25

ENG

“FCR3 three-phase controller” +030222150 - rel. 1.3 - 12.01.2021

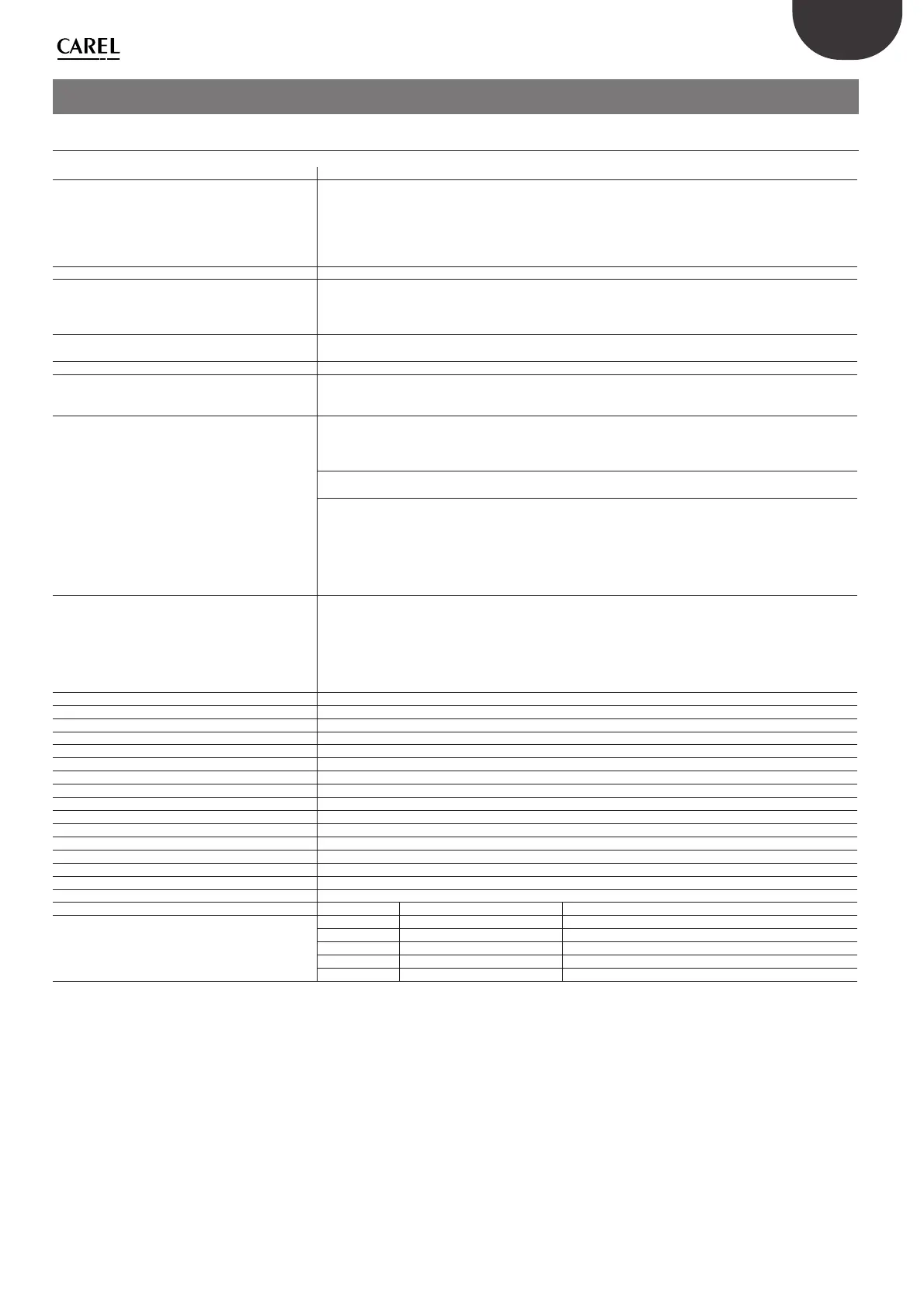

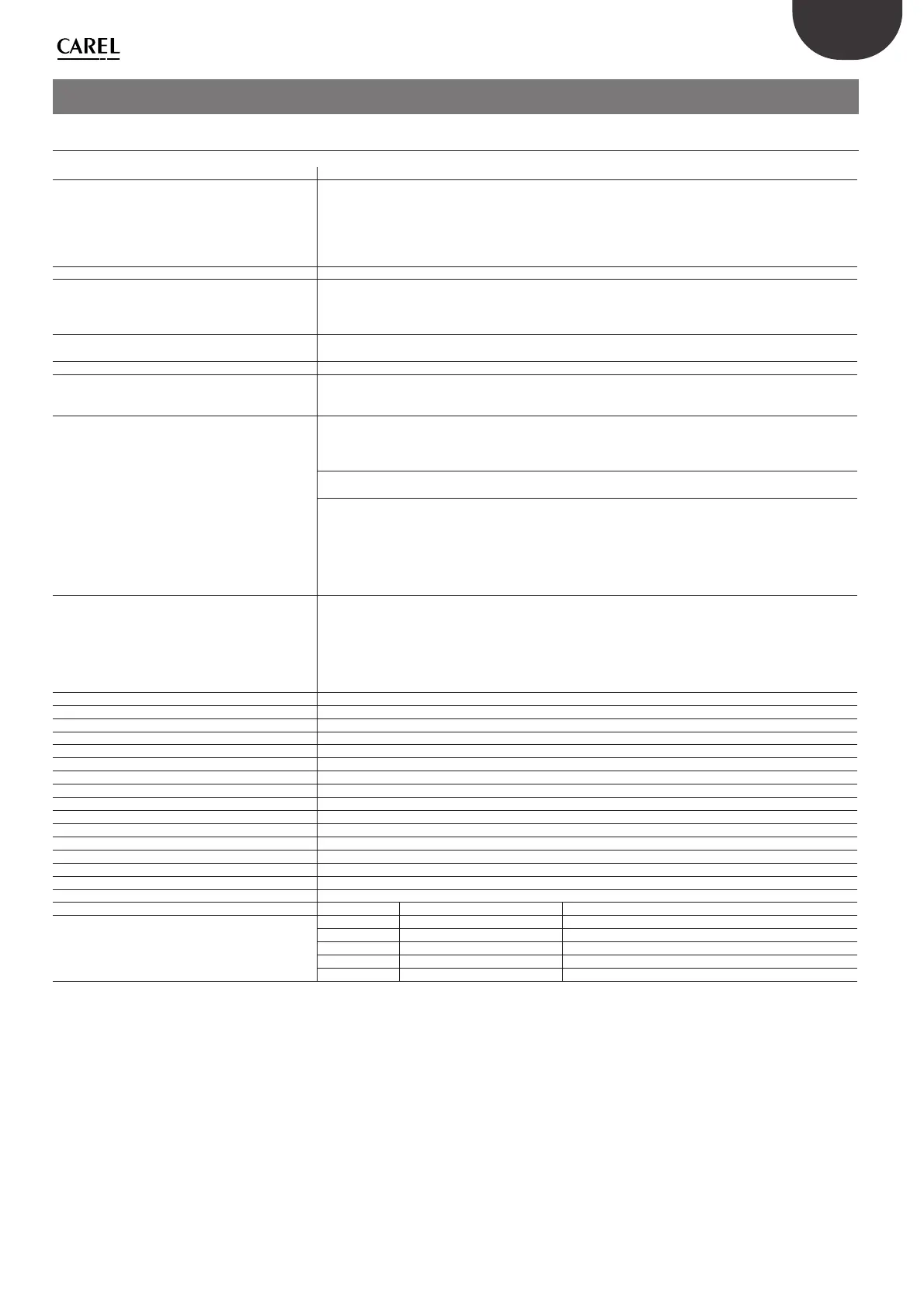

10. TECHNICAL SPECIFICATIONS

10.1 Electrical specifi cations, FCR3 series

Power supply 400Vac three-phase, -15% +10% 50/60 Hz

Analogue outputs

1 phase control 0-400 Vac three-phase: Max current:

6A FCR3064020

9A FCR3094040 two parallel outputs

12A FCR3124020

20A FCR3204020

40A FCR3404020

Digital outputs 1 SPDT output - 5 A 250 Vac – protected by varistor

Analogue inputs

1 analogue input, con gurable as

Input 0/10 V (input impedance 20 KΩ)

Input 0/5 V (PWM) - input impedance 20 KΩ

Input 0-20 mA (input impedance 250 KΩ)

Digital inputs

2 inputs for voltage-free contact in series

typical voltage 5 V with contact open, typical current 5 mA with contact closed.

Serial connection RS485 - ModBus supervisor protocol; baud rate 9600/19200/48400; max. length 1 km with shielded cable

Light signals

Green LED - power

Rossi LED - alarm

Blue LED - serial connection active

Controller setting

3 trimmers for manually setting:

- response delay (delay)

- minimum speed (min)

- maximum speed (max)

1 set of 8 dipswitches:

- select device address

1 set of 8 dipswitches

- select type of controller settings

- select 0/10V-0/5V

- select V/I

- select power supply frequency (50/60)

- select control type (LIN/QUAD)

- select null input mode (MIN/CUTOFF)

Terminals and connectors

Power supply and analogue outputs:

Screw terminals for cable cross-section min. 2.5 mm2 max 4 mm2. (6-9-12-20 A)

- Screw terminals for cable cross-section min. 2.5 mm2 max 10 mm2. (40 A)

Signals/Inputs/Digital outputs:

- Screw terminals for cable cross-section max 2.5mm2.

4 pin JST connector for programming key

Terminal connector for serial connection

Operating conditions -20/+50°C, <90% RH non-condensing

Storage conditions -20/+70°C, <90% RH non-condensing

Ingress protection IP55

Environmental pollution 2

Protection against electric shock Class I

PTI of the insulating materials 250 V

Period of stress across the insulating parts Long

Type of action - disconnection 1Y

Heat and re resistance category Category D (UL94 – V0)

Overvoltage category Category II

Ageing characteristics 60,000 operating hours

No. of automatic operating cycles 100,000

Software class and structure Class A

Case Metal heat sink (Al) with plastic case (110°C ball pressure test)

Dimensions See paragraph 10.3

Assembly Fasten using the brackets to panel, or wall mounting with 4 x 6 mm screws

Safety certi cation EN 60730-1 Safety FCR306****, FCR309,****, FCR312****,FCR320****, FCR340****

EMC certi cation

EN 55014-1 Emissions: household appliances FCR306****, FCR309,****, FCR312****

EN 55014-2 Immunity: household appliances FCR306****, FCR309,****, FCR312****

EN 61000-6-2 Immunity: industrial FCR306****, FCR309,****, FCR312****,FCR320****, FCR340****

EN 61000-6-3 Emissions: household FCR306****, FCR309,****, FCR312****

Immunity: household FCR320****, FCR340****

Tab. 10.a

Loading...

Loading...