Transmig 210, 250, 310, 330

Page 30 of 31 DOC No: MIGTRN0001

Date: 14/09/98 Issue No: 2

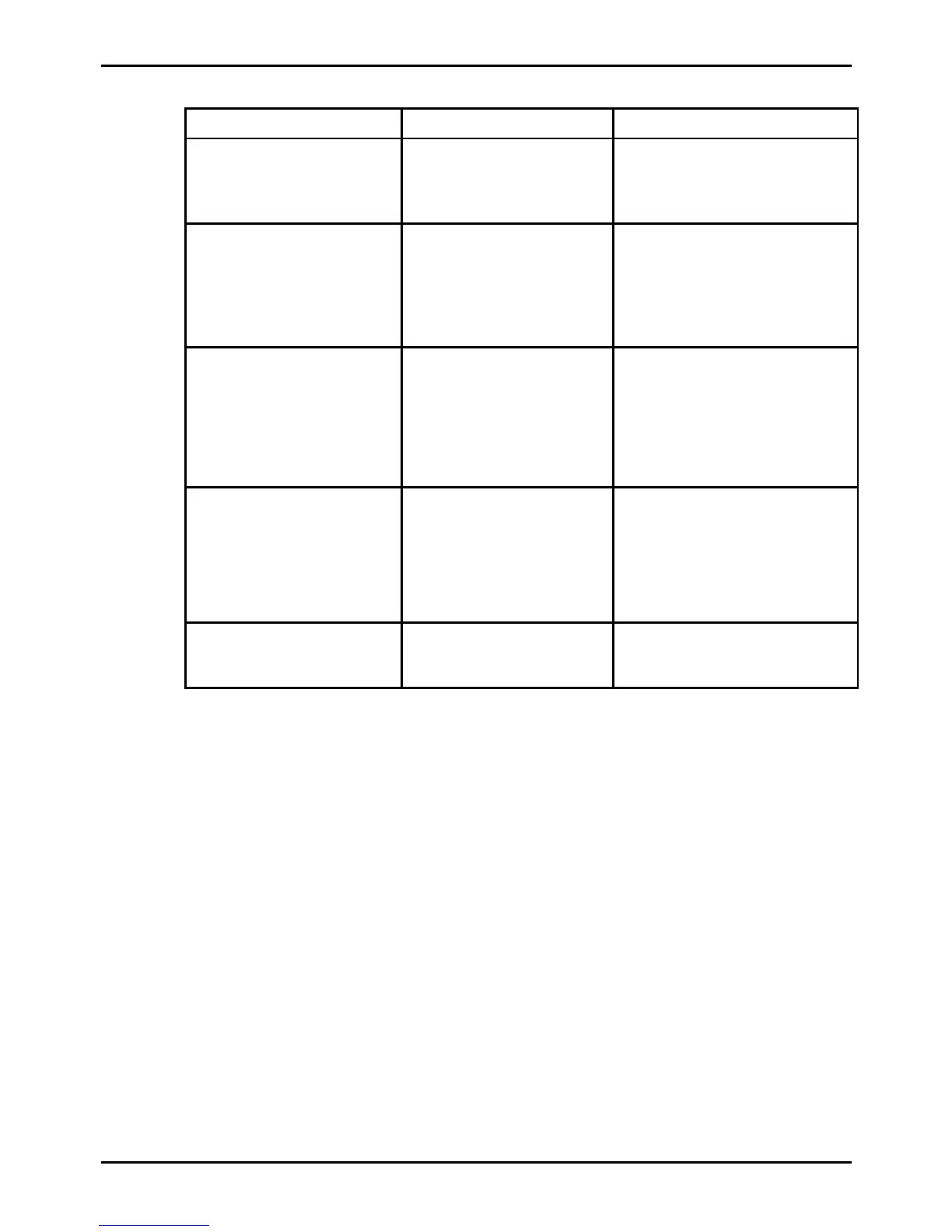

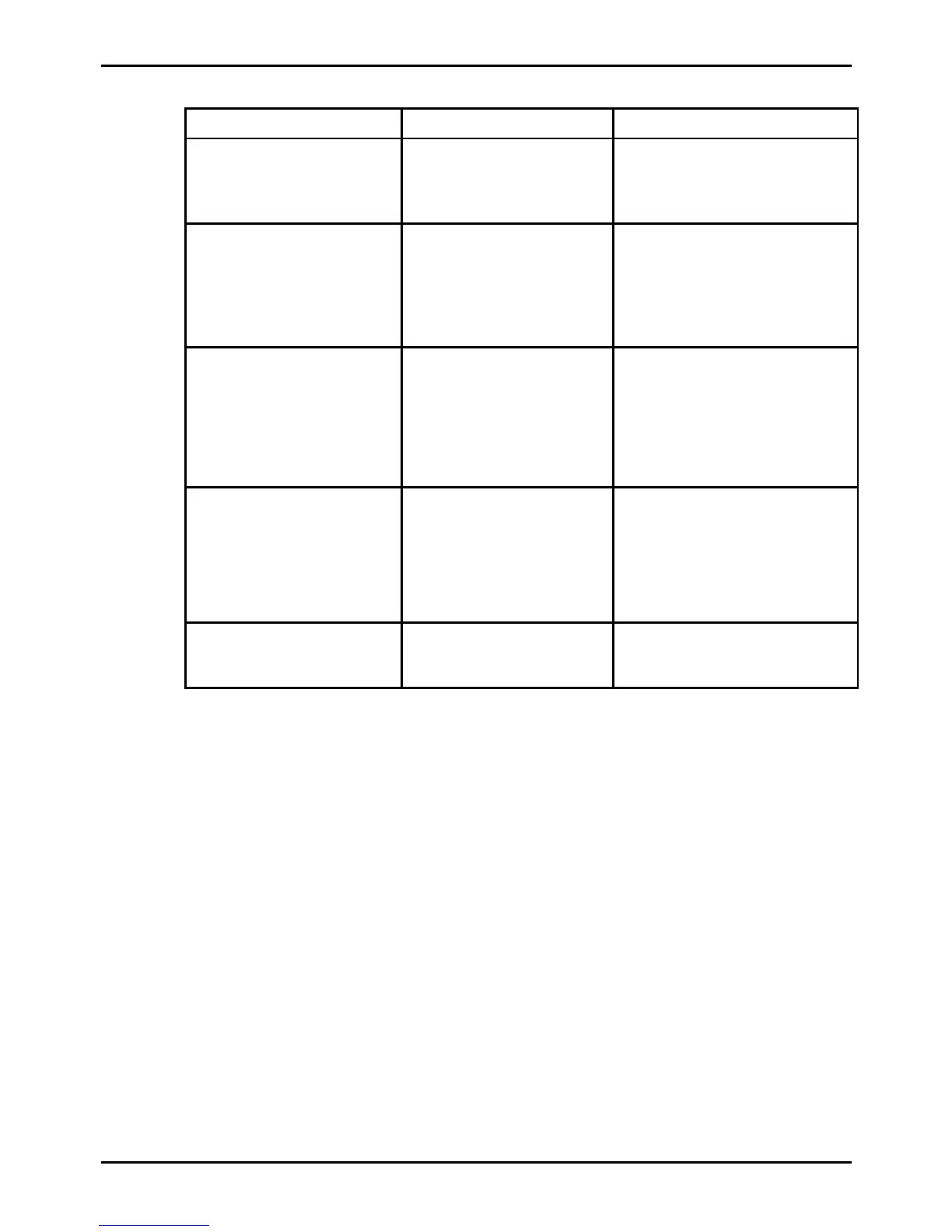

Power Source Problems (continued)

FAULT CAUSE REMEDY

6 Wire feeds when the torch

trigger switch is depressed

but arc can not be

established.

Poor or no work lead

contact.

Clean work clamp area and

ensure good electrical contact.

7 Mains supply voltage is

ON and contactor in the

Power Source operates but

wire does not feed when the

torch trigger switch is

depressed.

TWECO Torch has been

damaged internally, trigger

wires are making contact

with welding power cable.

Have an Accredited CIGWELD

Service Agent repair torch &

replace PCB.

8 Jerky wire feed AWorn or dirty contact tip AReplace

BWorn feed roll. BReplace

CExcessive back tension

from wire reel hub.

CReduce brake tension on spool

hub

DWorn, kinked or dirty

conduit liner

DClean or replace conduit liner

9 No gas flow AGas hose is cut. AReplace or repair.

BGas passage contains

impurities.

BDisconnect gas hose from the

rear of Power Source or wire-

feeder then raise gas pressure

and blow out impurities.

CGas regulator turned off. CTurn on.

10Gas flow continues after

the torch trigger switch has

been released.

Gas valve has jammed open

due to impurities in the gas

or the gas line.

Have an Accredited CIGWELD

Service Agent repair or replace

gas valve.

Loading...

Loading...