Troubleshooting | 12

0870211676_RA0760A_PLUS_-0004_IM_en 63 / 68

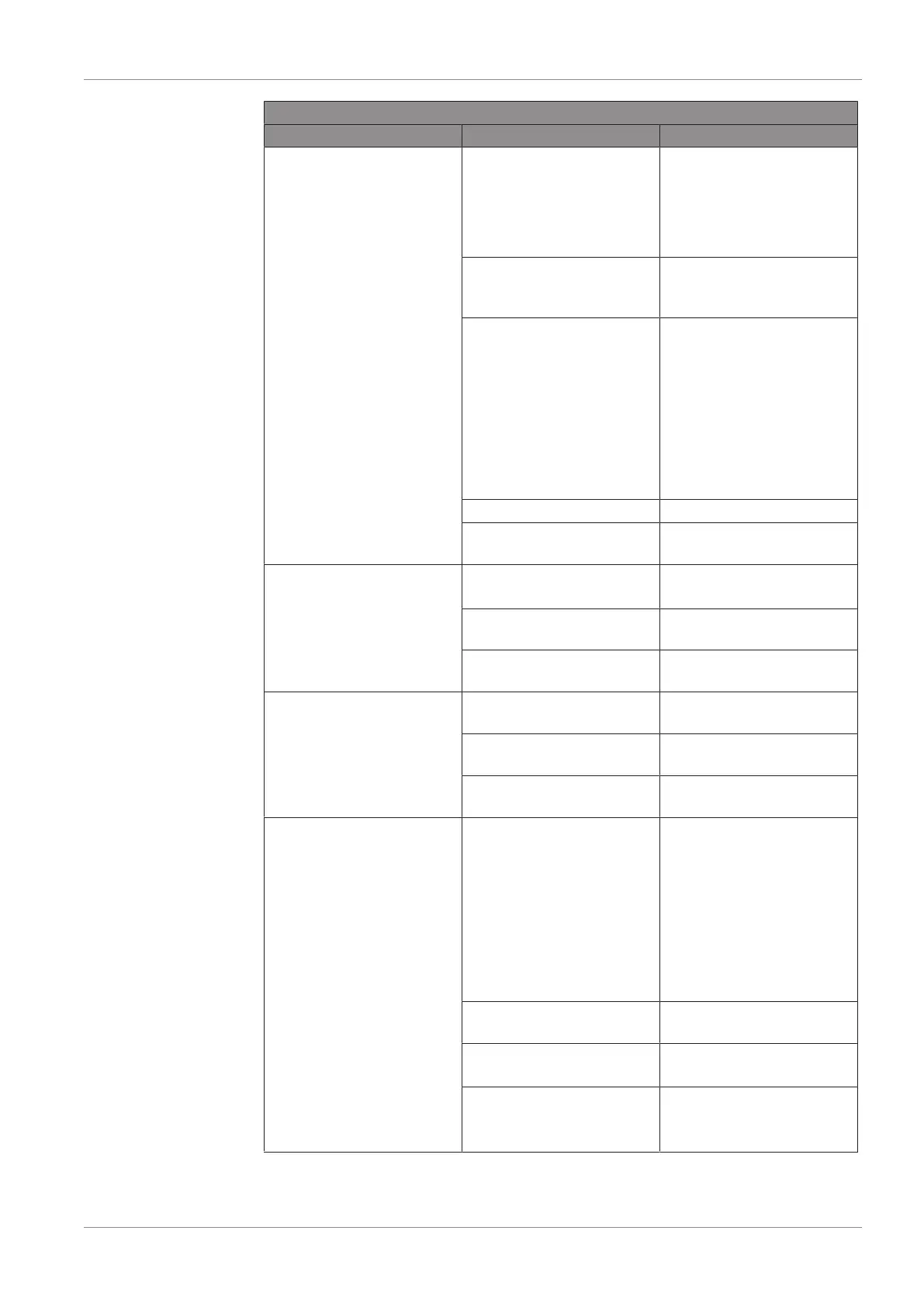

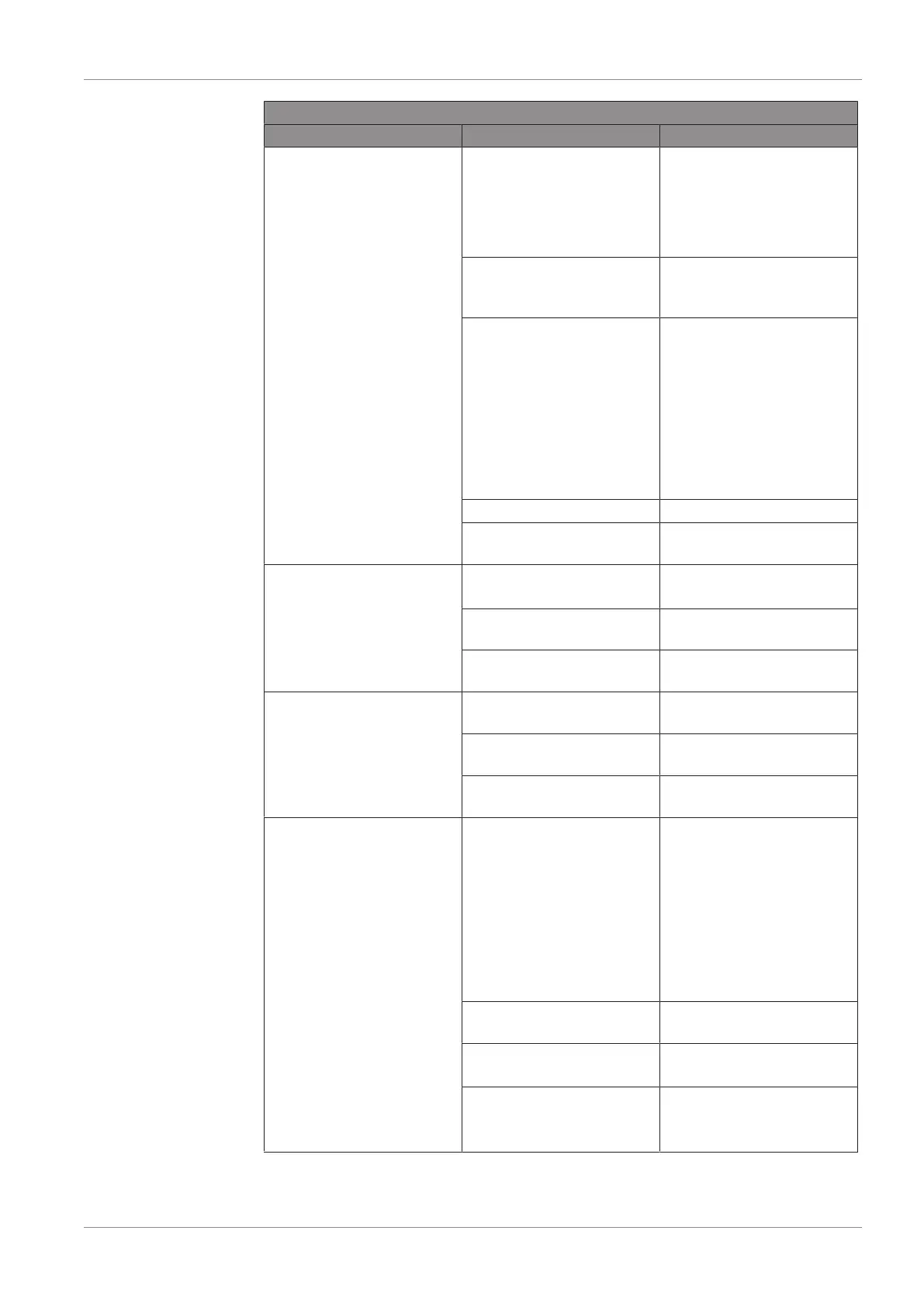

Table 1

Problem Possible Cause Remedy

The machine does not start. The power indicator light

(PIL) is not activated.

No power signal.

The machine is not supplied

with the correct voltage.

• Check the power supply

connection.

The machine is powered on

but the touchscreen or the

PLC does not run.

• Check the 24 V power

supply.

The machine has reached a

limit operating value.

• Identify and solve the

problem listed in the

menu “HOME” >

“WARNING/ALARM”,

see Warnings and Alarms

Thresholds [►51].

• Look up the related prob-

lem in the troubleshoot-

ing table 2.

The motor is defective. • Replace the motor.

The coupling (CPL) is de-

fective.

• Replace the coupling

(CPL).

The machine does not reach

the usual pressure on the

suction connection.

Oil level too low. • Top up oil,

see Filling Oil [►25].

The inlet filter cartridge (IF)

is partially clogged.

• Replace the inlet filter

cartridge (IF).

Internal parts are worn or

damaged.

• Repair the machine (con-

tact Busch).

The machine runs very nois-

ily.

Worn coupling (CPL). • Replace the coupling

(CPL).

Stuck vanes. • Repair the machine (con-

tact Busch).

Defective bearings. • Repair the machine (con-

tact Busch).

The machine runs too hot. Insufficient cooling. • Remove dust and dirt

from the machine.

• Standard air-cooled va-

cuum pump: check the

heat exchanger (AHE).

• Water-cooled vacuum

pump: check the water

heat exchanger (WHE)

and the water filter (WF).

Ambient temperature too

high.

• Observe the permitted

ambient temperature.

Oil level too low. • Top up oil,

see Filling Oil [►25].

The exhaust filters (EF) are

partially clogged.

• Replace the exhaust filters

(EF), see Exhaust Filter

Change [►58].

Loading...

Loading...