Transmig 210, 250, 310, 330

DOC No: MIGTRN0001 Page 17 of 31

Issue No: 2 Date: 14/09/98

6.3 Digital Ammeter and Voltmeter (Standard for Transmig 330 Only)

Where fitted an average reading ammeter and voltmeter is provided to allow accurate monitoring

(5% tolerance) of welding current and voltage. Refer to section 9.1 on page 25 for the Improved

Current Accuracy Calibration Procedure for the Digital Meter.

The Digital Meter will display both welding current and voltage. To toggle between the current and

voltage readings depress the push button switch mounted below the meters display. See Figure 9 for

an example of current and voltage displays.

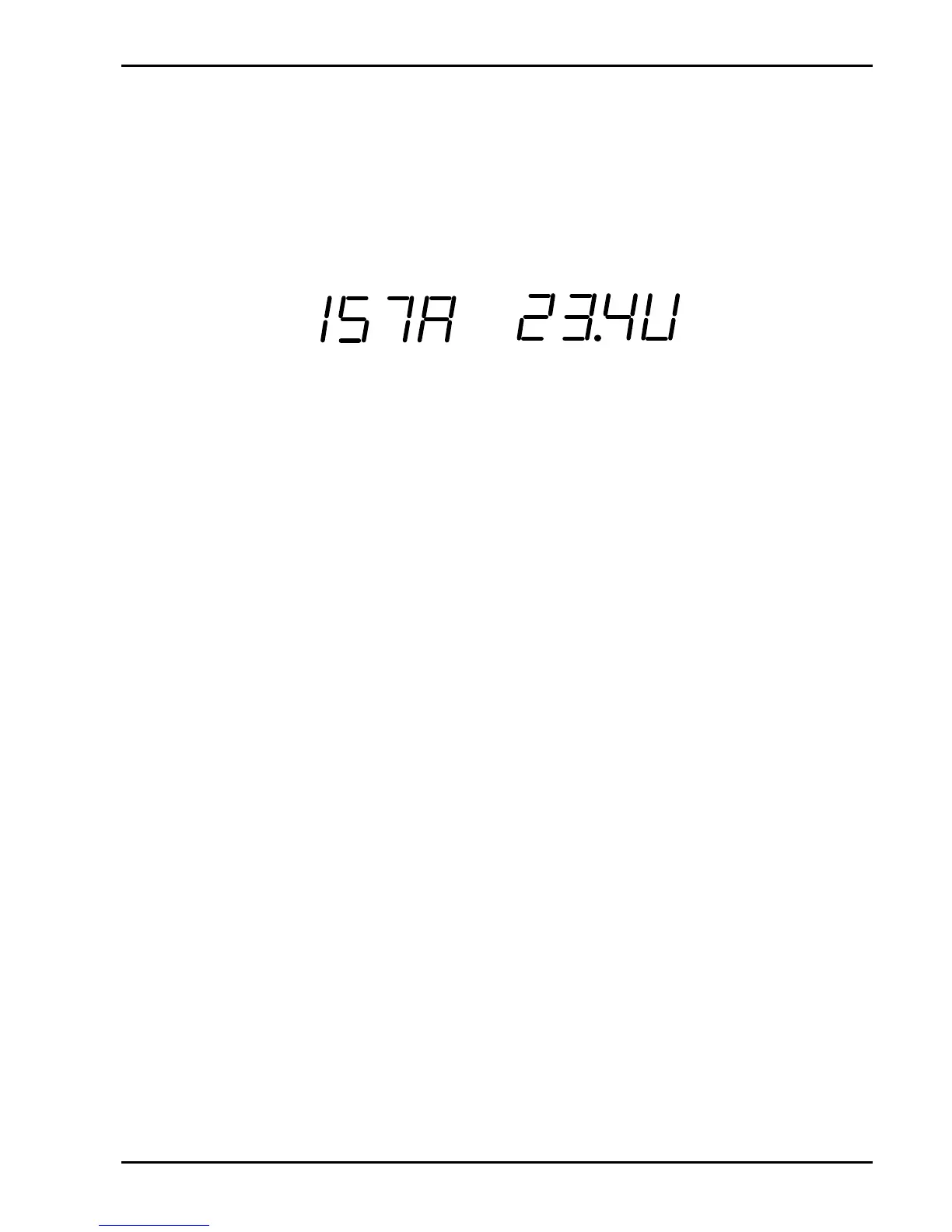

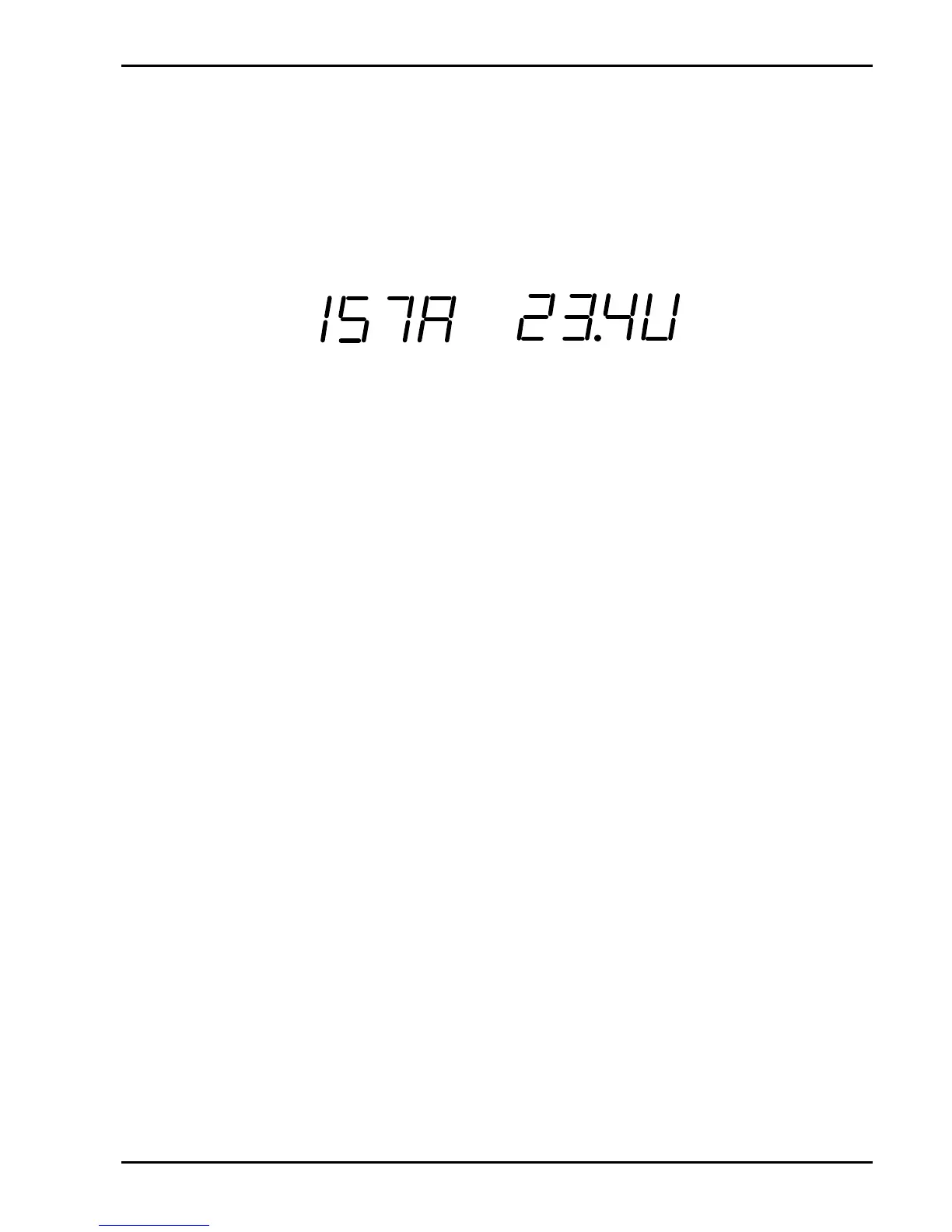

Value displayed for 157 Amp Value displayed for 23.4 Volts

Figure 9 - Examples of the digital read outs

6.4 Torch Polarity Lead (Compact Models Only)

This lead selects the welding voltage polarity of the electrode wire. Plug it into the positive welding

terminal ( + ) when using steel, stainless steel or aluminium electrode wire. Plug the Torch Polarity

Lead into the negative welding terminal ( - ) when using gasless electrode wire. If in doubt, consult

the manufacturer of the electrode wire for the correct polarity.

6.5 Positive and Negative Welding Terminals

Welding current flows from the Power Source via heavy duty bayonet type terminals. It is essential,

however, that the male plug is inserted and turned securely to achieve a sound electrical connection.

WARNING 5: Loose welding terminal connections can cause overheating and result in the

male plug being fused in the bayonet terminal.

6.6 Wirefeeder Control Socket (Remote Wirefeeder Models Only)

This socket accepts the male plug on the control cable from the Wirefeeder. The male plug should

be fully inserted into the control socket then locked into position by turning the retaining ring on the

male plug in a clockwise direction.

6.7 Thermal Overload

The critical component for thermal protection is the rectifier stack, which is fitted with a thermal

overload cutout device. If the overload operates then the machine should be left to cool for

approximately 15 minutes before resuming welding. There will be no danger of transformer damage

if the Power Source is operated within its duty cycle, refer to section 1.1 for an explain of duty cycle

and section 2 for the Power Source specifications.

Loading...

Loading...