90

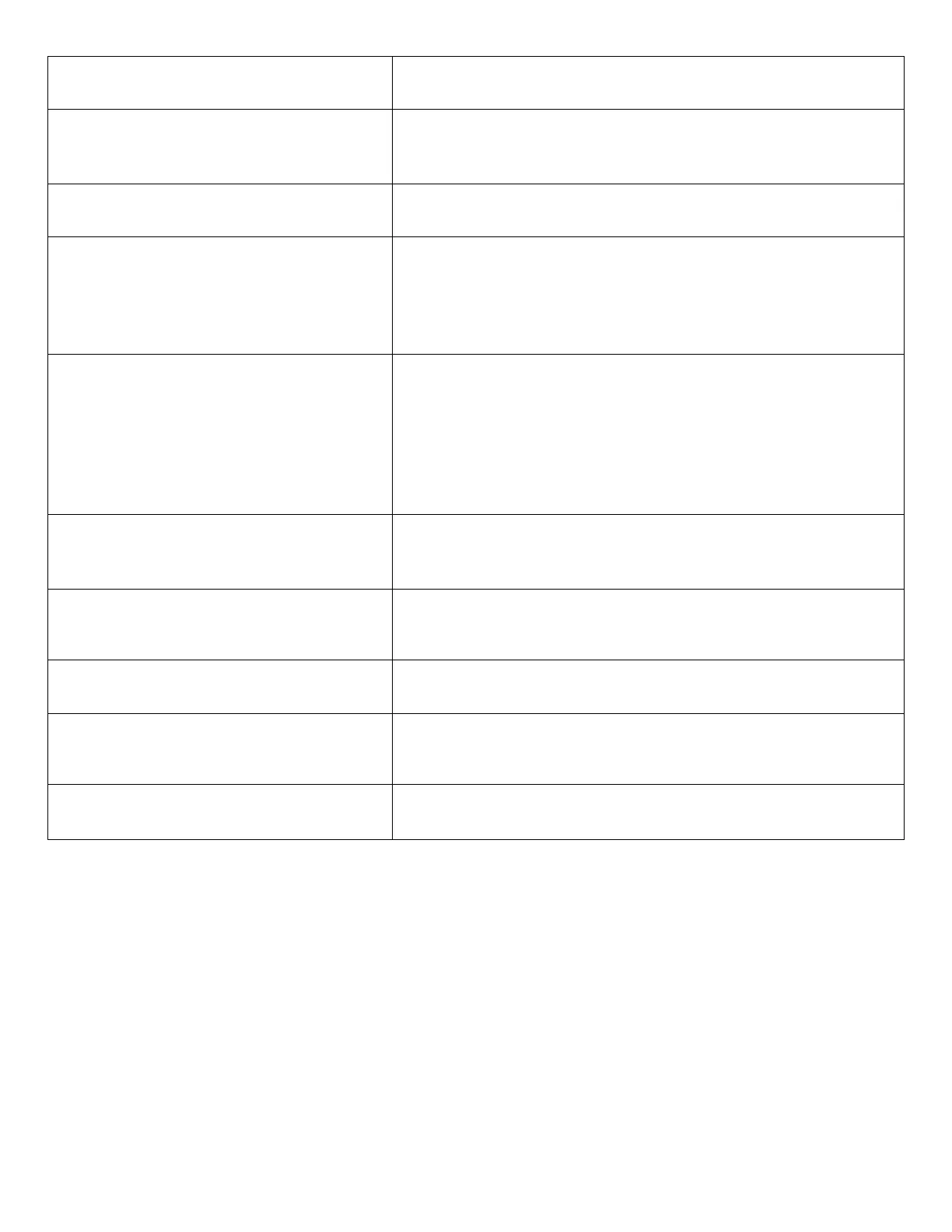

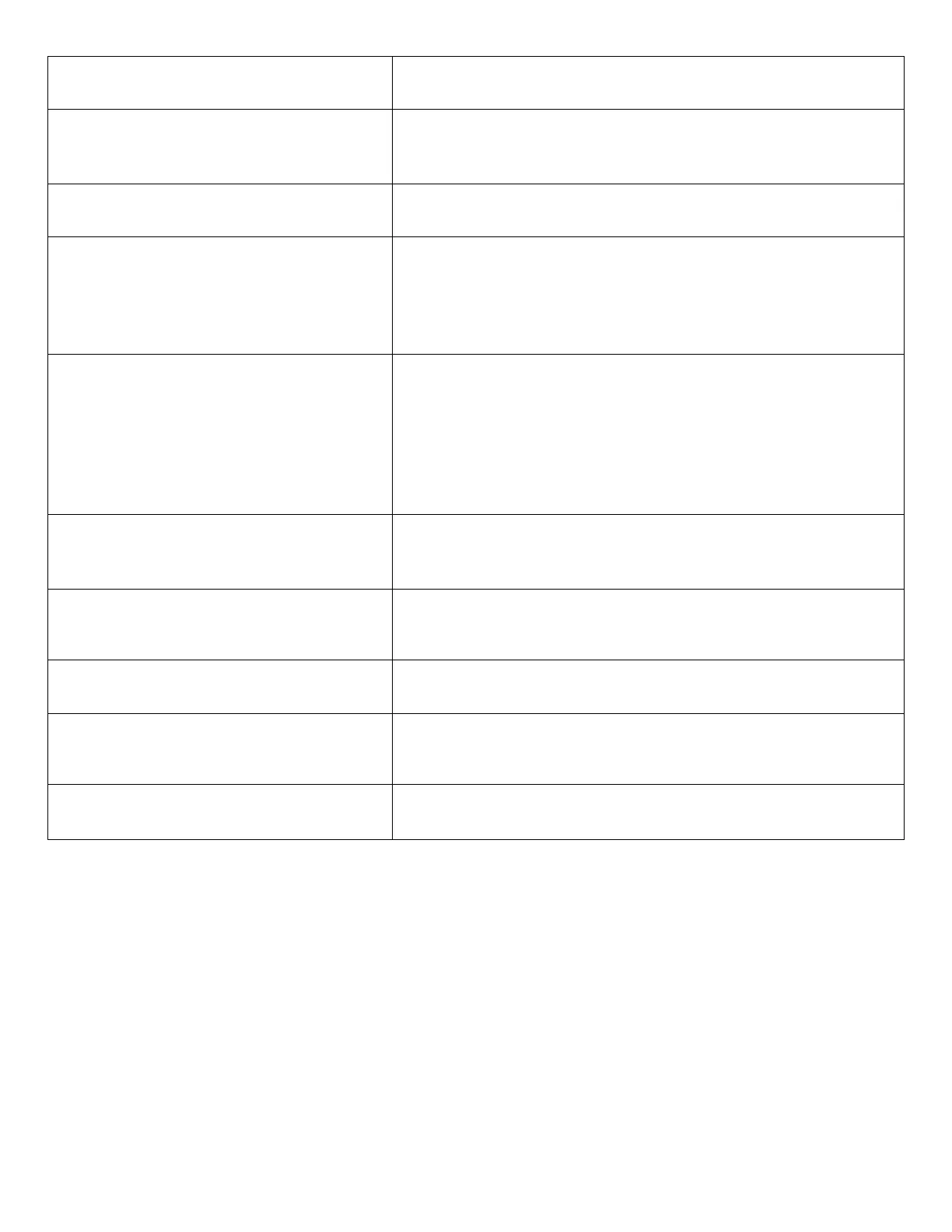

Microwave Leakage Improperly adjusted instrument door

Damaged instrument door

Inoperative Cavity Light

Faulty LED assembly

Loose connection(s)

Faulty connection(s)

Tangled Pressure Sensing Line Control vessel not positioned properly in turntable

Turntable not alternating

Vapors in Laboratory Loose drain valve

Leakage from vessel

Ruptured membrane

Vent hose to fume hood not installed

Faulty blower assembly

No Rise in Pressure in Control Vessel Leakage at vent fitting

Rupture membrane not installed

Thermowell loose in vessel

ESP-1500 Plus unattached or faulty

Sample does not absorb microwave energy

Liquid does not generate pressure upon heating

Vessels improperly torqued

No Rise in Temperature in Control

Vessel

Sample does not absorb microwave energy

Temperature probe inserted incorrectly

Temperature probe connected incorrectly

Ruptured Optional Vessel Membrane Excessive amount of reactive organic sample

Leakage from control vessel resulting in abnormal pressure

buildup in other vessels

Venting Relief Valve

Excessive amount of reactive organic compounds

Two-way valve in incorrect position

Loose Pressure Sensing Tube in

Control Vessel

Tubing not fully inserted and sealed into mating fitting with

ferrule nut

Closed microwave transparent valve

Instrument shuts down during test Fiber optic sensor malfunctions or stops operation

One or both IR sensors cease operation

Loading...

Loading...