141

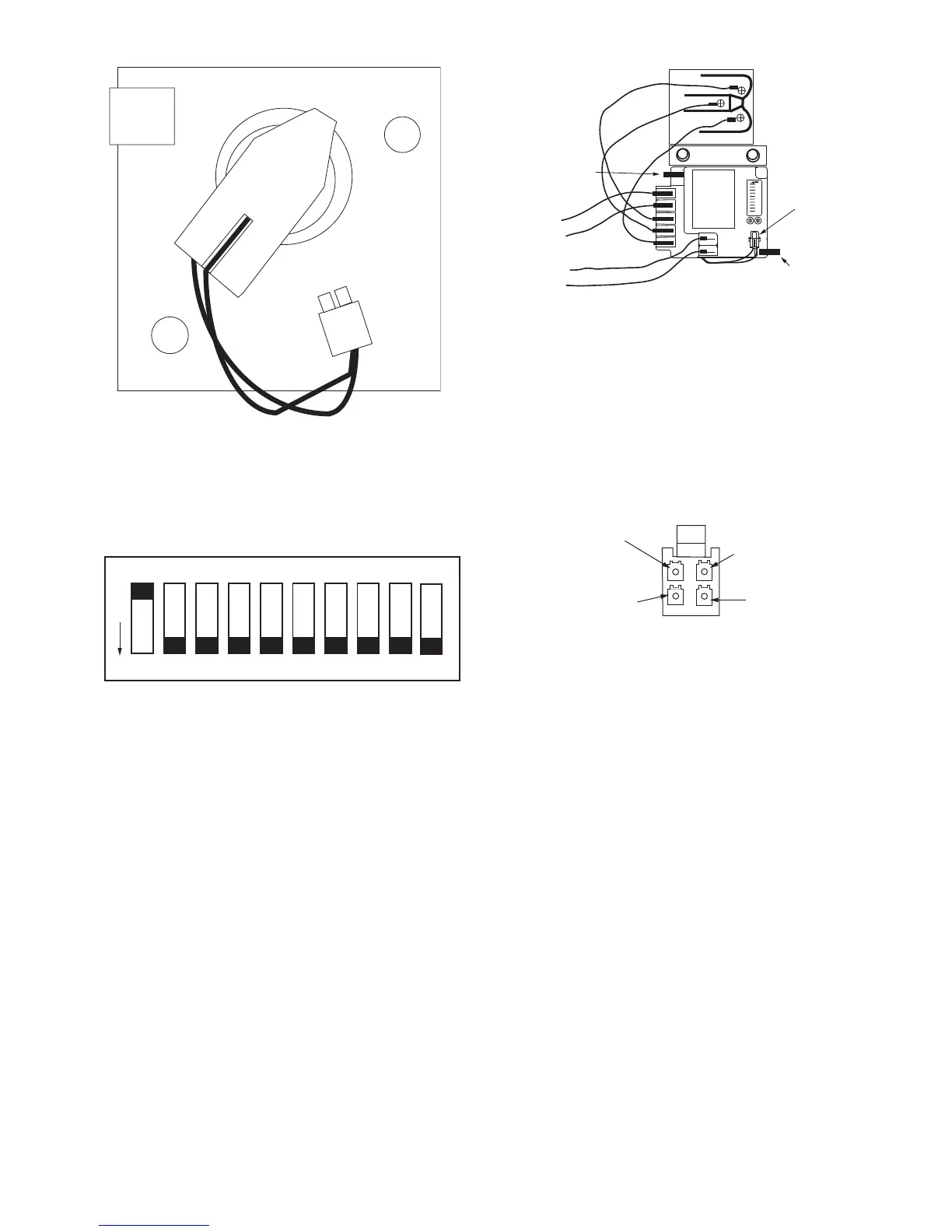

2. Review the DIP switch settings on the CoreSense mod-

ule. DIP switch no. 1 should be ON (up position) and all

other DIP switches should be OFF (down position). See

Fig. 163.

3. Install the CoreSense module in the compressor terminal

box as shown in Fig. 164, with the tabs holding the

module in place. Route the thermistor wire harness as

shown and plug the harness into the 2x2 socket on the

CoreSense module.

4. Connect the previously labeled M1, M2, T1, and T2

wires to the appropriate terminals on the CoreSense mod-

ule.

5. Connect the L1, L2, and L3 phase sensing wires to the

L1, L2, and L3 compressor terminal block connections.

See the compressor terminal cover diagram for identica-

tion of the L1, L2, and L3 terminal block connections.

6. Double-check the installation and make sure all connec-

tions are secure. Install the compressor terminal cover.

The CoreSense retrofit is complete and the system can be

put back into service.

CoreSense Communications Module Troubleshooting —

Copeland models with a "TE" in the electrical code (i.e.,

ZP182KCETED) have a motor overload system that consists

of an external CoreSense communication electronic control

module.

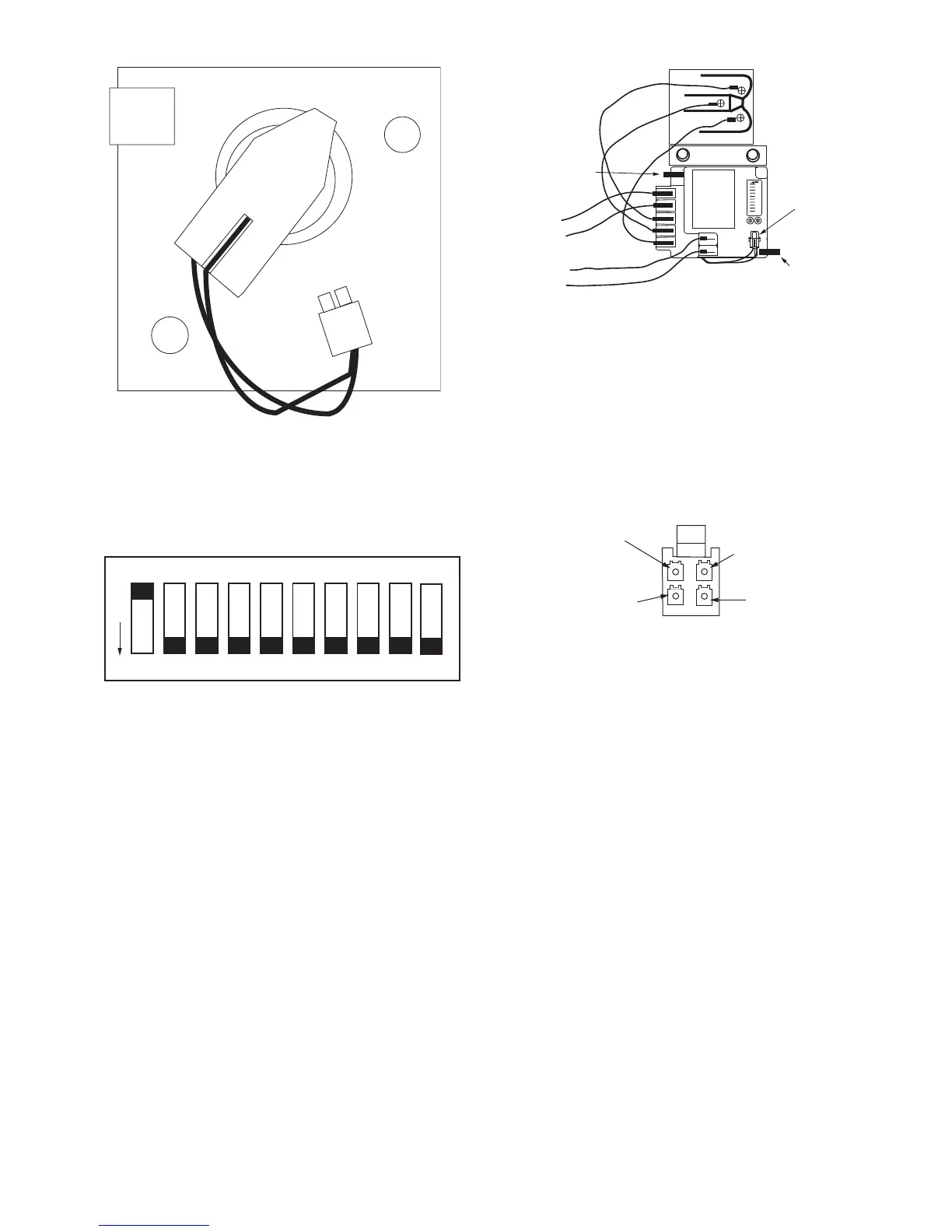

Motor thermistors are connected to the CoreSense commu-

nication module via a 2x2 plug (Fig. 165).

The CoreSense communications module has field configurable

DIP switches for addressing and configuring the module. The

DIP switches should be addressed as shown in Table 63.

The CoreSense communication module has a green and a

red light-emitting diode (LED). A solid green LED indicates

the module is powered and operation is normal. A solid red

LED indicates an internal problem with the module. If a solid

red LED is encountered, power down the module (interrupt the

T1-T2 power) for 30 seconds to reboot the module. If a solid

red LED is persistent, change the CoreSense module.

INSTALL IN THIS

ORIENTATION

A38-7311

Fig. 162 — Compressor Motor Sensor Harness

Installation

ROCKER DOWN

O

F

F

ON

OFF OFF OFF OFF OFF OFF OFF

OFF

123456789

OFF

10

A38-7812

Fig. 163 — CoreSense Communication DIP

Switch Settings for Kriwan Retrofit

1 2 3 4 5 6 7 8 9 10

T2 T1

L3

L2L1

RED

BLACK

WHITE

BLUE

HOLDING

TA B

HOLDING

TA B

THERMISTOR WIRE

HARNESS PLUGGED

INTO 2X2 SOCKET

BLACK

WHITE

A38-7313

Fig. 164 — CoreSense Communication Module

Mounting

MOTOR

PTC

CIRCUIT

SCROLL

NTC CIRCUIT

(NOT USED)

FOR FUTURE

USE

COMMON

CONNECTION

a38-7308

Fig. 165 — CoreSense Communications

Motor Thermistor Plug

Loading...

Loading...