8.0 Maintenance Guide

27

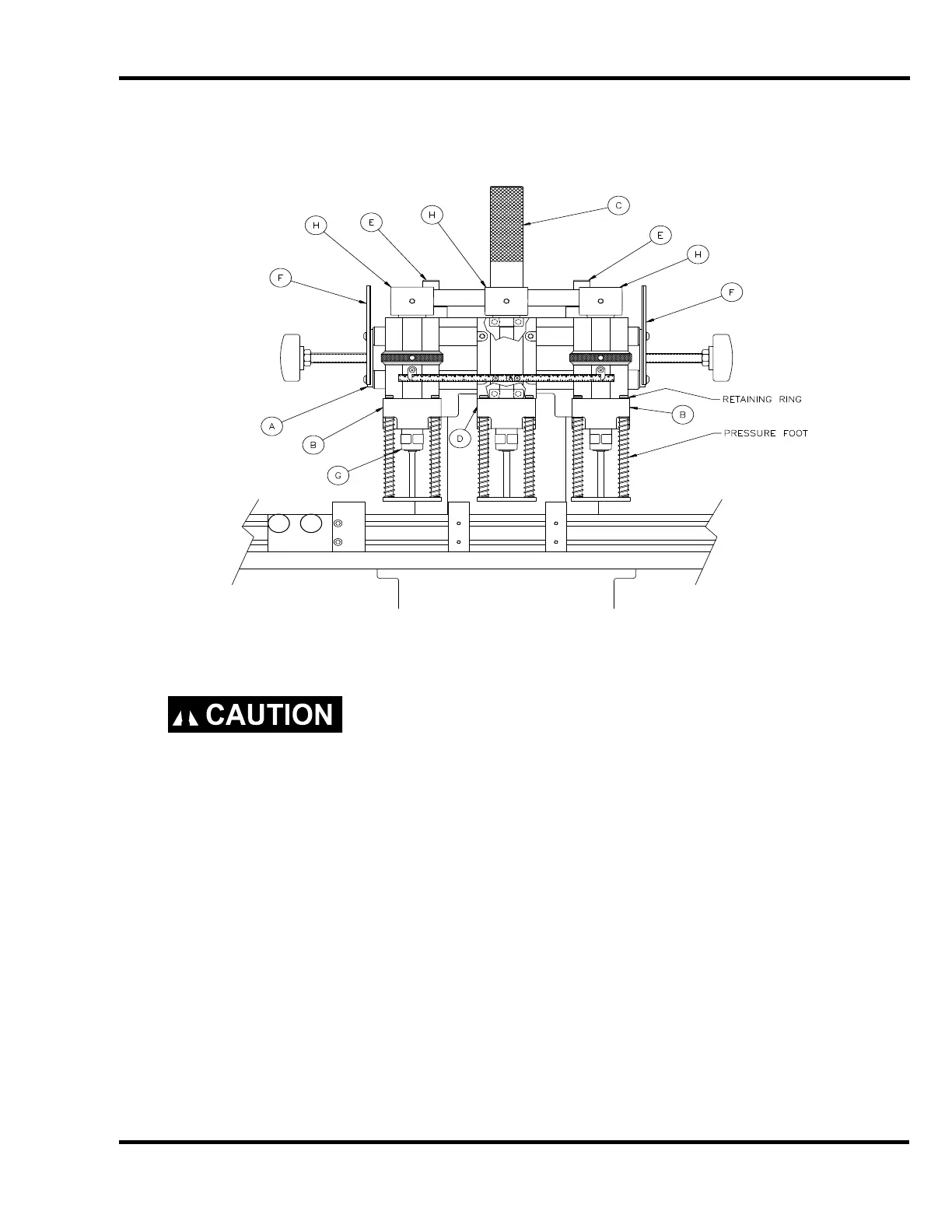

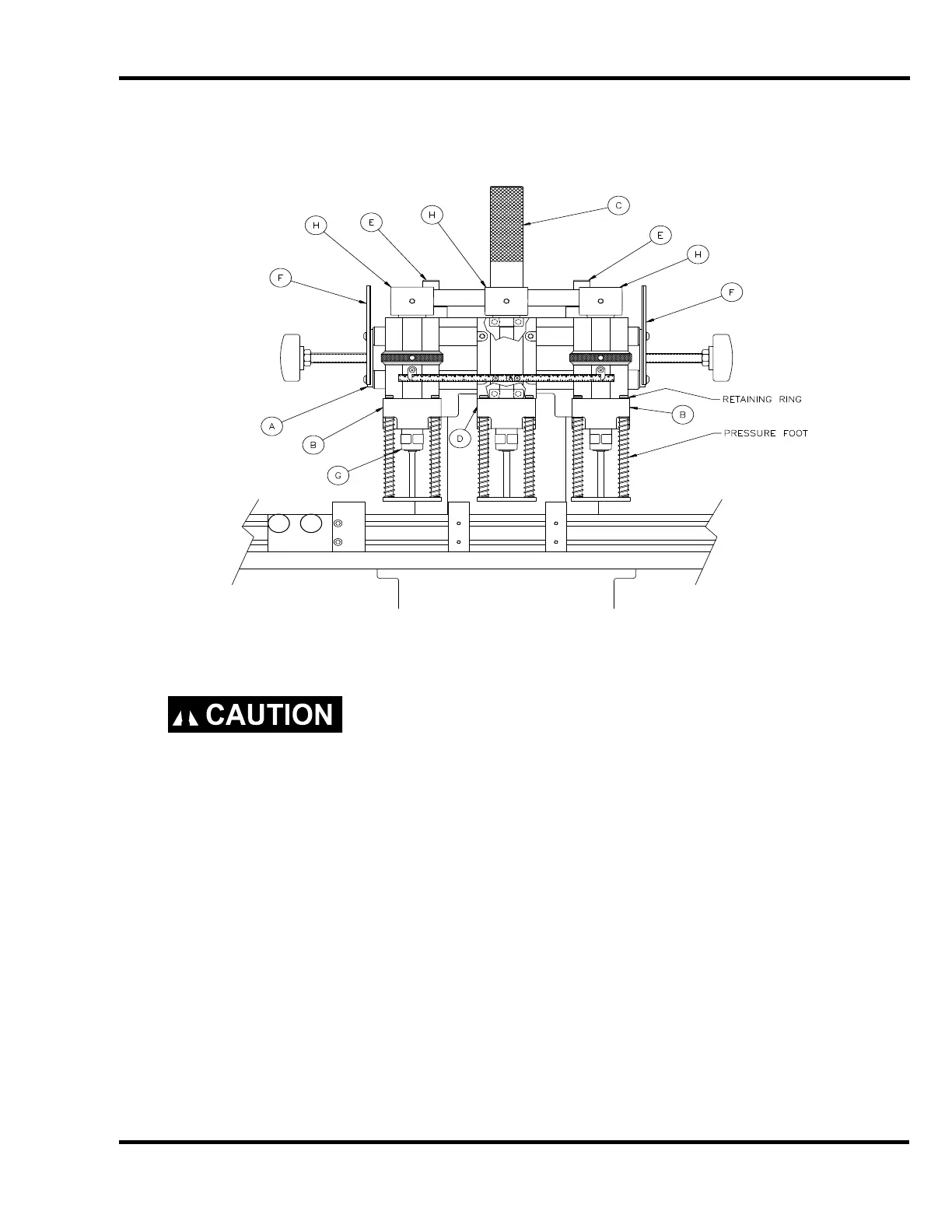

8.4 Drill Head Replacement

Figure 19

Always disconnect the power when cleaning, servicing, or lubricating your

drill, see Lock Out Procedures, page 5.

Through normal use, bearings will wear and need replacing. Signs of wear are excessive noise, heat,

or loose spindles.

Replacement Procedure:

1. Remove cover.

2. Remove belt.

3. Remove chip pan assembly.

8.4.1 Side Head Bearing Replacement

1. Remove end plate “A” and shield “F” from shaft.

2. Slide head off shafts.

3. Remove chip chute “B” from head.

4. Remove pulley “H” from spindle.

5. Tap spindle “G” out from head.

6. Tap out bearings (must use rod from opposite end of each bearing).

7. Tap the upper bearing (S-706) in place using a piece of wood between the hammer and the

bearing (an old drill block works fine).

Loading...

Loading...