1. Disconnect power and air from the machine.

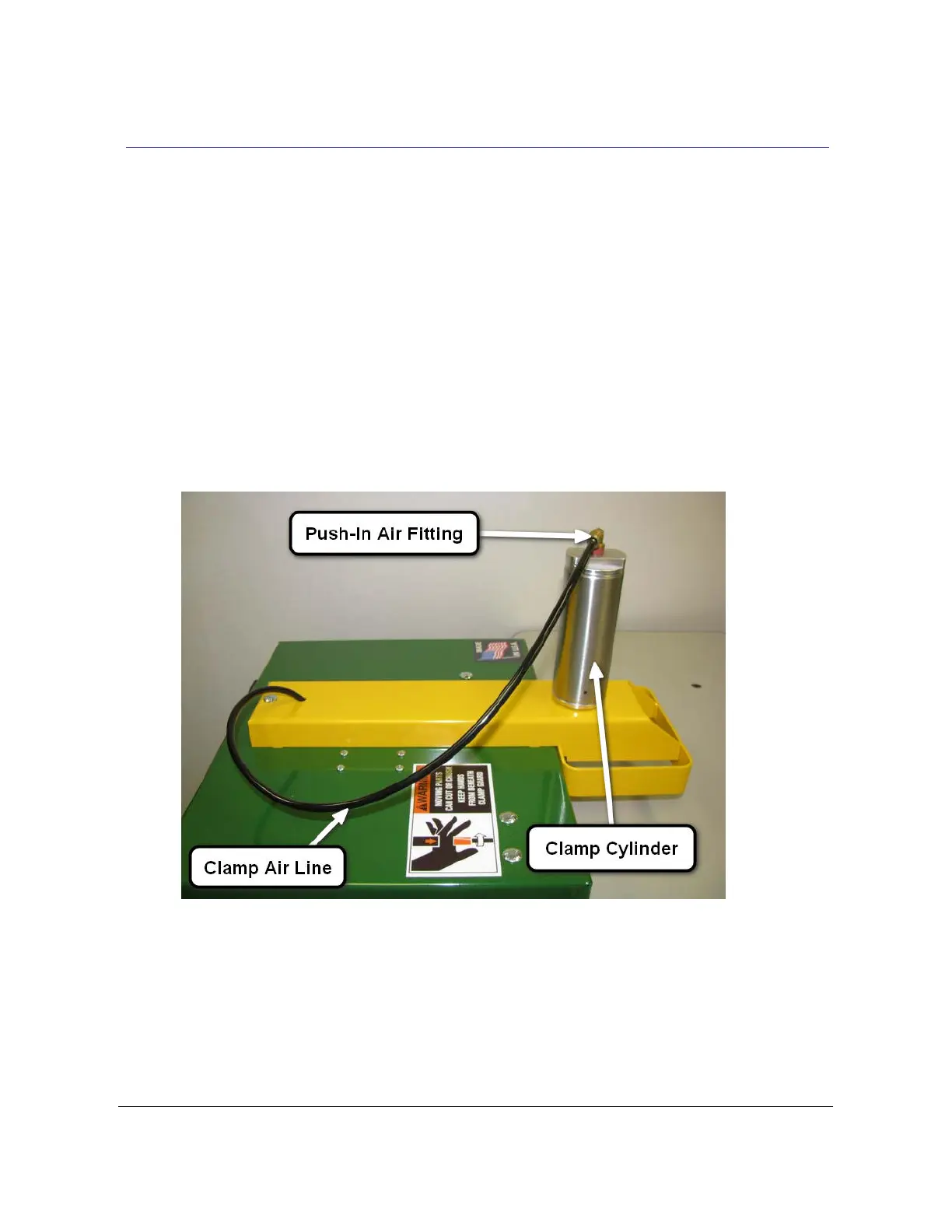

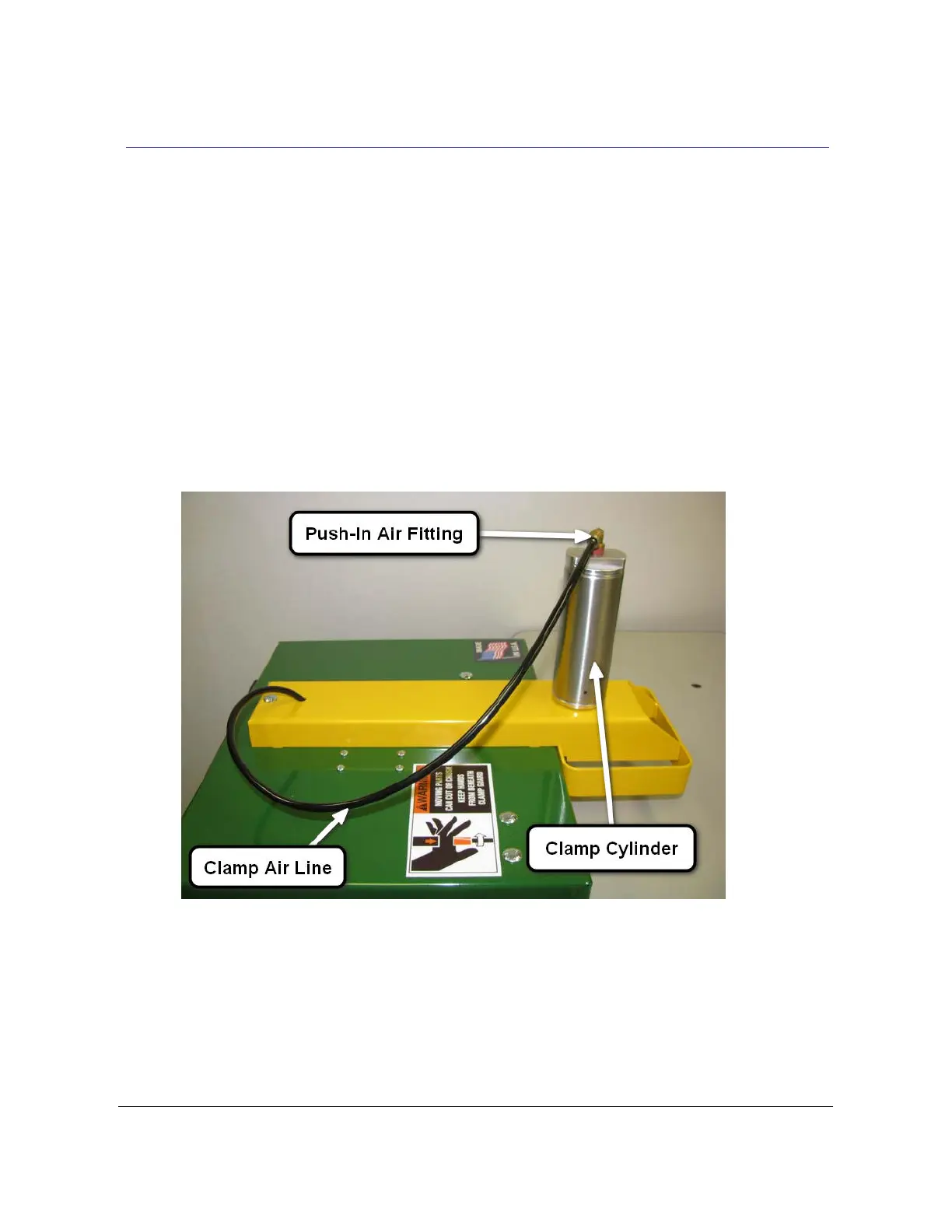

2. Disconnect the air line from the “push in” fitting of the Clamp Cylinder.

3. Connect an external air supply directly to the “push in” air fitting. See Fig 5a.

Fig 5a

4. The Clamp Foot should fully extend quickly. Remove the external air supply and the

Clamp Foot should fully retract quickly.

5. If both clamp actions are smooth and quick the Clamp Cylinder is operating properly.

Continue troubleshooting the Clamp Cylinder Air Line, the Exhaust Muffler on the Clamp

Solenoid and the Clamp Solenoid. See Fig 5b and 5c.

5.4 Clamp Cylinder Check 21.12

If the Clamp Cylinder clamps or retracts slowly it is having trouble filling or exhausting, or it may

be faulty. If the clamp operates normally with an external air supply, look for a crimp in the

black ¼” air line from the Clamp Cylinder to the Clamp Solenoid.

5.4.1 TROUBLESHOOTING STEPS:

TSM-21 Diagnostic Manual Parker/Humphrey Solenoids

Loading...

Loading...