Transmig 210, 250, 310, 330

DOC No: MIGTRN0001 Page 29 of 31

Issue No: 2 Date: 14/09/98

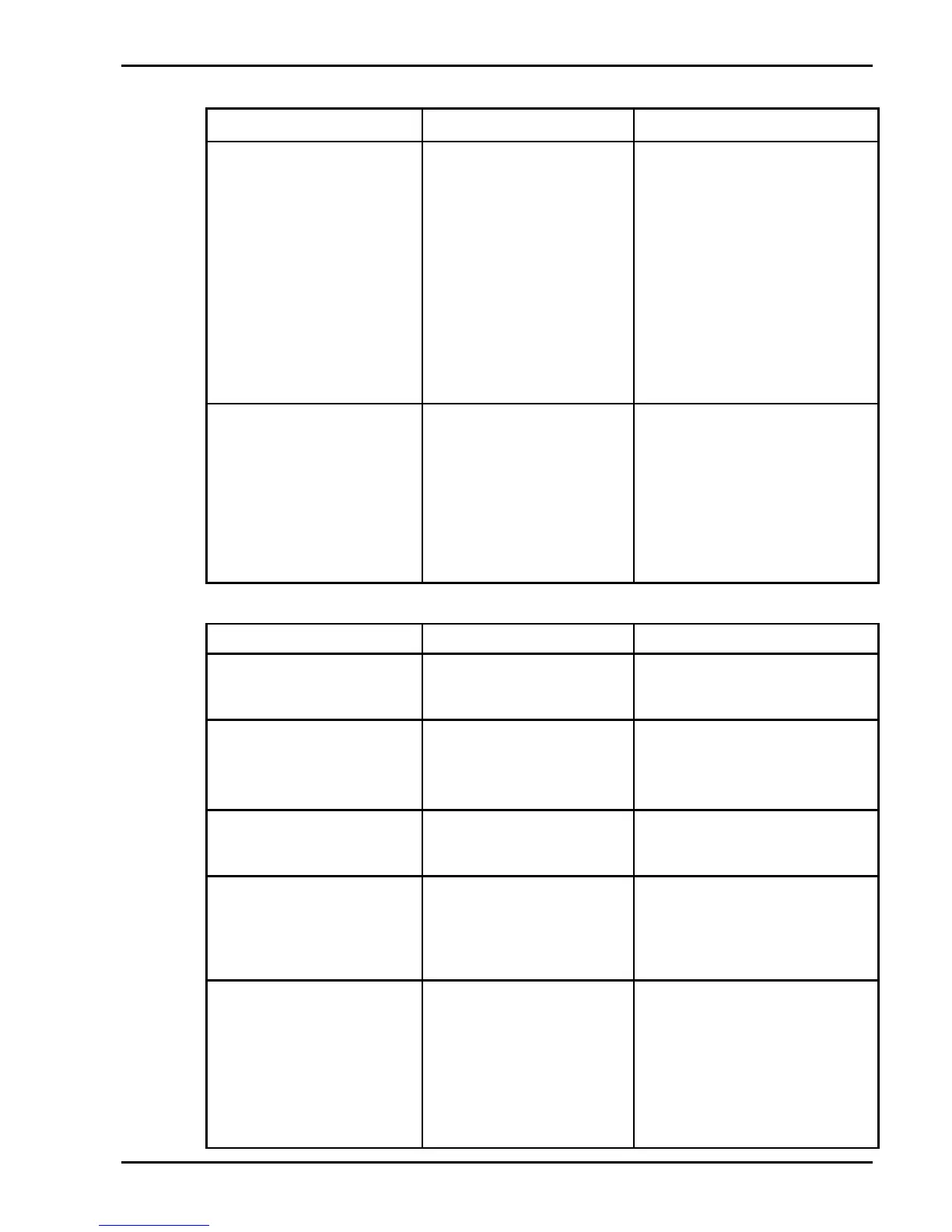

Welding Problems (continued)

FAULT CAUSE REMEDY

7 Weld cracking AWeld beads too small ADecrease torch travel speed

BWeld penetration narrow

and deep

BReduce current and voltage and

increase the MIG Torch travel

speed or select a lower

penetration shielding gas.

CExcessive weld stresses CIncrease weld metal strength or

revise design

DExcessive voltage DDecrease voltage by reducing the

Voltage Control switches.

ECooling rate too fast ESlow the cooling rate by

preheating part to be welded or

cool slowly.

8 Cold weld puddle AFaulty rectifier unit AHave an Accredited CIGWELD

Service Agent test then replace

the faulty component.

BLoss of a phase in the

Mains supply voltage.

BCheck mains power

CLoose welding cable

connection.

CCheck all welding cable

connections.

DLow Mains supply voltage DContact supply authority

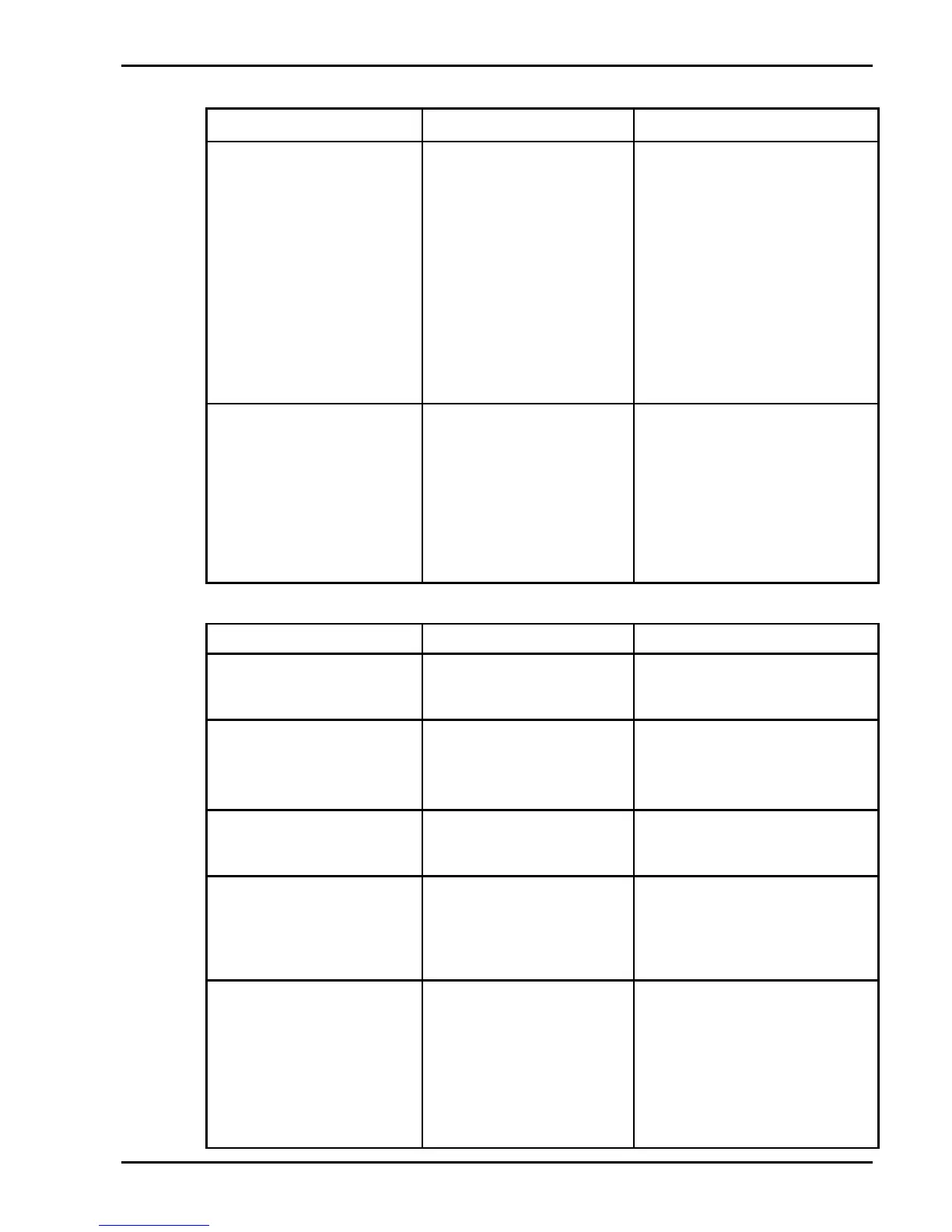

10.3 Power Source Problems

FAULT CAUSE REMEDY

1 Indicator light is ON but

welding arc can not be

established.

Coarse Voltage Control

switch is in the STANDBY

position.

Switch the Coarse Voltage

Control switch to a welding

setting.

2 Mains supply voltage is

ON. Indicator light is not lit

and welding arc can not be

established.

A

B

Primary fuse is blown.

Broken connection in

primary circuit.

A

B

Replace primary fuse.

Have an Accredited CIGWELD

Service Agent check primary

circuit.

3 Mains indicator light is not

lit but welding arc can be

established.

Burnt out Indicator light. Have an Accredited CIGWELD

Service Agent replace Indicator

light.

4 Mains supply voltage is

ON and Indicator light is lit

but when the torch trigger

switch is depressed nothing

happens.

Torch trigger switch leads

are disconnected.

Reconnect.

5 Mains supply voltage is

ON, no wire feed but gas

flows from the MIG Torch

when the torch trigger

switch is depressed.

AElectrode wire stuck in

conduit liner or contact tip

(burn-back jam).

ACheck for clogged / kinked MIG

Torch conduit liner or worn

contract tip. Replace faulty

components.

BFaulty control PCB BHave an Accredited CIGWELD

Service Agent investigate the

fault.

Loading...

Loading...