8.0 Maintenance Guide

26

2. Use only one of the recommended oils or an ISO VG 100 Hydraulic Fluid equivalent. Oils

other than the recommended type will cause seals, cups and O-rings to deteriorate. See

Section 8.5.1 on page 28.

8.2.4 Yearly

1. Check all adjustments.

2. Tighten all screws.

3. Change hydraulic oil in reservoir. Oil may have to be changed more often if contamination of

any kind gets in the oil. (Capacity: 1-1/2 Quarts/1.4 liters)

4. Grease lift springs.

8.3 Adjustments

8.3.1 Table Position Adjustment

Set the backgauge to the 1” position. Drill a few sheets of paper and measure the distance between

the center of each hole to the edge of the paper. If it is not 1” (2.5 cm), loosen the (4) screws that

mount the table to the base and carefully move the table to compensate for the error. Tighten the

screws and drill some more paper. Repeat this procedure until the holes measure 1” (2.5 cm).

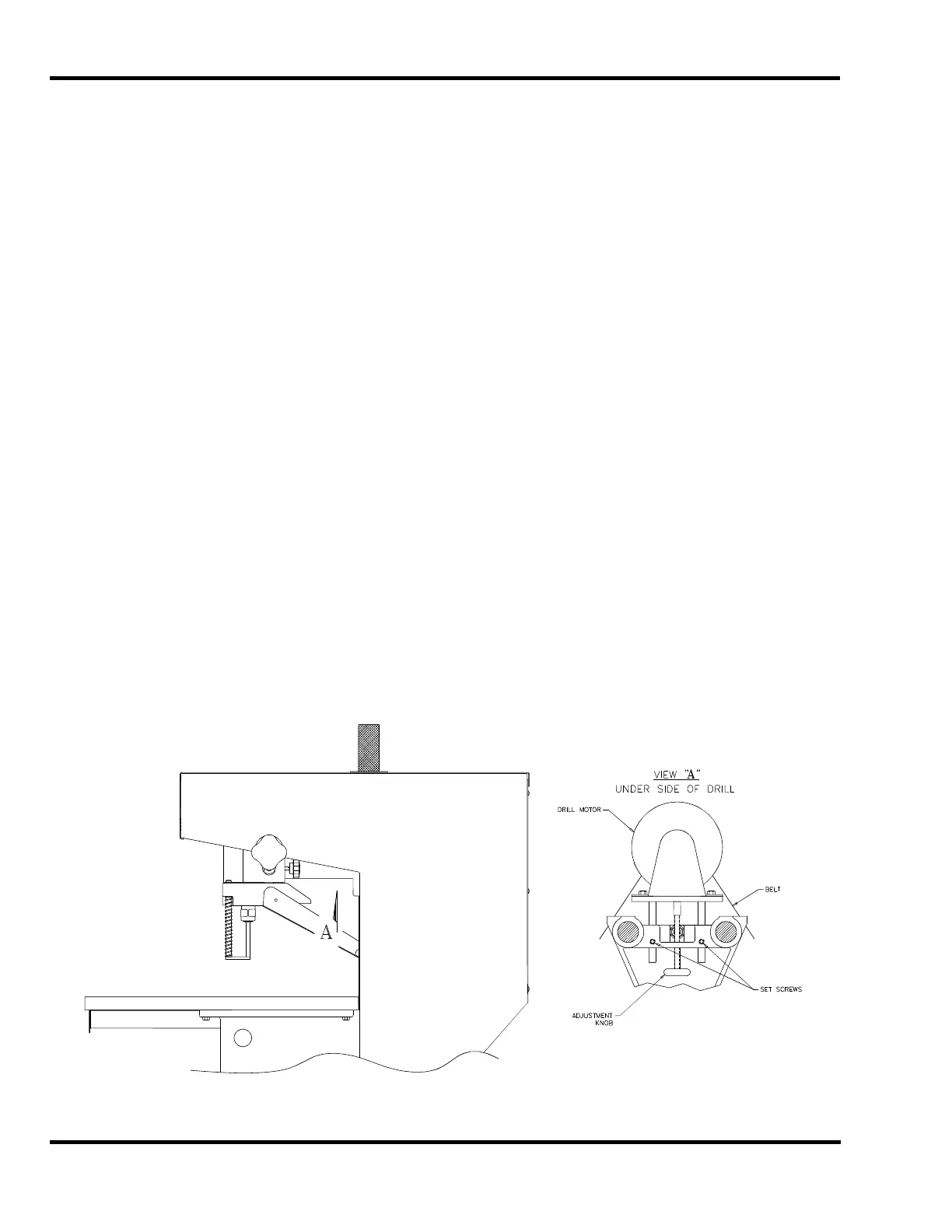

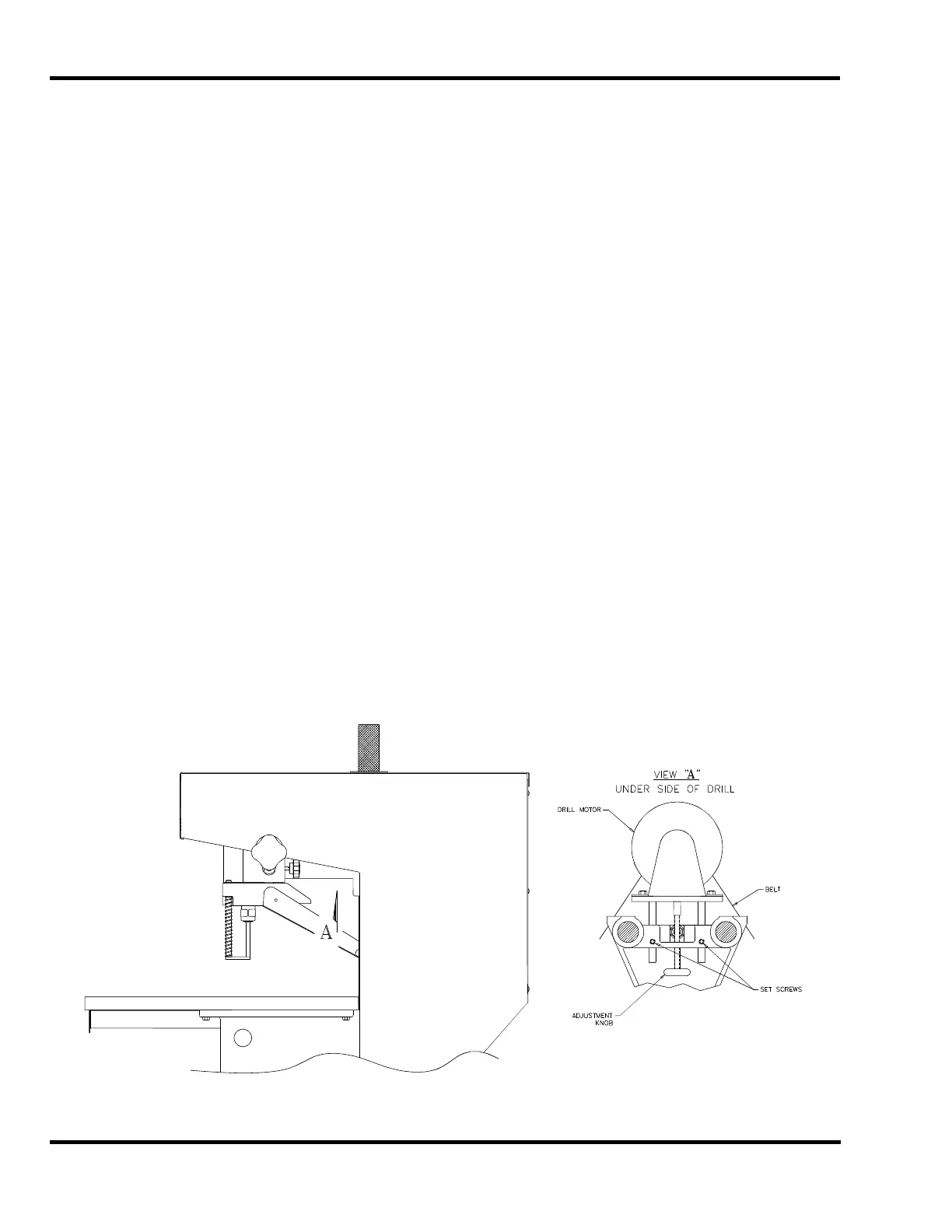

8.3.2 Belt Tightness Adjustment

Loosen the two set screws (Figure 18). Turn the Adjustment Screw (Figure 18) to move the motor in

and out as needed. The belt must be tight enough that it does not slip. Tighten both set screws

when finished.

Figure 18

Loading...

Loading...