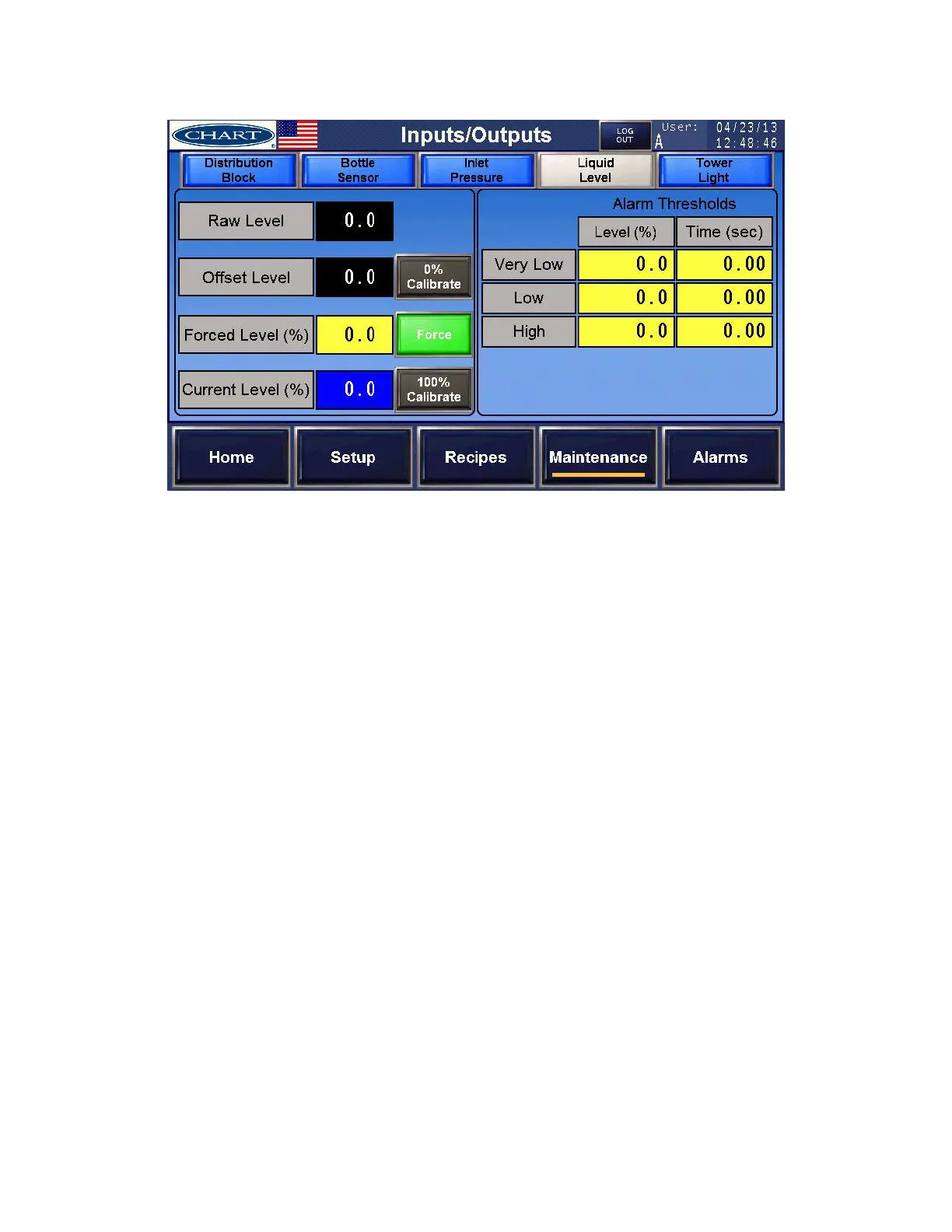

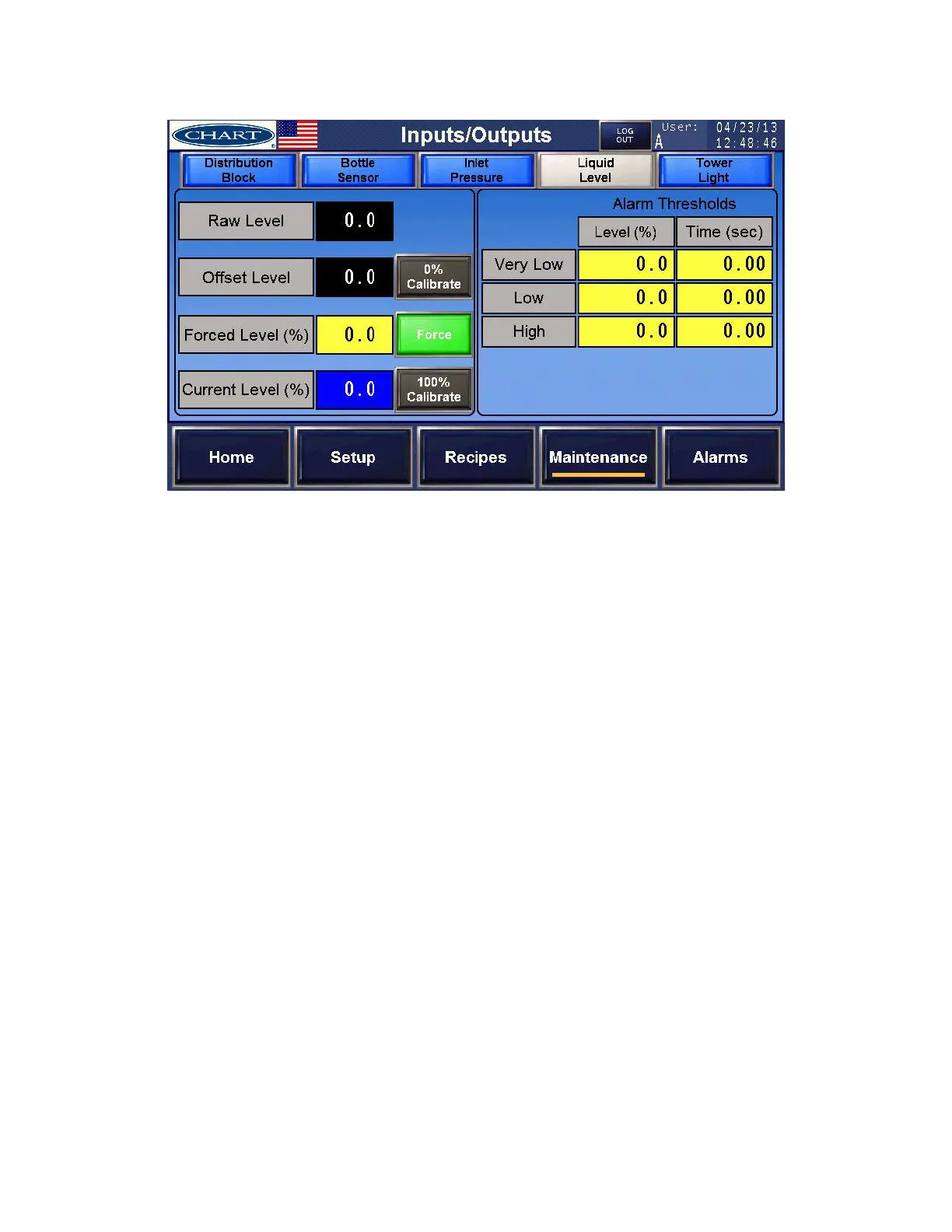

Liquid Level – calibrate and set alarm threshold for Liquid Level

a) Raw Level – This is the raw reading from the PLC analog input.

b) 0% Calibrate – Push this pushbutton when calibrating at the zero Liquid Level.

c) Offset Level – After calibrating the liquid level at zero level by pushing the ‘0% Calibrate’

pushbutton the raw reading will become the Offset Level.

d) 100% Calibrate – Push this pushbutton when calibrating at the 100% Liquid Level.

e) Current Level % - The blue box indicates the current liquid level.

f) Forced Level % - You can force a liquid level by typing a value in the yellow input box

and pressing the ‘Force’ toggle.

g) Alarm Thresholds – The thresholds low and high liquid level alarms can be set by typing

an alarm threshold % value and associated time before the alarms occurs into the yellow

input box.

Loading...

Loading...