Transmig 210, 250, 310, 330

Page 28 of 31 DOC No: MIGTRN0001

Date: 14/09/98 Issue No: 2

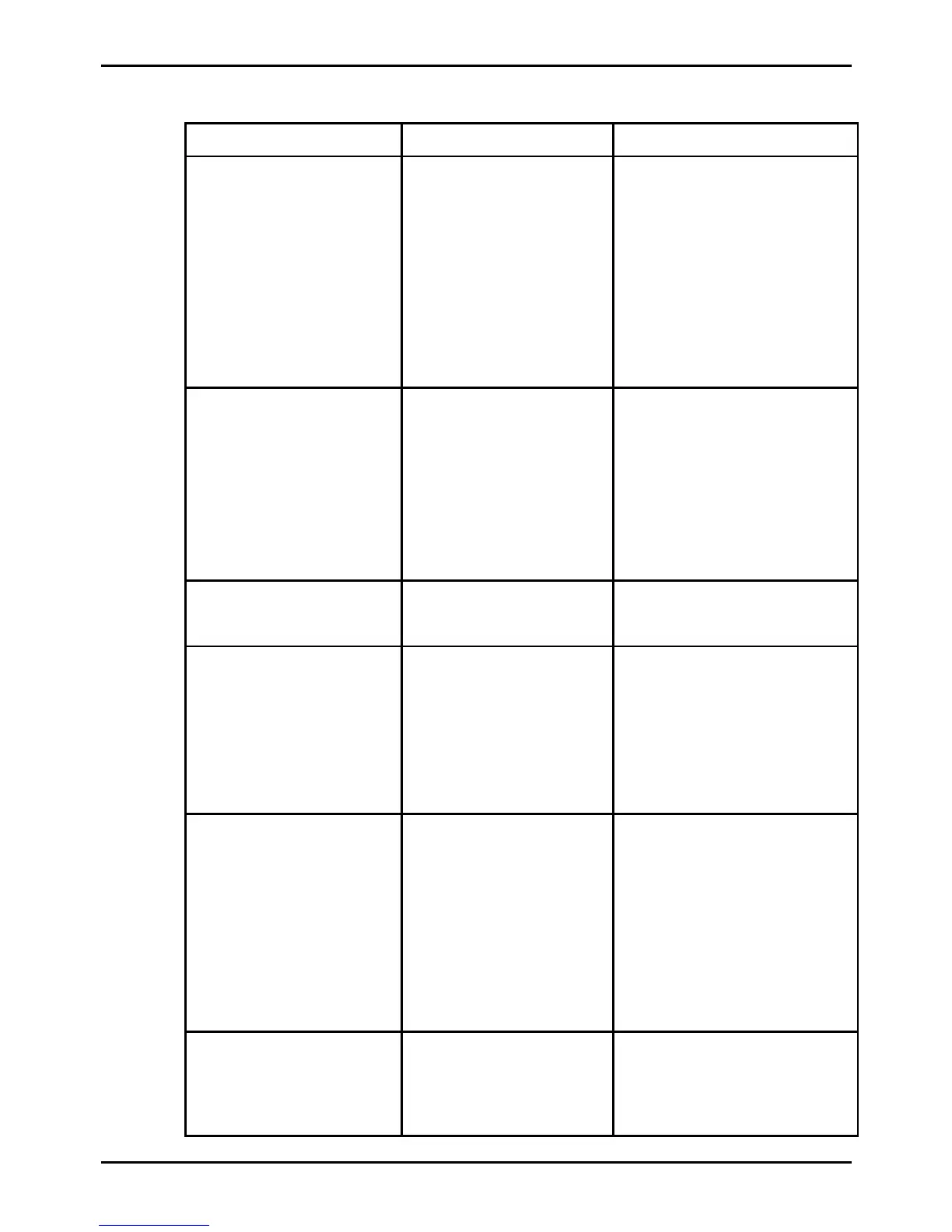

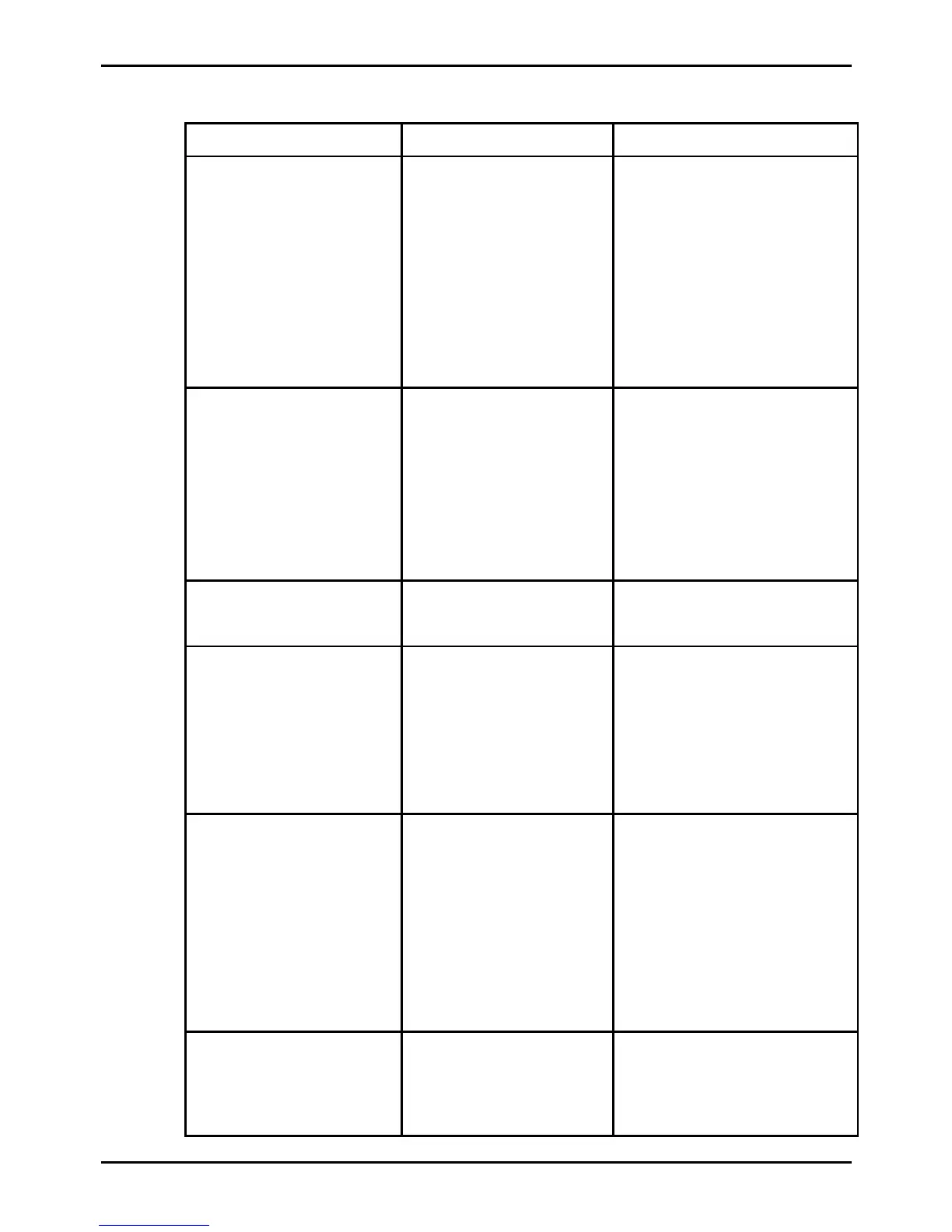

10.2 Welding Problems

FAULT CAUSE REMEDY

1 Undercut AWelding arc voltage too

high.

AReduce voltage by reducing the

Voltage Control switches posi-

tions or turn the Wirespeed con-

trol knob clockwise.

BIncorrect torch angle BAdjust angle

CExcessive heat input CIncrease the torch travel speed or

reduce welding current by

reducing the Voltage Control

switches positions and turn the

Wirespeed control knob anti-

clockwise.

2 Lack of penetration AWelding current too low AIncrease welding current by

increasing turn the Wirespeed

control knob clockwise and

increasing Voltage Control

switch positions.

BJoint preparation too

narrow or gap too tight

BIncrease joint angle or gap

CShielding gas incorrect CChange to a gas which gives

higher penetration

3 Lack of fusion Arc voltage to low Increase Arc voltage by

increasing the Voltage Control

switches position.

4 Excessive spatter AArc voltage too high ALower voltage by reducing the

Voltage Control switches

positions or turn the Wirespeed

control knob clockwise.

BArc voltage too low BRaise voltage by increasing the

Voltage Control switches or turn

the Wirespeed control knob anti-

clockwise.

5 Irregular weld shape AIncorrect voltage and

current settings. Convex,

Arc voltage too low

Concave,

voltage too high.

AAdjust voltage and current by

adjusting the Voltage Control

switches positions and the

Wirespeed control knob.

BWire is wandering BReplace contact tip

CIncorrect shielding gas CCheck gas selection

DInsufficient or excessive

heat input

DAdjust the Wirespeed control

knob or the Voltage Control

switches.

6 Arc does not have a crisp

sound that short arc

exhibits when the wirefeed

speed and voltage are

adjusted correctly.

The MIG torch has been

connected to the wrong

voltage polarity on the front

panel.

Connect the MIG torch to the

positive welding terminal (+) for

solid wires and gas shielded flux

cored wires.

Loading...

Loading...