SERVICE 8-4 0-5492

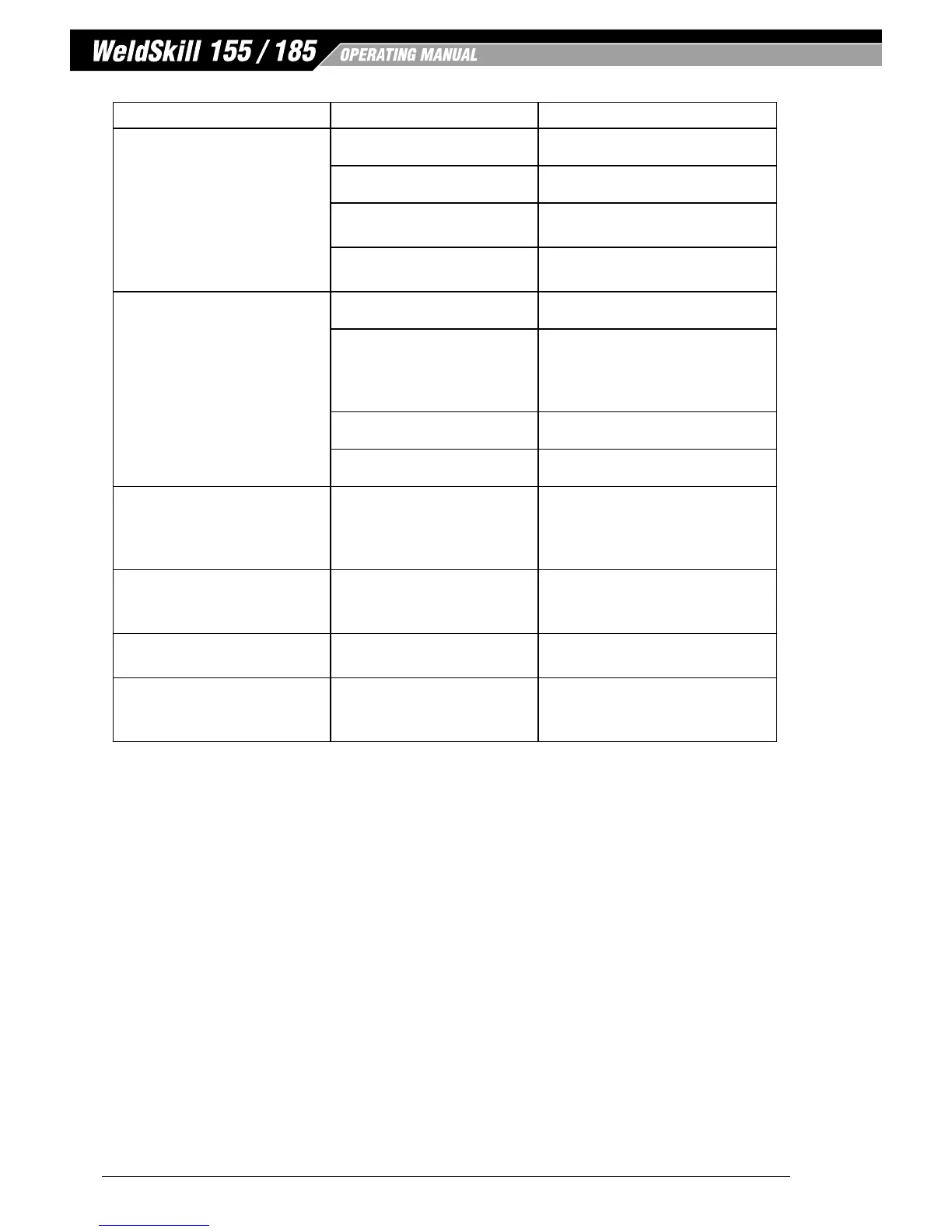

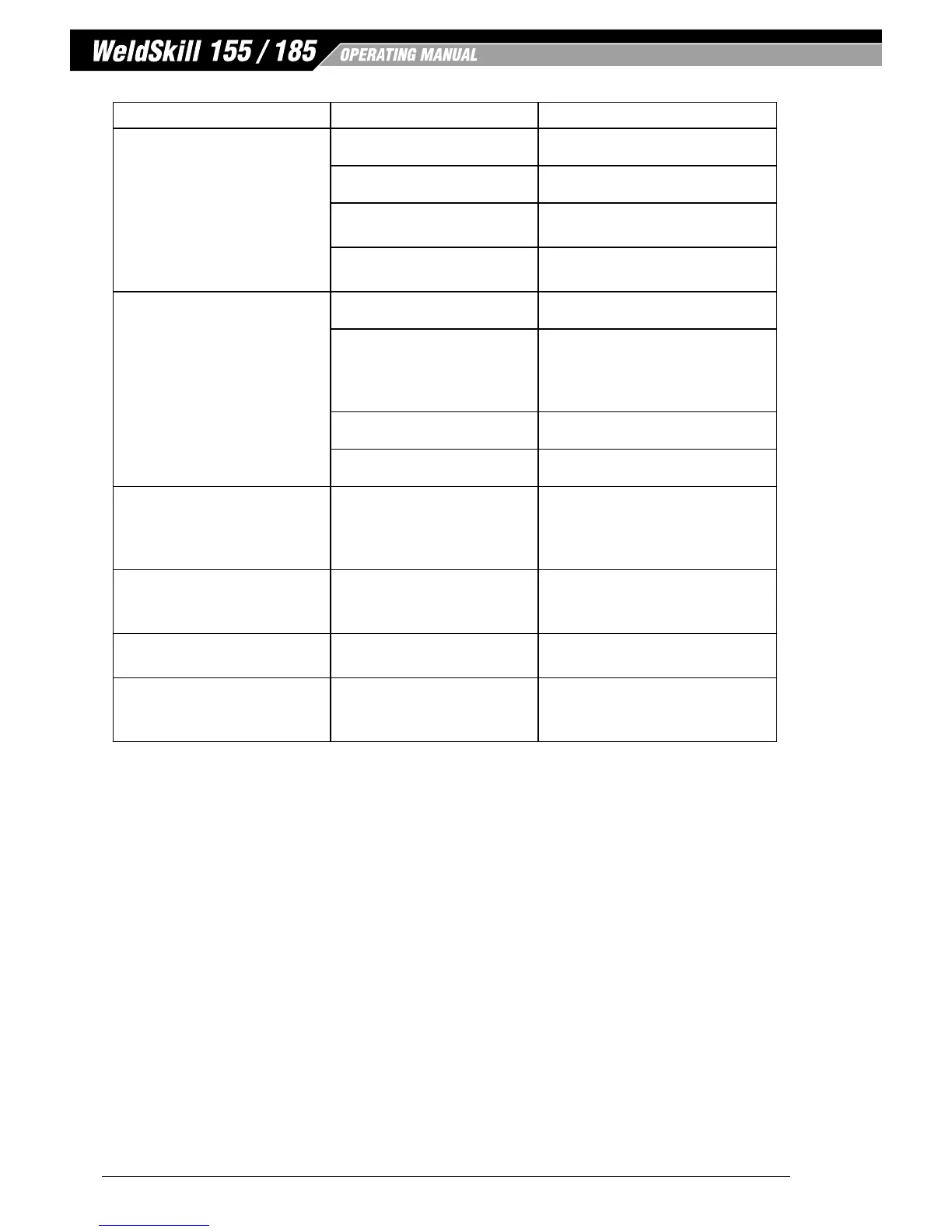

PROBLEM CAUSE REMEDY

9 Inconsistent wire feed. A Worn or dirty contact tip. A Replace if necessary.

B Worn feed roll. B Replace.

C Excessive brake tension on

wire reel hub.

C Reduce brake tension on spool

hub

D Worn, kinked or dirty

conduit liner

D Clean or replace conduit liner

10 No gas flow in MIG mode. A Gas hose is damaged. A Replace or repair.

B Gas passage contains

impurities.

B Disconnect gas hose from

the rear of power source

or wirefeeder and blow out

impurities.

C Gas regulator turned off. C Turn on regulator.

D Empty gas cylinder. D Replace gas cylinder.

11 Gas flow continues after

the torch trigger switch

has been released (MIG

mode).

Gas valve has jammed

open due to impurities in

the gas or the gas line.

Have an accredited CIGWELD

service provider repair or

replace gas valve.

12 Power indicator will not

illuminate and welding arc

cannot be established.

The mains supply voltage

has exceeded voltage

limits of the power source.

Ensure that the mains supply

voltage is within 240VAC ±

15%.

13 TIG electrode melts when

arc is struck.

TIG torch is connected to

the (+) VE terminal.

Connect the TIG torch to the (-)

VE terminal.

14 Arc flutters during TIG

welding.

Tungsten electrode is

too large for the welding

current.

Select the correct size of

tungsten electrode. Refer to

Table 6-1.

Table 8-1

Loading...

Loading...