24

ENG

“FCR3 three-phase controller” +030222150 - rel. 1.3 - 12.01.2021

9. SUPERVISION

Modbus protocol is supported on serial line V1.0 in slave mode (response

only following query from Master).

Speci cations

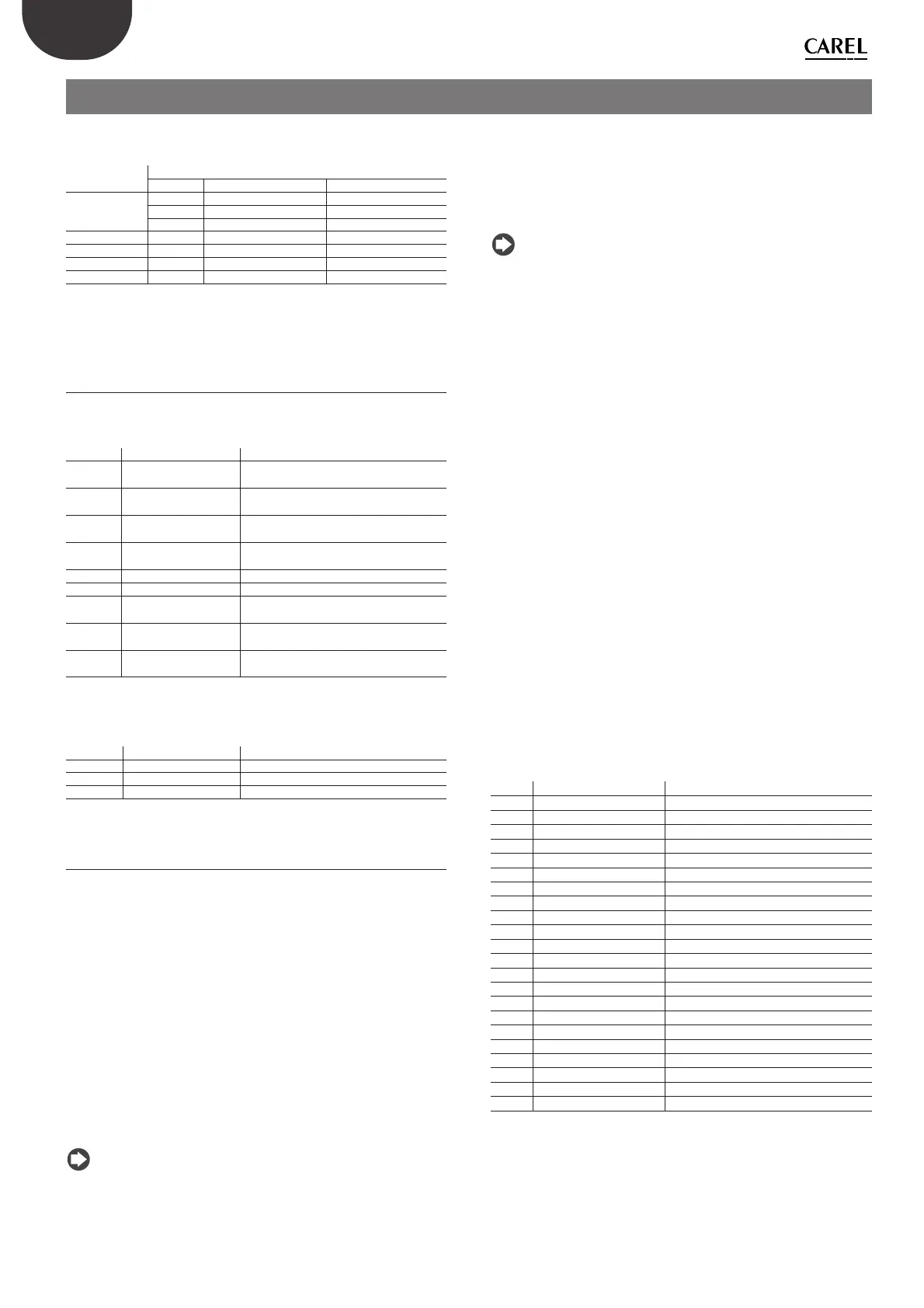

Value Dip S2.7/ BAUD1 Dip S2.8/ BAUD2

baud rate

9600 OFF OFF

19200 ON OFF

38400 OFF ON

start 1 bit

data 8 bit

parity None

stop 2 bit

Tab. 9.a

9.1 Modbus protocol

This is used to manage the connection to all devices and supervisory

systems that support Modbus on serial line V1.0 (specif. V1.1a). The

following table illustrates the currently supported function codes:

Code Short description Description

01 (0x01) Read Coils

Read from 1 to 16 consecutive digital

variables

02 (0x02) Read Discrete Inputs

Read from 1 to 16 consecutive digital

variables

03 (0x03) Read Holding Registers

Read from 1 to 16 analogue/integer

variables

04 (0x04) Read Input Registers

Read from 1 to 16 consecutive analogue/

integer variables

05 (0x05) Write Single Coil Write 1 digital variable

06 (0x06) Write Single Register Write 1 analogue or integer variable

15 (0x0F) Write Multiple Coils

Write from 1 to 16 consecutive digital

variables

16 (0x10) Write Multiple Registers

Write from 1 to 16 consecutive analogue/

integer variables

17 (0x11) Report Slave ID

Return the MAC identi er and controller

status

Tab. 9.b

The following table illustrates the currently supported Modbus

exceptions:

Code Short description Description

1 Illegal function Function code not supported

2 Illegal data address Invalid Slave address

3 Illegal data value Slave data not valid

Tab. 9.c

9.1.1 Description of the supported function codes

• 0x01 Read Coils

• 0x02 Read Discrete Inputs

Return from 1 to 16 consecutive digital variables.

The slave responds with an exception in the following cases:

EXCEPTION 2: Address of the rst requested variable > 16

Address of rst requested variable + number of variables requested > 16

EXCEPTION 3: Number of variables requested > 16

• 0x03 Read Holding Registers

• 0x04 Read Input Registers

Return from 1 to 16 consecutive analogue or integer variables

The slave responds with an exception in the following cases:

EXCEPTION 2: Address of the rst requested variable >16

Address of rst requested variable + number of variables requested >16

EXCEPTION 3: Number of variables requested > 16

Note: the maximum number of 32 transmittable integer variables

is determined by the maximum size of the transmission bu er.

• 0x05 Write Single Coil

Write a digital variable on the Slave to ON or OFF.

The slave responds with an exception in the following cases:

EXCEPTION 2: Write variable address > 16;

EXCEPTION 3: Value to write contained in the Modbus packet other than

0x0000 (OFF) or 0xFF00 (ON)

Note: a Write Single Coil packet sent from a Master compliant

with the Modbus protocol should NEVER generate this exception;

• 0x06 Write Single Register

Write an analogue or integer variable to the Slave.

The slave responds with an exception in the following cases:

EXCEPTION 2: Write variable address not between 1-16

EXCEPTION 3: Data not acceptable by the SLAVE

• 0x0F Write Multiple Coils

Write from 1 to 16 consecutive digital variables to the Slave.

The slave responds with an exception in the following cases:

EXCEPTION 2: Address of rst variable to write >16

Address of rst variable to write + number of variables requested >16

EXCEPTION 3: Number of variables to write > 16

• 0x10 Write Multiple Regsiters

Write from 1 to 16 consecutive analogue or integer variables to the Slave.

The slave responds with an exception in the following cases:

EXCEPTION 2: Address of rst variable to write > 16

Address of rst variable to write + number of variables requested > 16

EXCEPTION 3: Number of variables to write > 16

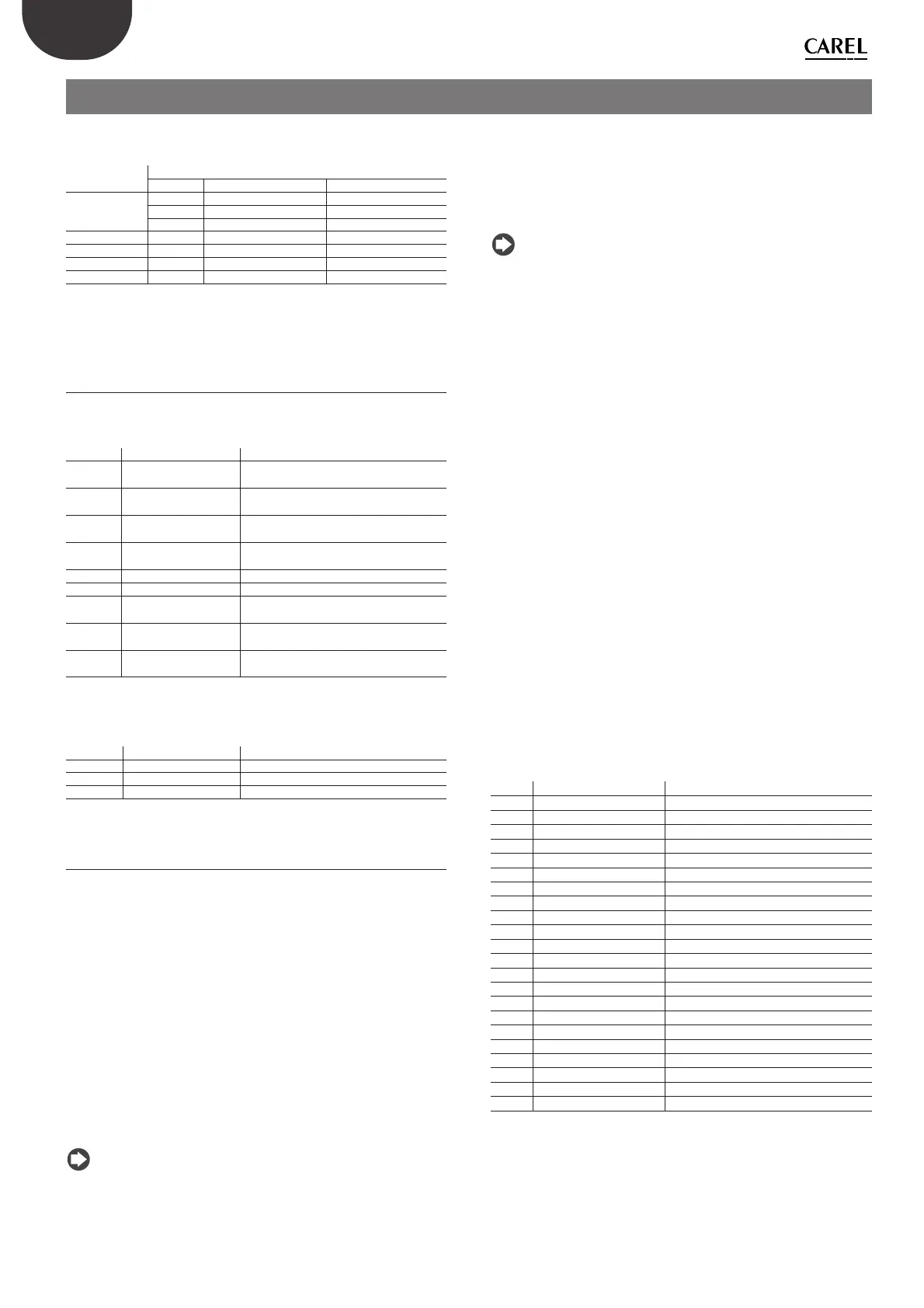

• 0x11 Report Slave ID

Return the unit code (MAC parameter), the status of the controller (ON/

OFF) and the FW release (REL parameter).

The parameters returned are shown in detail in Table 9.d

The Slave does not respond with an exception in any circumstances.

1 Address

2 Function = 17 = 0x11 17 = 0x11

3 N° Byte 18

4 Slave ID 0

5 Device state 0=OFF / 255= ON

6 MACH 0x01

7 MACL 0x37

8 RELH 00

9 RELL 00

10 HWH 00

11 HWL 00

12 Prot 0

13 Prot 0

14 MAX VARIABLE 0x10

15 MAX COIL INPUT 0x10

16 OPTION CODE 0

17 OPTION CODE 0

18 TV 23/40

19 TI 06/09/12/20/40

20 Customer 0

21 Customer 0

22 CRCH xx

23 CRCL Xx

Tab. 9.d

Loading...

Loading...