10

MECHANICAL

Joint Sealant

Proper joint assemble is essential for a safe installation. Follow these instructions exactly as

written Check severeness of joints upon completion of assembly.

The joint sealant used to seal all joint assemblies is 3M Fire Barrier 2000+ Silicone Sealant. This sealant is

a ready-to-use, gun-grade, one-component silicone elastomer that cures upon exposure to atmospheric

humidity to form a flexible seal. 3M Fire Barrier 2000+ Silicone Sealant, when installed properly, will control

the spread of a fire before, during and after exposure to open flames. It will stop the spread of noxious gas,

smoke and water, and maintain the integrity of fire rated assemblies and construction. All grease ducts

must be liquid tight per NFPA 96. Model 2R Type HT chimney used in positive pressure applications must

be liquid tight per UL103 and UL103HT listing. Model 2R Type HT chimney used in neutral or negative

pressure applications does not require joints to be sealed with the 3M Fire Barrier 2000+ Silicone Sealant

per the listing report. When Model 2R Type HT chimney is used in neutral or negative pressure

applications, the system does not require the joints to be sealed; it is recommended for commercial

cooking appliances where grease is present.

NO SEALANT SUBSTITUTES MAY BE USED.

Sealant Features

1. Superior adhesion.

2. Capable of withstanding 2000°F + temperatures.

3. Class 25 sealant, per ASTM C920.

4. Re-enterable/repairable.

5. Provides up to 4-hours fire-rating.

6. Cures upon exposure to atmospheric humidity.

7. Working time 30 minutes.

8. Full cure time: 14 to 21 days.

9. The duct/chimney system can be placed in operation 7 days after installation, prior to full cure.

10. Applied with a standard caulk gun.

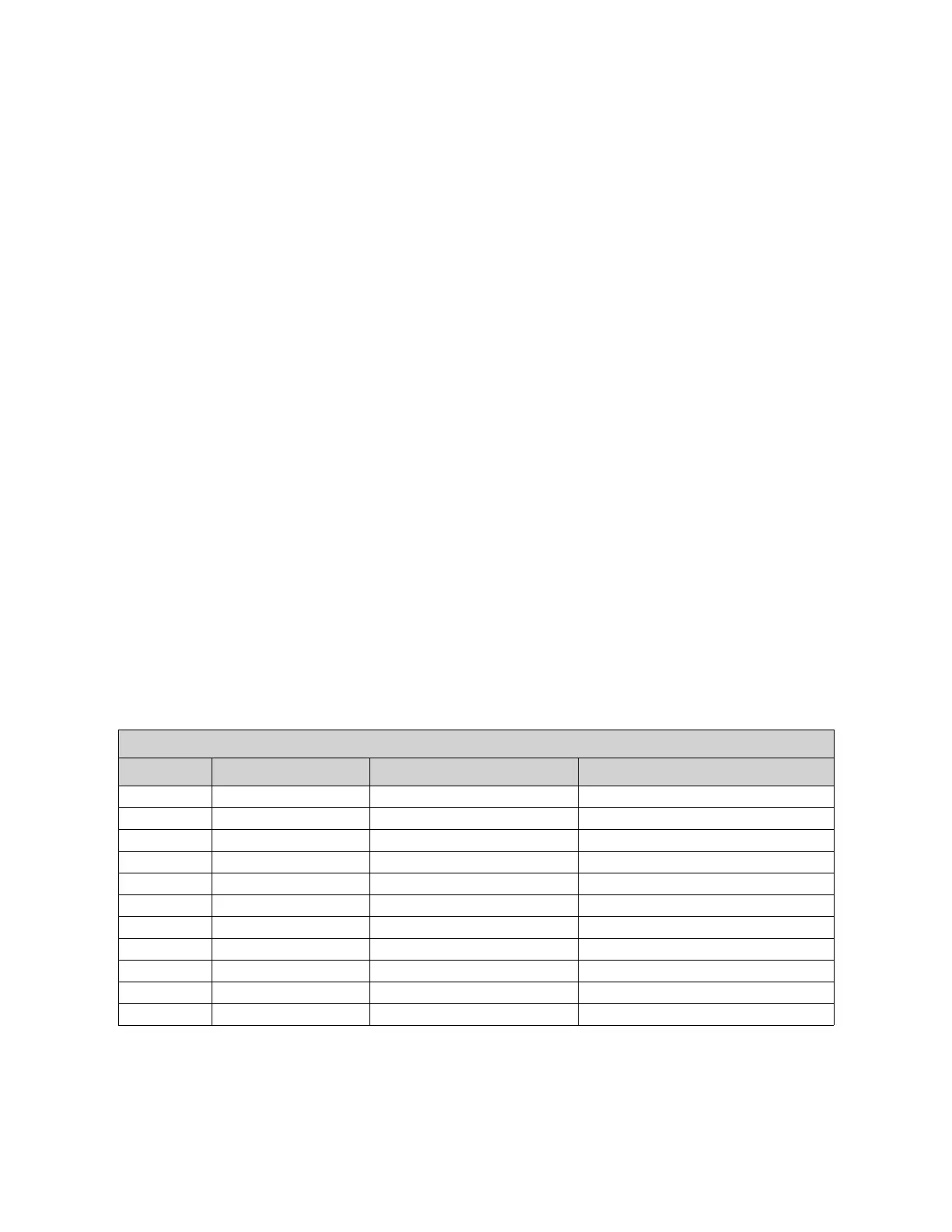

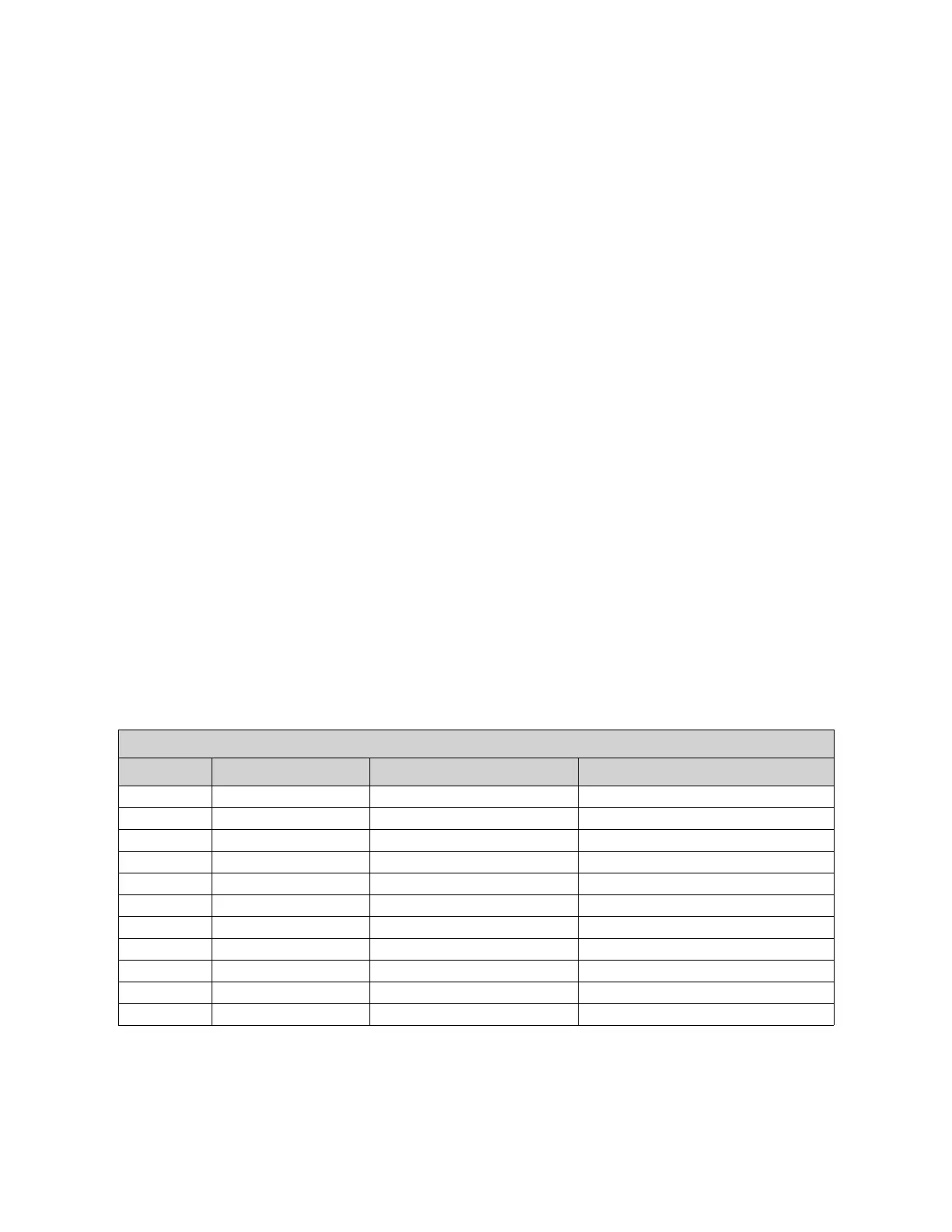

Table 2 - Sealant Usage Chart

3M Fire Barrier 2000 Plus Usage

Diameter Duct Perimeter Feet Average Feet Per Tube Number of Joints Per Tube

8” 2.16 30 7

10” 2.68 30 6

12” 3.21 30 5

14” 3.73 30 4

16” 4.25 30 3.5

18” 4.78 30 3

20” 5.30 30 3

22” 5.83 30 2.5

24” 6.35 30 2.5

30” 7.98 30 1.5

36” 9.55 30 1

Loading...

Loading...