9

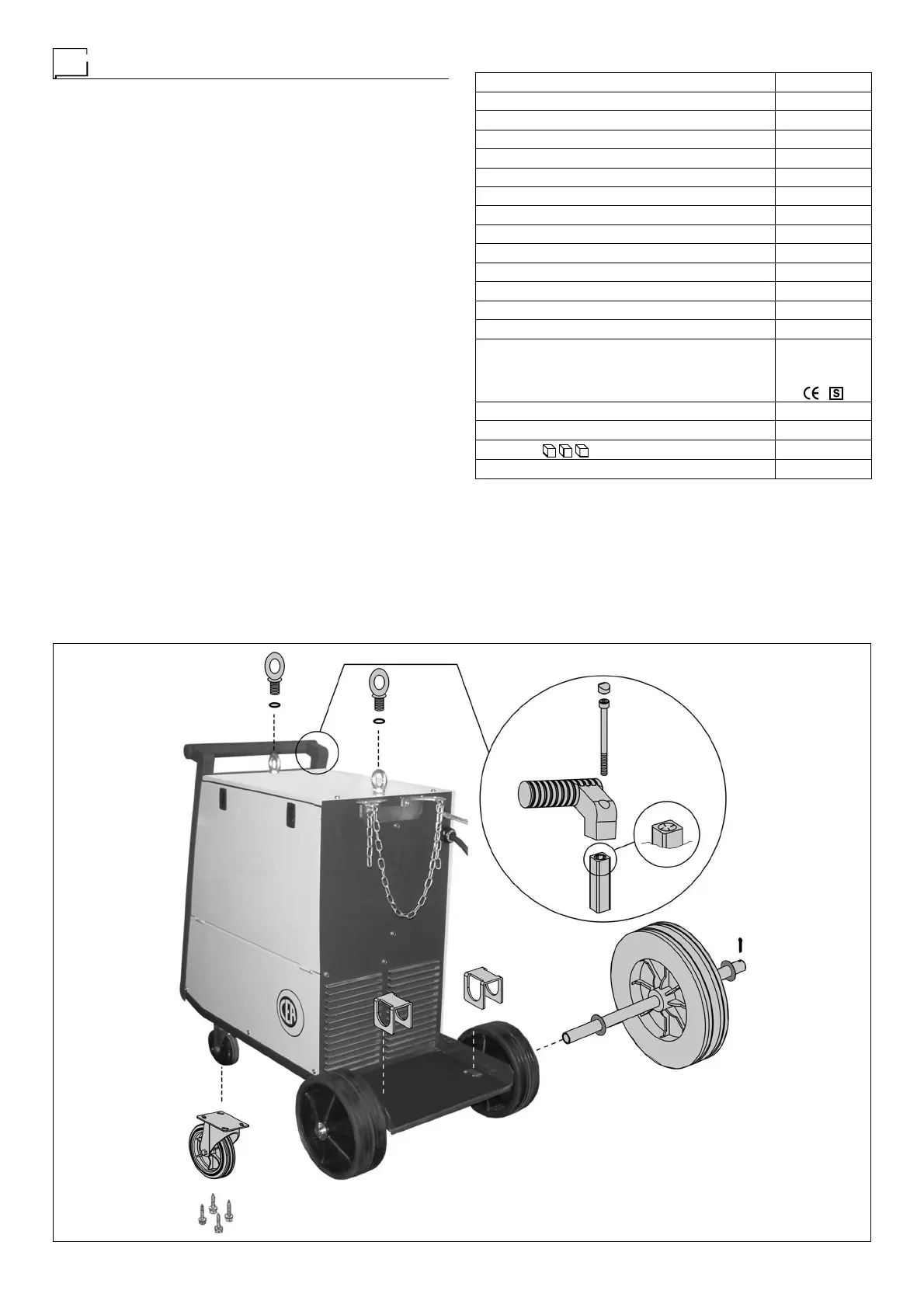

FIG. A

2000H917

Assembling the welding machine

The standard composition of this welding installation consists

of:

• COMPACT 364 generator.

• Ground lead (optional).

The supply also includes the rear wheels for moving the weld-

er, a chain for securing the gas cylinder to the cylinder trolley,

a handle for moving the machine by hand and two eyebolts for

lifting the machine.

Perform the following operations before using the machine:

•

Remove the welding generator and all relative accessories

and components from the packaging.

•

Check that the welding apparatus is in good condition, other-

wise immediately inform the retailer or distributor.

•

Check that all ventilation grilles are open and that no objects

obstruct the free passage of air.

• Assemble the machine as shown in figure A.

Table 1

Model COMPACT 364

Three-phase power supply 50/60 Hz V 230/400

Mains supply: Z

max

(*)

Power input @ I

2

Max kVA 17,3

Delayed fuse (I

2

@ 60%) A 25/20

Power factor / cosφ 0,96

Maximum efficiency degree 0,66

Open circuit voltage (max) V 18,5 ÷ 45

№ of switch positions 14

Current range A 45 ÷ 350

Duty cycle @ 100% (40°C) A 200

Duty cycle @ 60% (40°C) A 260

Duty cycle @ 35% (40°C) A 350

Wire diameter mm 0,6 ÷ 1,2

Standards

IEC 60974-1

IEC 60974-5

IEC 60974-10

Protection class IP 23 S

Insulation class H

Dimensions

mm 860-540-790

Weight kg 83

(*) IMPORTANT:

•

This plant meets the requirements laid down in the EN/IEC 61000-

3-12 standard on harmonic currents.

•

This system, tested according to EN/IEC 61000-3-3, meets the re-

quirements of EN/IEC 61000-3-11.

Loading...

Loading...