THE EQUIPMENT. FAILURE TO

CAUSE INJURY OR DEATH.

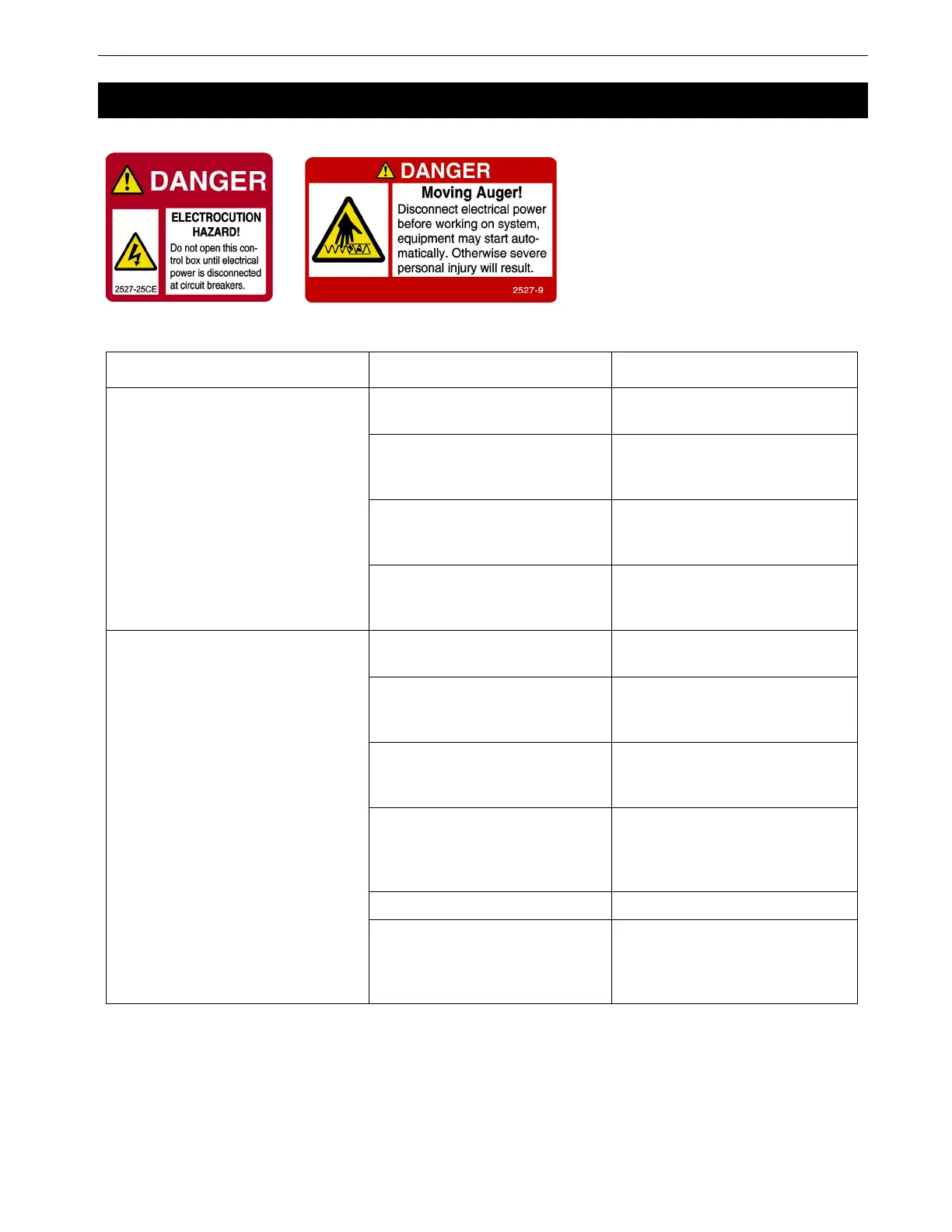

Problem Possible Cause Corrective Action

Delivery system will not run. No power to the system. Check circuits, fuses, and on-off

switches on the equipment.

Bin level switch has stopped

the system due to lack of feed

in the boot.

Check feed supply and for pos-

sible bridging.

Motor overloaded and stopped. Check for foreign material in the

line. Push the motor reset but-

ton.

Safety switch actuated in the

Control Unit (red pilot light will

be lit).

Determine reason for feed pack-

ing in the Control Unit. Feed

level switch out of adjustment?

Motor overloads after running

briefly.

Motor too small. Use recommended size motor

for line length.

Low voltage (motor runs slow

and overheats).

Check line voltage at the motor;

use adequate size wire in cir-

cuits.

Foreign object in the auger

(motor runs, stalls, then auger

spins in reverse).

Check auger line, pull auger to

remove objects.

Motor wired in reverse (motor

runs, stalls, no feed conveyed).

Disconnect power and change

wire connections (direct drive

power unit shaft at rear of motor

turns clockwise).

Boot Anchor tight. Check for Anchor binding.

Wet feed being conveyed or

allowed to stand in auger

tubes. Defective motor (over

heats without load).

Clean auger and tubes; avoid

conveying wet feed or empty

line after each feeding.

Replace motor.

Loading...

Loading...