Maintenance

- 29 -

7. Maintenance

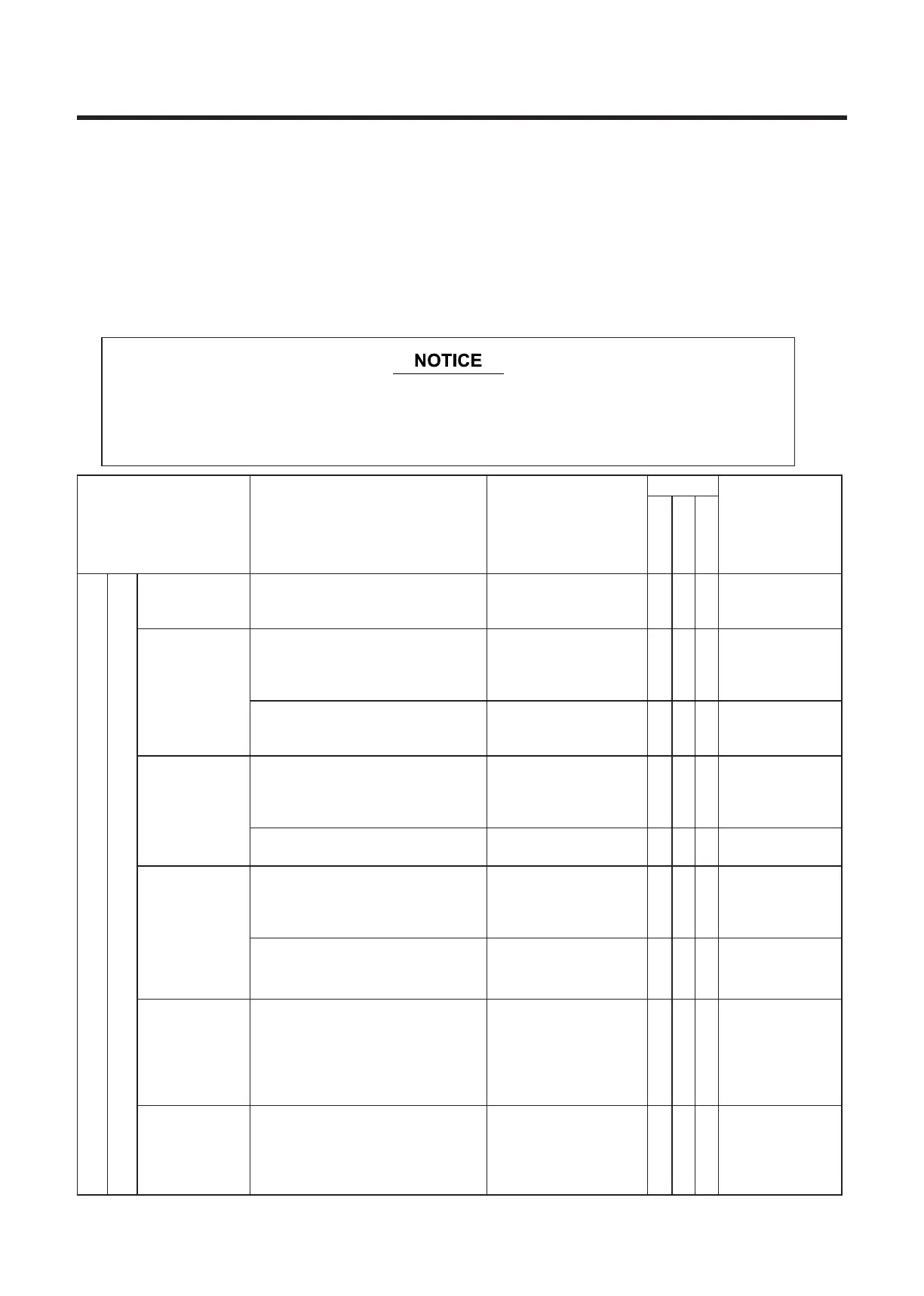

* The chart below includes inspections which require technical knowledge or

special tools and measuring instruments. For difficult inspections, consult the

dealer or a CANYCOM service center.

Maintenance

Item Action Acceptable condition

Timing

Remarks

Per-operation

Monthly

Yearly

Engine

Body

Starting

* Check if engine starts

smoothly and makes

abnormal noise.

Smooth start.

No abnormal noise.

○ ○ ○

Engine speed

* Check if engine speed is

proper at idling and unloaded

maximum speed. Check for

smooth operation.

Proper engine

speed. Smooth and

continuous engine

operation.

○ ○

Please

contact your

CANYCOM

distributor

* Accelerate engine and check

for axle lever drag, engine

stall, and knocking.

No drag, engine stall,

or knocking. ○ ○ ○

Exhaust

* After warming up engine, run

engine from idling to high

speed and check exhaust gas

color and noise.

Normal exhaust gas

color / noise.

○ ○ ○

* Check for gas leak from

muffler, exhaust pipe, etc.

No gas leak.

○ ○

Air cleaner

* Check case for cracks and

deformation, looseness at lid

or connecting pipe.

No cracks or

deformation in case.

No looseness at lid

and pipe.

○ ○

* Check urethane foam paper

element for contamination

and damage.

No severe dirt.

No damage. ○ ○ ○

Cleaning /

Replacement:

(See Page 40)

Tightening

* Check cylinder head and

manifold retaining bolts / nuts

for looseness.

* This check is not necessary if

no gas or water leak is found

at these areas.

No looseness.

○

Valve

clearance

* Check valve clearance.

* This check is not necessary

if no valve-derived abnormal

noise is heard and the engine

operates smoothly.

Proper clearance.

○

Please

contact your

CANYCOM

distributor

7.1 Periodic Inspection Table

* Performing periodic proper inspections and maintenance will improve machine performance,

increase safety, and may help prevent accidents and breakdowns. Perform regular inspections

according to the chart below.

* The regular inspection schedule includes yearly and monthly inspections, and daily

pre-operation checks.

Loading...

Loading...