chapter 7000

page 6

1,2 - 2,0 t A.C.

SERVICE MANUAL

Electric

036-0410-07

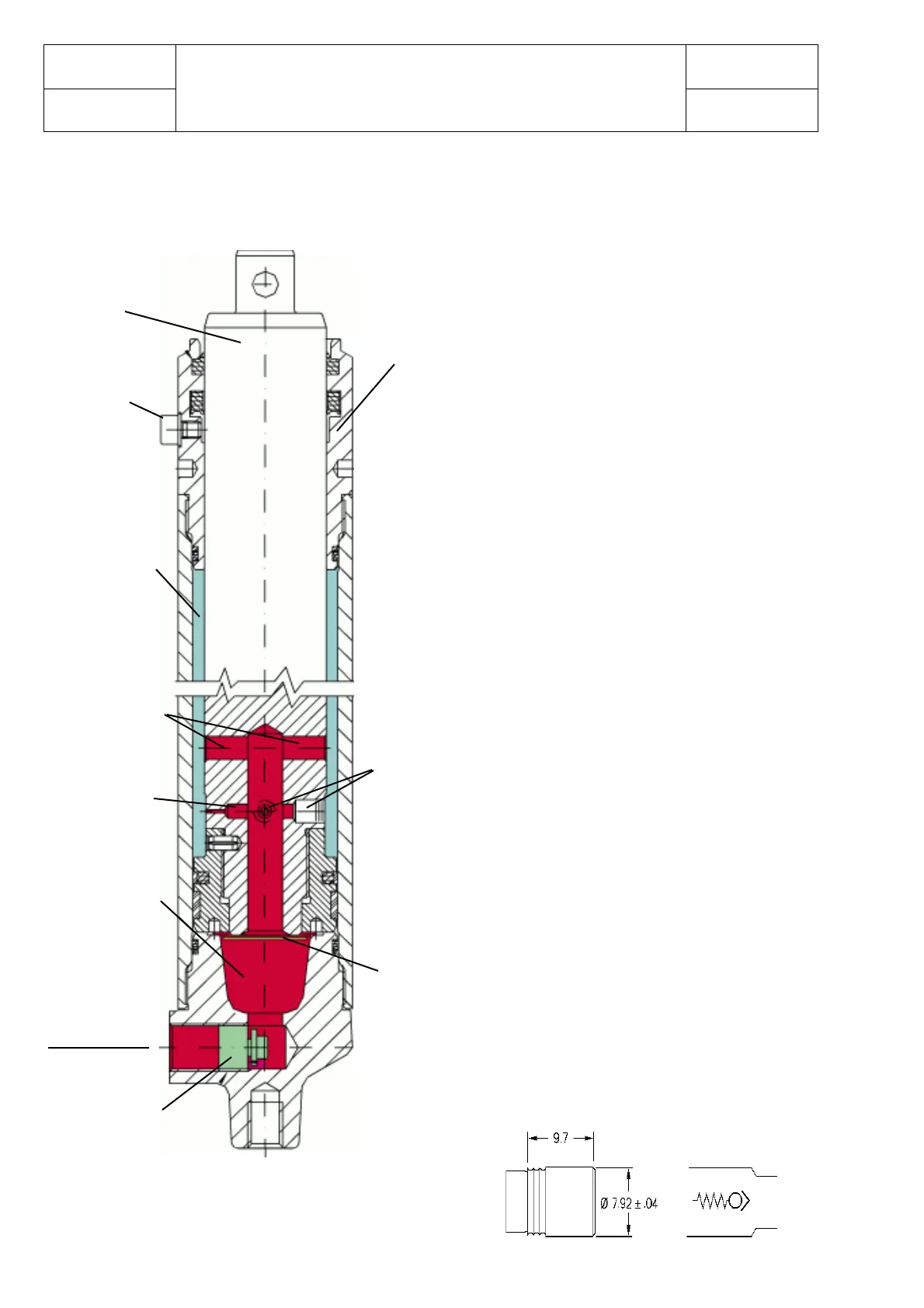

CENTRAL DISPLACEMENT CYLINDER WITH BRAKING EFFECT

ON THE LIFTING

The oil flows into the cylinder from the

“Oil inlet” when the control valve is

operated.

Flowing through channels 1, 2 and 3, it fills

chamber A until the inner oil pressure

exerts an upward force against the surface

C. The outward sliding of the rod is, thus,

set off. This movement is enacted by the

oil flow from chamber A to chamber B

through the above mentioned channels.

At the end of the expanding process

channels 1 and 2 are plugged by the cap.

Therefore, since the oil flowing between

the two chambers passes only through

channel 3, it has a lower capacity. The

outcome is a slowing-down or “Braking

effect”.

The downward sliding of the rod is

allowed by the opening of the “Oil inlet”

circuit, so that the oil can be retrieved

into the tank by means of the control

valve.

At the beginning of this phase chamber

A contains no oil. A more constant

filling is allowed by the two

unidirectional valves D and E that,

when open, permit avoiding jolts.

Once beyond the cap, the oil flow

between the two chambers passes

through channels 1 and 2, which are

now open.

Unidirectional

valves D-E

Rod

Bleeder

screw

Chamber A

Channels 1-2

Channels 3

Chamber B

Oil inlet

Safety valve

Surface C

Cap

>

Unidirectional

valves D-E

Loading...

Loading...