8.0 Maintenance Guide

24

8.1 Troubleshooting

DISCONNECT THE POWER AND LOCK IT OUT whenever working on

the machine unless the instructions specifically require the machine to be powered (see Power

Lockout Procedure, page 5). Some of the following tests may require the machine to be operational

for checking and adjusting. Be very careful that tools and other people are clear of moving parts, and

that the drill is not accidentally operated while adjustments are being made.

Whenever repairing hydraulic components, loosen connections slowly to

bleed off any trapped pressure.

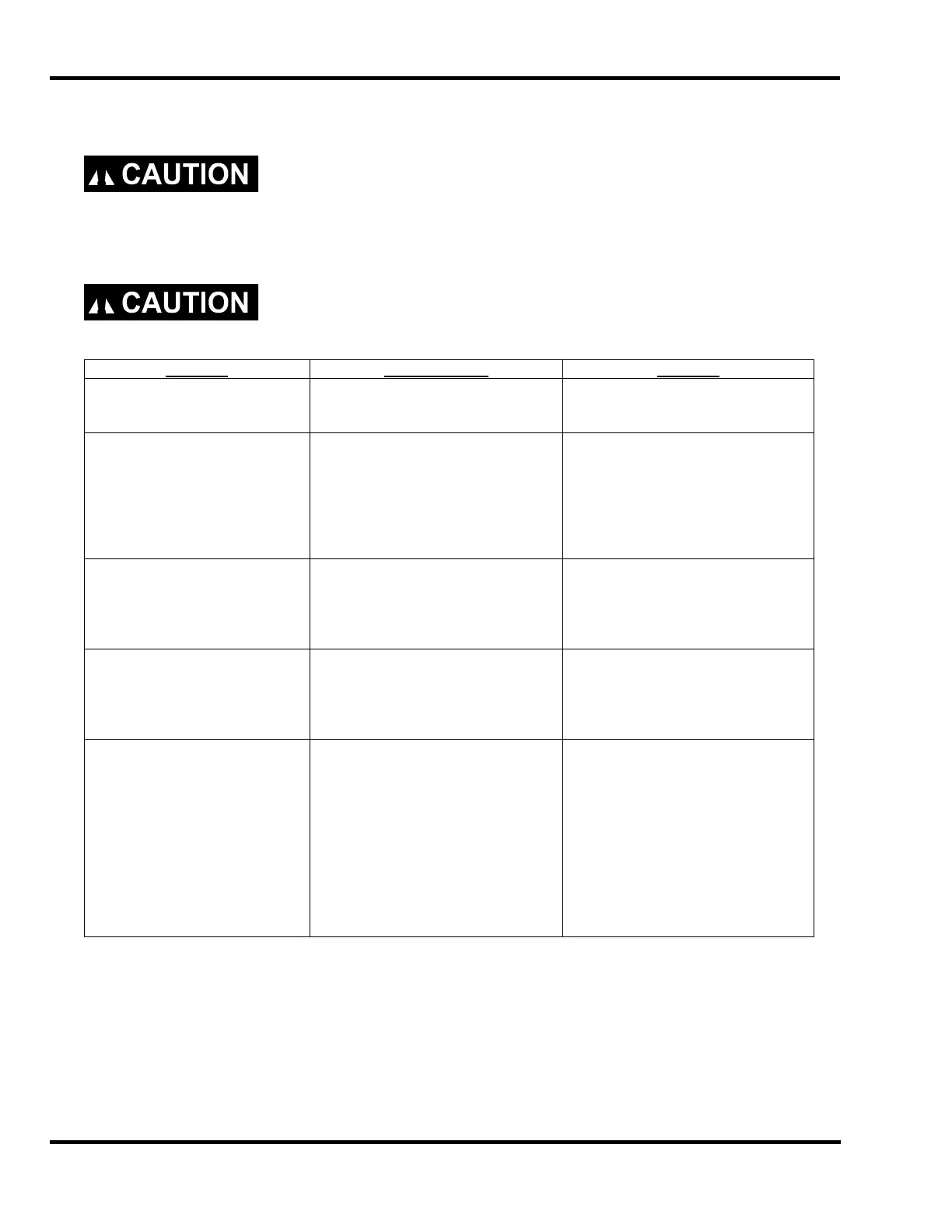

Power to machine

Tripped Circuit Breaker

Connect power

Reset Circuit Breaker

Relief valve in pump may be bad

or have dirt in it

Check oil level – may be low

Check voltage at machine – may

be low

Clean or replace relief valve or

pump

Add oil

Remove other machinery on line

or provide a dedicated line

3. Drill head won’t return

Check lift springs – may be

broken or stuck (replace if

necessary).

Pull down shafts froze in frame.

Pry up head, clean & oil shafts

Pry up head, clean & oil shafts

4. Drill head won’t come down

Check for broken lift spring – may

be jammed

Speed control valve out of

adjustment or defective

Replace spring

Try to readjust, may have to

replace

Dull drills

Check for low voltage

Drive belt may be loose

Check for paper plugging drills

Sharpen drills

(See above)

Adjust belt tension (See

Adjustment section of this

manual)

Clean out hollow drills – We

recommend cleaning and soaking

drills in oil overnight

Loading...

Loading...