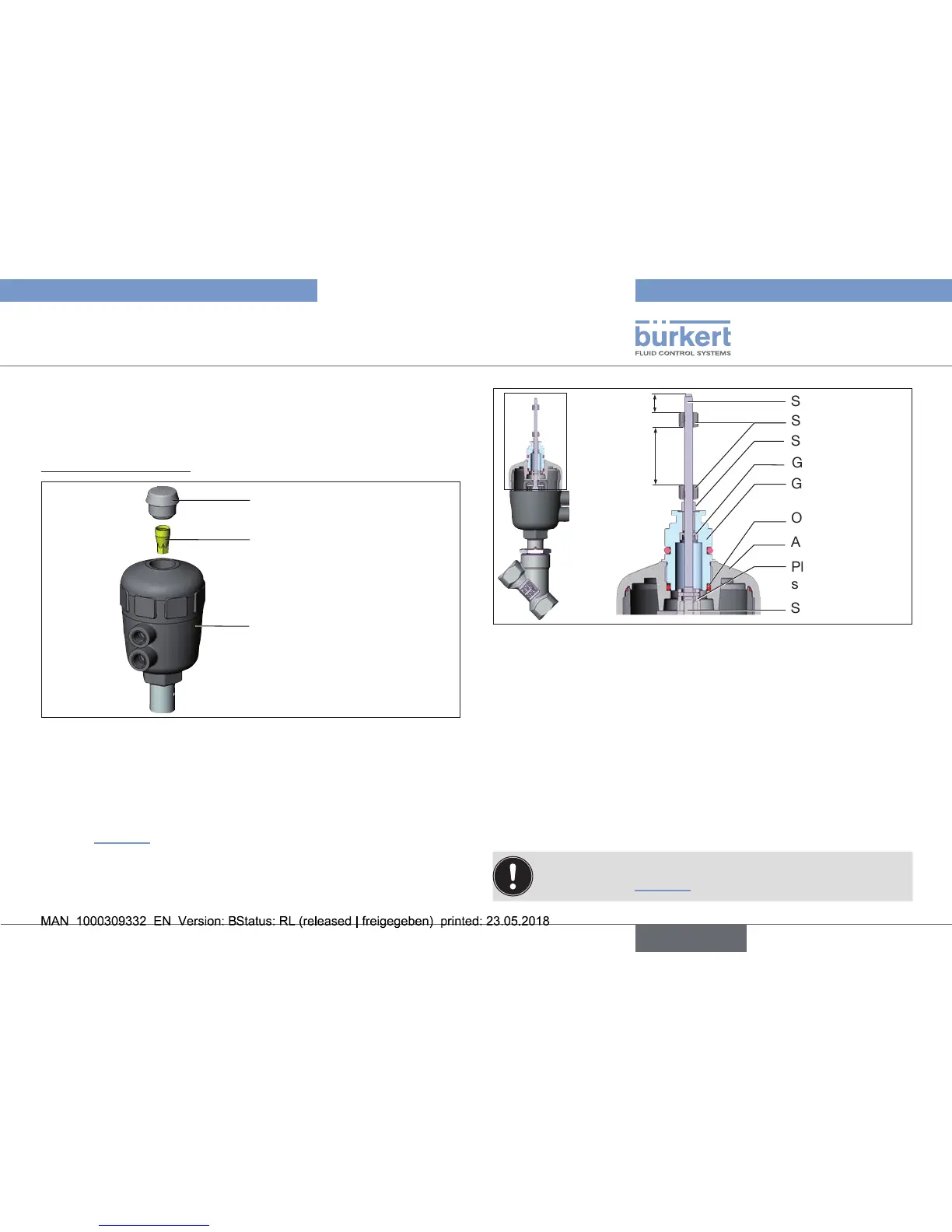

Guideelement

O-ring

Plasticpartofthe

switch spindle

Switch cam

Switch spindle

Spindle (actuator)

Actuatorcover

Groovering

3

Spacersleeve

Maximum

distance

Fig. 11: Installation of the switch spindle (2), series 20xx

→ Tighten the guide element with a wrench SW19 into the actuator

cover(torque:8.0Nm).

→ Tighten the switch spindle on the spindle of the actuator.

Todothis,thereisaslotontheupperside(torque:1.0Nm).

→ Pushspacersleeveonto the switchspindle up totheguide

element.

→ Position switch cams on the switch spindle:

→ Pushlowerswitchcamuptothespacersleeve.

→ Pushupperswitchcamuntil3mmfromthestartoftheswitch

spindle.

Ensure that the distance between both switch cams is

maximum (see “Fig.11”).

Loading...

Loading...