8 | Maintenance

54 / 68 0870211676_RA0760A_PLUS_-0004_IM_en

CAUTION

Failing to properly maintain the machine.

Risk of injuries!

Risk of premature failure and loss of efficiency!

• Respect the maintenance intervals or ask your Busch representative for service.

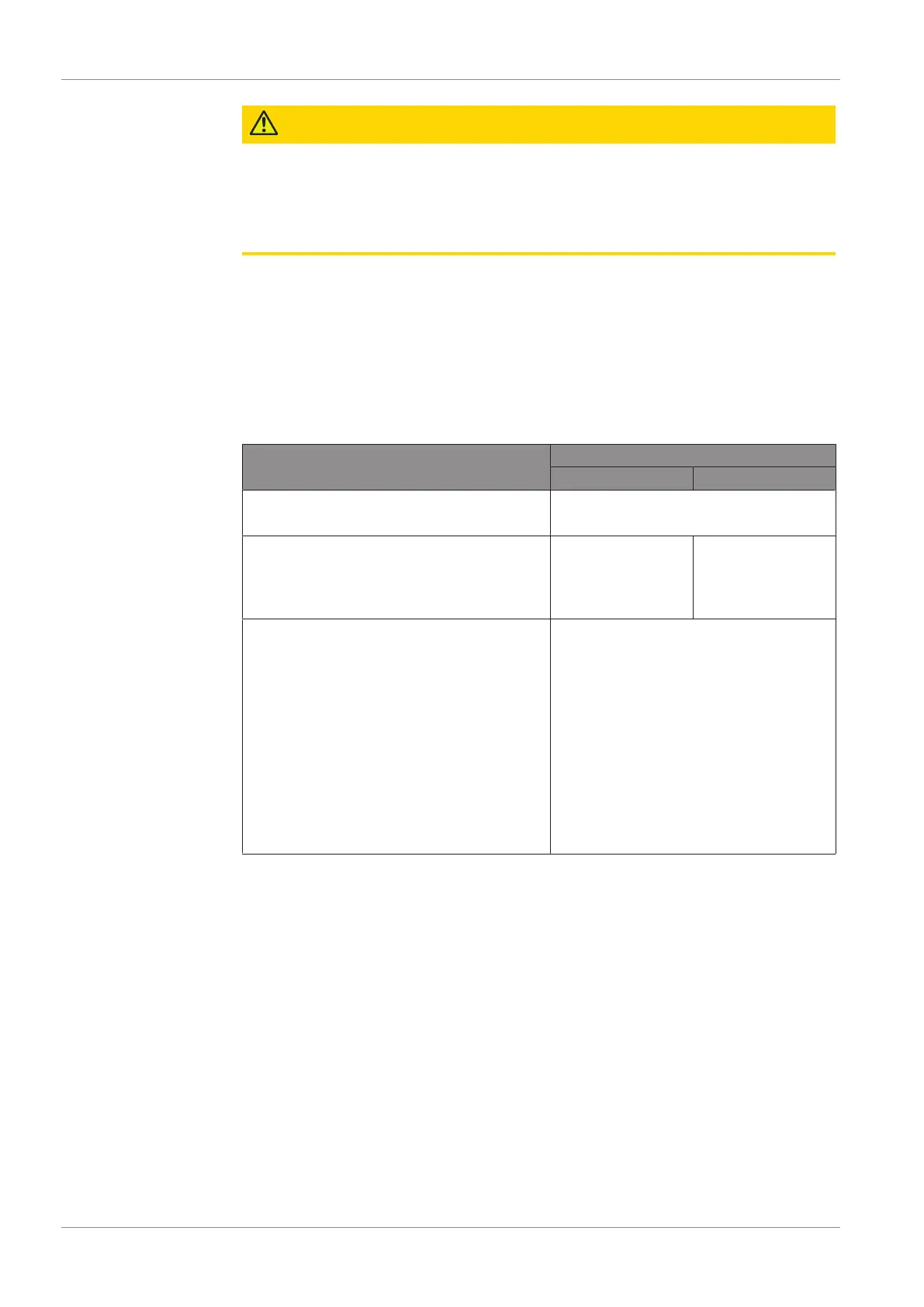

8.1 Maintenance Schedule

The maintenance intervals depend very much on the individual operating conditions. The

intervals given below are considered as starting values which should be shortened or ex-

tended as appropriate. Particularly harsh applications or heavy duty operation, such as

high dust loads in the environment or in the process gas, other contamination or ingress

of process material, can make it necessary to shorten the maintenance intervals signifi-

cantly.

Maintenance work Interval

Normal application Harsh application

• Check the oil level, see Oil Level Inspec-

tion [►56].

Weekly

• Change the oil*, the oil filter* (OF) and

the exhaust filters (EF).

See Oil and Oil Filter Change [►56] and

Exhaust Filter Change [►58].

Max. after 4000

hours, at the latest

after 1 year

Max. after 2000

hours, at the latest

after 6 months

• Clean the machine from dust and dirt, espe-

cially the cooling air inlet and outlet (CAI/

CAO), see Machine Cleaning [►59].

• Air-cooled vacuum pump: clean the cool-

ing air inlet and outlet (CAI/CAO), see

Machine Cleaning [►59].

• Water-cooled vacuum pump: check the

water filter (WF), clean if necessary

• Check the inlet filter cartridge, change it if

necessary, see Inlet Filter Cartridge

Change [►60].

Every 6 months

* Service interval for synthetic oil, shorten the interval when using mineral oil, contact

Busch Service

To visualise information about remaining hours:

• Go to “MAINTENANCE” > “SERVICE”.

• Check when the maintenance tasks have to be performed and how long the machine

has operated since the first commissioning or last maintenance task.

Loading...

Loading...