Page 8 CI Man u al

If set up for a fi lter, in Step 7F set Volume Capacity in M

3

; in Step 8F select Regeneration Time Option “on 0”; and in Step 4I

select Day Override “oFF”.

NOTE: If the control valve is in an error state during regeneration mode the MAV will close the B port and keep open the A port

until the error is corrected and reset.

WS1, WS1.25

and WS1.5 Valves

WS2

Valve

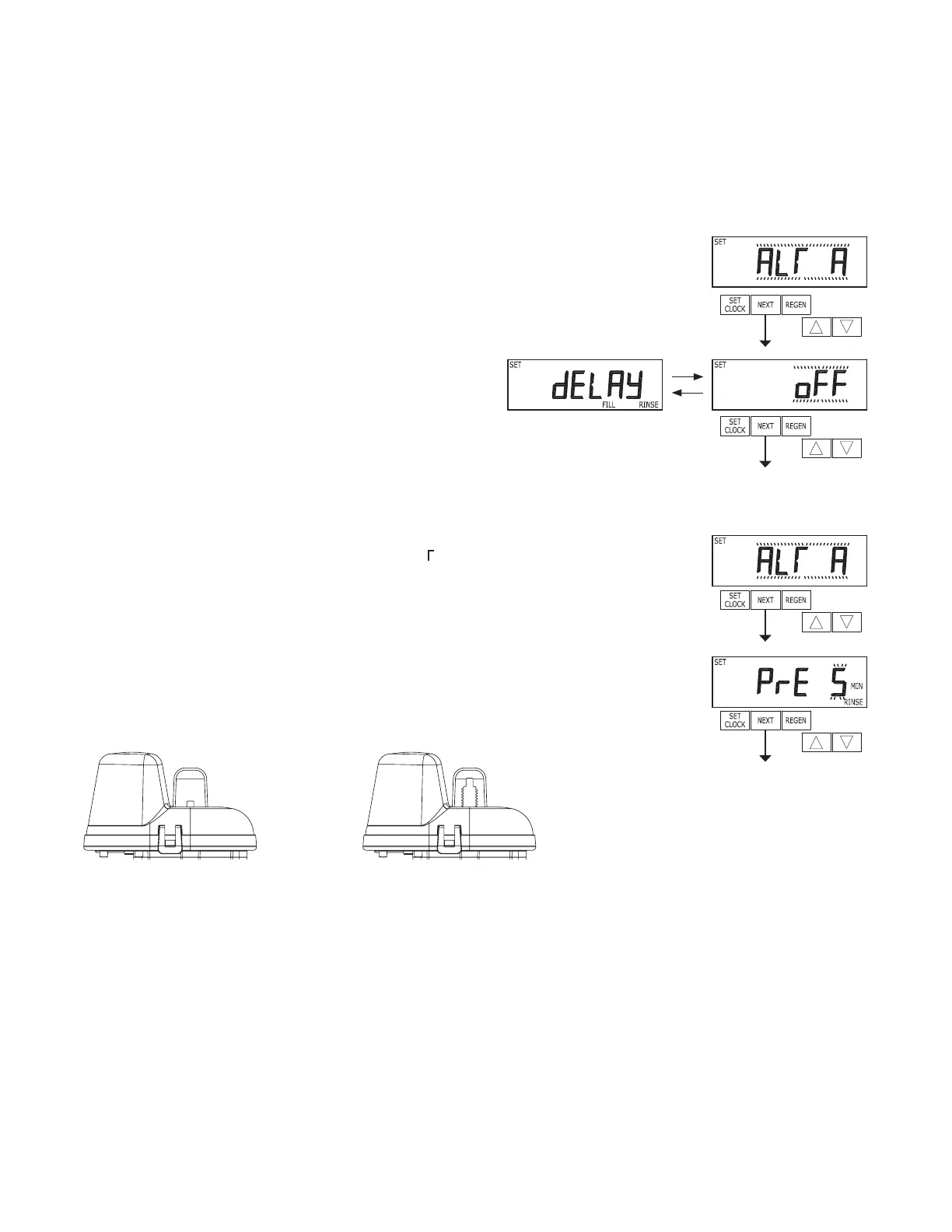

For Clack Corporation alternator systems using WS1, WS1.25 and

WS1.5 valves there will be an option to delay the last two cycles

of regeneration (only “Rinse” and “Fill”). This feature

splits the regeneration into two portions. The fi rst portion of the

regeneration will start immediately and all programmed cycles

before the “Rinse” and “Fill” cycles will be performed. After

all programmed cycles before “Rinse” and “Fill” are completed

the control valve will drive to the service position (displaying

“Delayed Rinse + Fill Pending”). When the volume of the on-

line unit is depleted to 10% of its programmed capacity, the

control valve will be triggered to fi nish the second portion of the

regeneration. Once “Rinse” and “Fill” are completed, the valve

will re-enter Standby mode until requested to come on-line for

Service.

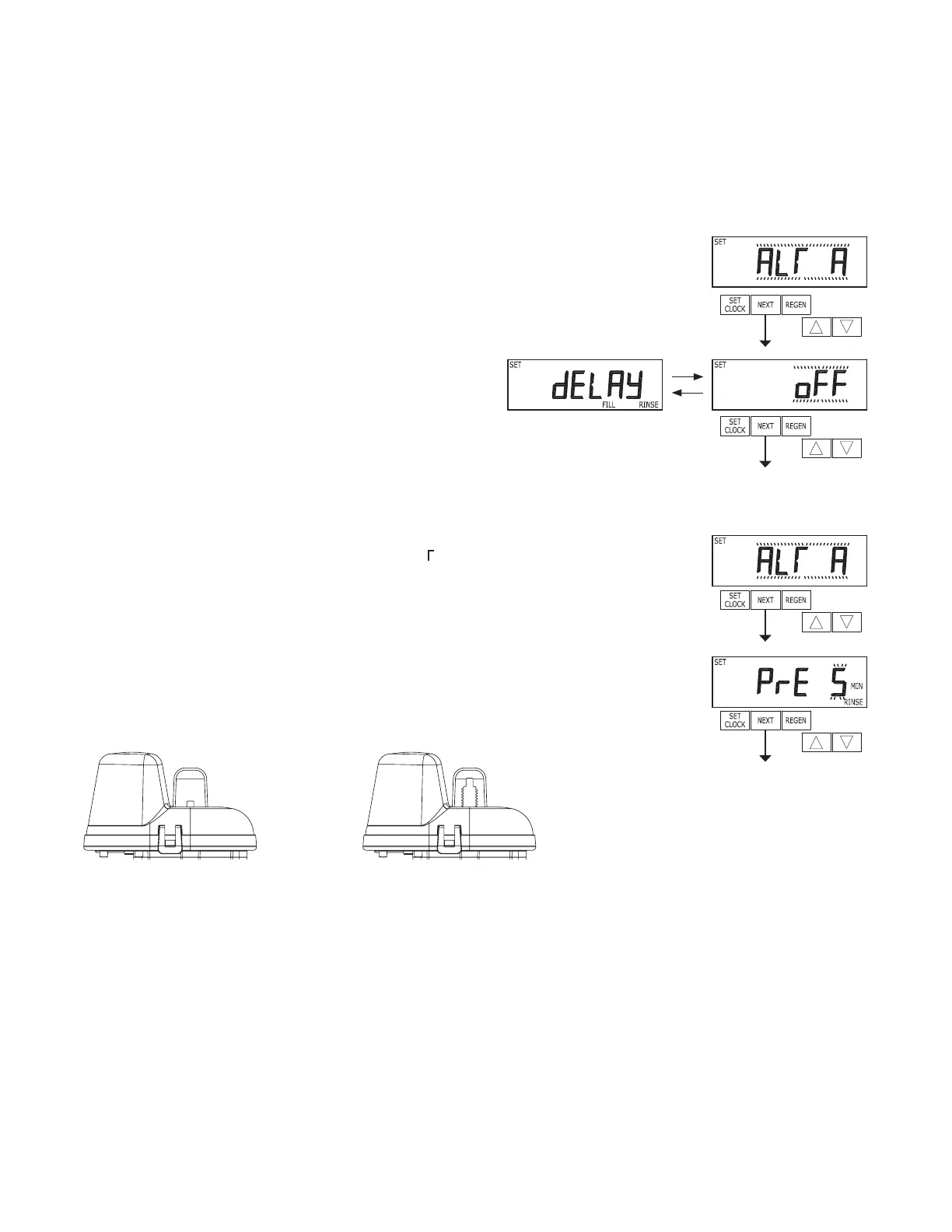

For Clack Corporation alternator systems using the WS2 valve,

when NEXT is pressed after selecting ALT A or ALT b, a display

will allow the user to set the amount of pre-service rinse time for

the stand by tank just prior to returning to service. With 1.0 set,

this same display appears and is set in a similar manner.

Retracted

Valve “A” in Service Position =

MAV piston rod Retracted

Extended

Valve “B” in Service Position = MAV

piston rod Extended

Note: Clack Twin Alternator Operations

• Twin alternating systems can be programmed with a day override setting combined with the normal volume-based

regeneration programming. A twin alternating system in this confi guration will then regenerate based on the volume used or

the day override if there is a period of low water usage.

• Twin alternating systems can be programmed as a time clock only based regenerating system. In this confi guration, the days

remaining are counted only on the unit that is in service. The unit in Stand-by Mode only notes days in diagnostics, which

results in time clock only twin regeneration initiation.

• Twin alternating systems can be programmed for a delayed regeneration time. The system will allow an immediate transfer

of the MAV to switch tanks and place a fully regenerated unit in service once a unit becomes exhausted. The exhausted unit

will then be placed into Stand-by Mode and allowed to have a delayed regeneration at the pre-set time.

Loading...

Loading...